Selecting the Right Cable Lugs in the UAE: A Guide for Engineers

Choosing the right cable lug is a critical decision for the safety and reliability of any electrical system in the UAE. In a climate where extreme heat, humidity, and dust are the norm, a weak connection can lead to catastrophic failures, costly equipment downtime, and serious safety hazards. This guide provides practical insights for engineers, panel builders, and electricians across the GCC.

Why Cable Lugs Are the Most Critical Link in Your Electrical System

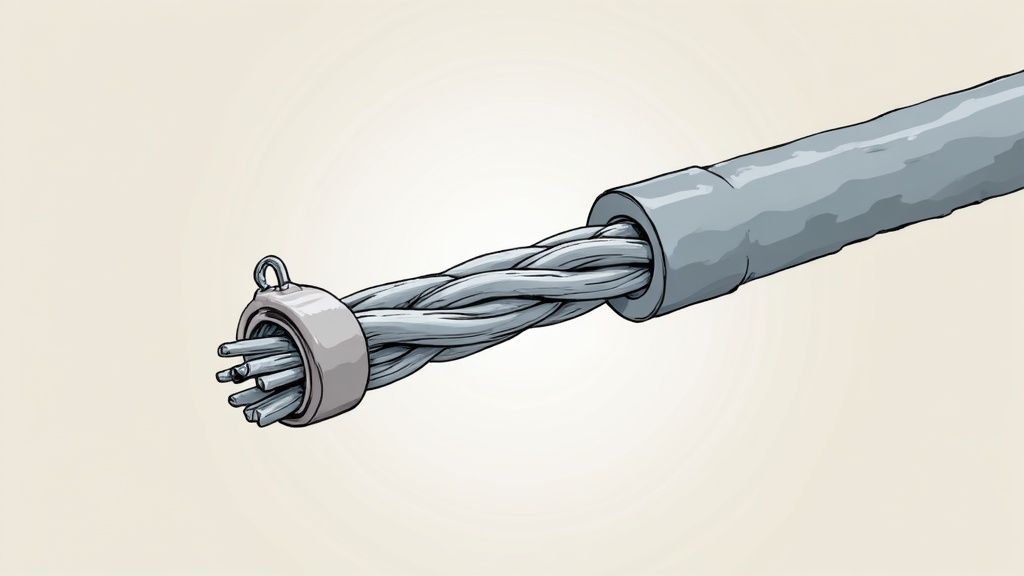

A cable lug is the crucial mechanical connector that terminates a power cable, allowing it to be securely attached to equipment like a terminal block or busbar. An improperly chosen lug can compromise an entire high-performance electrical assembly, directly impacting system longevity, efficiency, and safety. In a region where ambient temperatures can exceed 50°C, standard components are simply not sufficient.

For professionals across the GCC, understanding the different cable lugs types is non-negotiable. A poor choice can lead to:

- Overheating at Connection Points: A loose or corroded connection creates higher electrical resistance, generating heat that can become a serious fire risk.

- Voltage Drops: Inefficient power transfer leads to performance issues and wasted energy—a major concern for any energy management solution in Dubai.

- Complete System Failure: Thermal expansion and contraction, common in the UAE's climate, can cause weak connections to fail, resulting in costly, production-halting shutdowns.

This guide is your practical framework for selecting the right electrical components UAE suppliers offer. We will cover materials suited for the demanding GCC environment, break down common lug designs, and provide actionable advice for making the correct choice every time.

Understanding Core Cable Lug Materials

The performance of an electrical connection in demanding climates like the UAE and KSA boils down to the lug's material. The choice impacts conductivity, corrosion resistance, and mechanical strength. Understanding the properties of each material helps engineers and panel builders match the component to the application, whether for a control panel in Dubai or heavy industrial machinery in Abu Dhabi.

Copper: The Gold Standard for Conductivity

Copper is the preferred material for cable lugs due to its superior electrical conductivity. This property minimizes power loss and heat buildup at the connection point, which is vital in high-current applications where overheating can lead to failure.

Naturally resistant to corrosion, copper is a reliable choice for the tough climates across the GCC. It's no surprise that copper dominates the cable lug market in the UAE, accounting for nearly 50% of all lugs used. For more details on market drivers, see the global cable lugs market on Maximize Market Research.

For an extra layer of defense, particularly in coastal areas with high salinity like Jebel Ali, tinned copper lugs are the optimal solution. A thin layer of tin plating acts as a shield, preventing oxidation and guaranteeing a solid, low-resistance connection that complies with local utility standards.

Expert Insight: Always specify tinned copper lugs for environments with high humidity or exposure to corrosive elements. The slight additional cost is a wise investment in the long-term integrity and safety of your electrical system, aligning with IEC standards for durability.

Aluminium: The Lightweight and Cost-Effective Choice

Aluminium offers significant weight and cost advantages over copper, making it a common choice for large-scale power transmission cables. An aluminium conductor can be up to 50% lighter than a copper equivalent with the same resistance, easing structural loads and simplifying installation.

However, aluminium instantly forms an insulating oxide layer upon exposure to air, which increases electrical resistance. To ensure a secure connection, follow these best practices:

- Use an antioxidant compound: Before crimping, apply a specialized jointing compound to break down the oxide layer and seal the connection from air and moisture.

- Prep the surface properly: Vigorously wire-brush the conductor immediately before termination to remove any existing oxidation.

Skipping these steps is a common installation mistake that leads to high-resistance connections, overheating, and eventual failure.

Bimetallic Lugs: The Essential Problem-Solver

A fundamental rule in electrical work is to never connect an aluminium conductor directly to a copper terminal. Doing so creates a galvanic cell, which, in the presence of moisture, leads to rapid corrosion and connection failure.

This is where bimetallic lugs become indispensable. These specialized electrical components UAE distributors provide are engineered to safely join aluminium cables to copper busbars. They are manufactured using a friction welding process that molecularly bonds a high-conductivity aluminium barrel to a copper palm. This design prevents direct contact between the dissimilar metals, eliminating the risk of galvanic corrosion and ensuring compliance with safety regulations.

A Practical Guide to Common Cable Lug Types

After selecting the material, the next step is choosing the correct lug shape. Each of the various cable lugs types is designed for a specific termination point. Using the wrong type can lead to a weak mechanical bond and a potential point of failure—a serious risk given the thermal stress common in the UAE climate. Let's break down the most common designs to help you match the right lug to the right task for projects in Dubai, Abu Dhabi, and across the GCC.

Ring and Fork Lugs for Secure Screw Terminals

Ring and fork lugs are the workhorses for control panels and general electrical wiring.

-

Ring Lugs: Their closed-loop design completely encircles the terminal screw. This makes them incredibly secure, as the lug cannot slip out even if vibrations loosen the screw—a critical feature for industrial machinery and high-vibration environments.

-

Fork Lugs (or Spade Lugs): Featuring a U-shaped opening, these allow for faster installation as the terminal screw only needs to be loosened, not fully removed. This time-saving benefit makes them a favorite among panel builders working in tight spaces.

Pin and Blade Lugs for Modern Connections

Pin and blade lugs are designed for newer insertion or clamp-style terminal blocks that do not use traditional screws.

-

Pin Lugs: These terminate the frayed ends of a conductor into a solid, round pin, ideal for plugging into screwless terminal blocks. This neatly contains all strands, preventing stray wires from causing a short circuit.

-

Blade Lugs: Similar to pin lugs, these shape conductor strands into a flat, blade-like terminal for quick, push-in connections often found in European-style terminal blocks and certain automation setups.

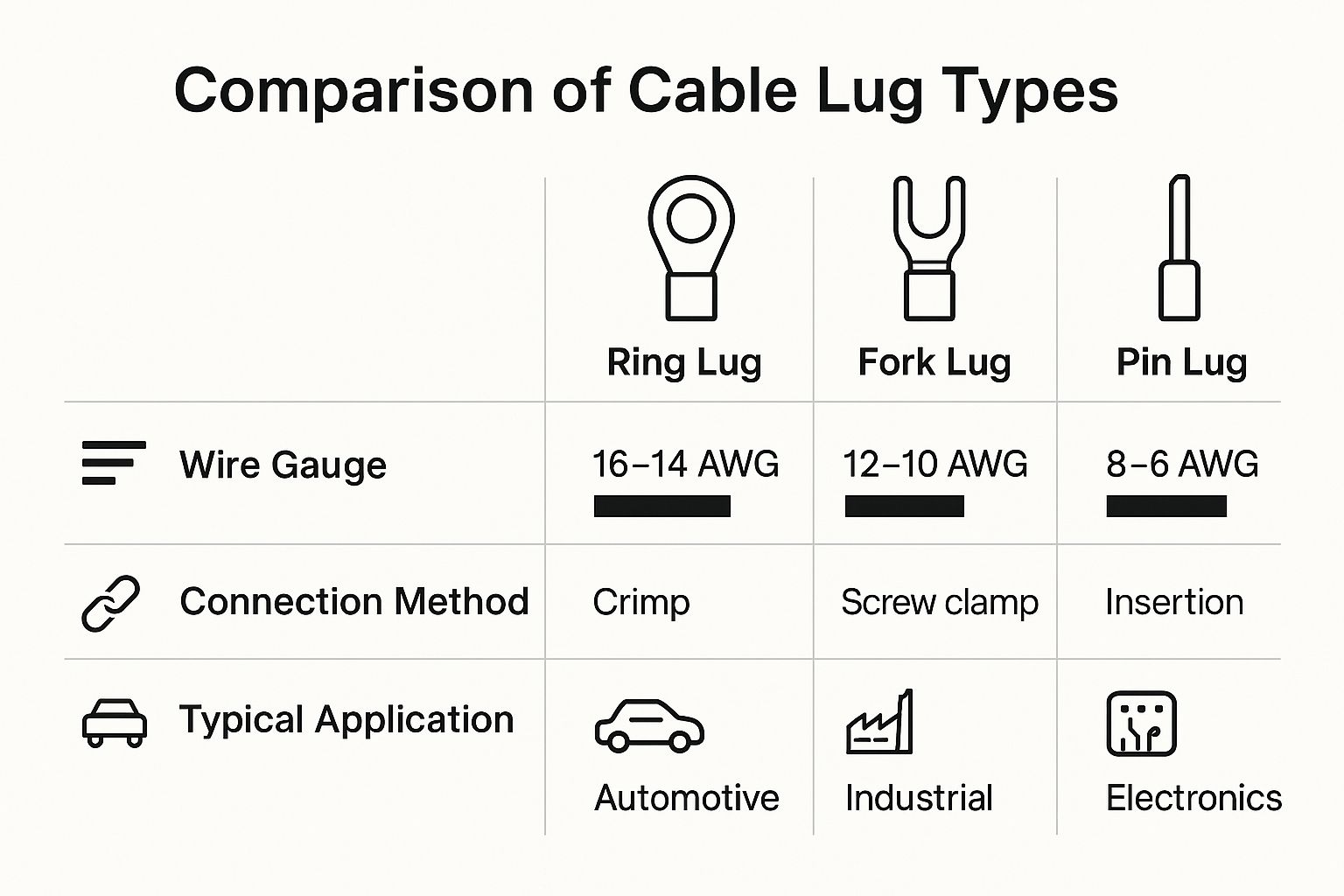

This visual illustrates the key differences between these common lug types.

Comparing Common Cable Lug Types and Applications

This table provides a quick comparison to aid selection for projects in the GCC region.

| Lug Type | Primary Application | Key Advantage | Best For (UAE/GCC Context) |

|---|---|---|---|

| Ring Lug | Securing to a screw or stud terminal | Maximum security; cannot slip off if screw loosens. | Critical connections, high-vibration environments (e.g., HVAC, industrial machinery). |

| Fork/Spade Lug | Multi-point terminal blocks | Fast installation without fully removing the screw. | High-density control panels, wiring harnesses where installation speed is key. |

| Pin Lug | Screwless or push-in terminal blocks | Prevents stray strands for a clean, safe connection. | PLC wiring, modern control systems, fine-stranded conductors. |

| Long Barrel Lug | High-current, large-gauge cables | Superior mechanical strength from double crimping. | Main power feeds, motors, generators, heavy-duty industrial equipment. |

Long Barrel Lugs for Heavy-Duty Applications

For high-current applications involving thick-gauge cables, long barrel lugs are the industry standard. Their extended barrel allows for two or more crimps.

This double-crimping technique provides superior mechanical strength and a larger electrical contact surface area. The result is a highly durable, low-resistance connection capable of withstanding significant vibration and physical stress, making them essential for motors, generators, and main power feeds. For any serious energy management solution in Dubai, using long barrel lugs on primary connections is a best practice.

Butt Splices and C-Taps for Joining and Branching

Not all lugs terminate a connection; some are designed to connect cables.

-

Butt Splices: These hollow tubes are used to join two cables of the same size end-to-end, ideal for repairing a damaged section or extending a wire run.

-

C-Taps: Shaped like the letter 'C', these connectors allow a new branch conductor to be "tapped" onto a main line without cutting it, a common technique in power distribution grids.

How to Select the Perfect Cable Lug

Selecting the right cable lug requires a methodical approach to ensure every connection is robust, efficient, and compliant with local UAE standards. This proactive mindset helps seasoned professionals prevent connection failures before they occur.

The Essential Selection Checklist

Use this practical checklist to ensure your connection will perform reliably in the high-heat, high-humidity environments across the GCC.

- Cable Size (mm² or AWG): The lug's barrel must perfectly match the conductor's cross-sectional area for a proper crimp and optimal electrical contact.

- Material Compatibility: Match materials—copper lugs for copper cables, aluminium for aluminium. When connecting an aluminium cable to a copper terminal, a bimetallic lug is the only safe and compliant choice.

- Stud Hole Diameter: The hole in the lug's palm must precisely match the terminal screw or stud. An oversized hole creates a loose connection, leading to high resistance and dangerous hotspots.

- Voltage and Current Rating: The lug must be rated for the system's maximum voltage and current. In high-current industrial settings in Dubai, this often requires heavy-duty or long barrel cable lugs types.

Environmental and Application-Specific Factors

The unique operating environment in the UAE and wider GCC demands attention to additional details.

A secure termination is the foundation of a reliable electrical system. In the GCC's climate, selecting a lug with the right material plating (IP rating) and temperature rating isn't a recommendation—it's a requirement for preventing premature failure and ensuring operational safety.

Temperature Rating

Given the extreme ambient temperatures in the UAE, every lug must have a maximum operating temperature well above the highest anticipated system temperature. Exceeding this limit will cause the connection to degrade. For high-power electrical components in UAE, verifying the temperature rating is a critical safety check.

Corrosion Resistance

For projects near the coast or in areas with high humidity, corrosion is a primary concern. Tinned copper lugs provide the necessary protection. The tin layer acts as a sacrificial barrier against oxidation, ensuring a stable, low-resistance connection. This is a mandatory specification for outdoor installations or panels exposed to the elements.

Ready to find the right fit? Explore our range of corrosion-resistant solutions by browsing the GoSwitchgear electrical components catalogue.

Mastering Cable Lug Installation and Crimping

Selecting the correct component from the various cable lugs types is only the first step. Proper installation, requiring the right tools and technique, is essential to create a connection that is both mechanically strong and electrically sound in the demanding UAE environment.

The crimp is a cold-weld process that permanently deforms the lug’s barrel, fusing it to the conductor strands. A correct crimp creates a seamless, low-resistance path, ensuring safety and efficiency in any switchgear assembly.

The Crimping Process Step-by-Step

A methodical installation process is key to avoiding bad connections, which can lead to dangerous hotspots or system failure.

-

Precise Cable Stripping: Strip just enough insulation for the conductor to fit fully into the lug's barrel. Exposed copper between the lug and insulation is a short-circuit risk, while insulation trapped in the barrel will result in a weak crimp.

-

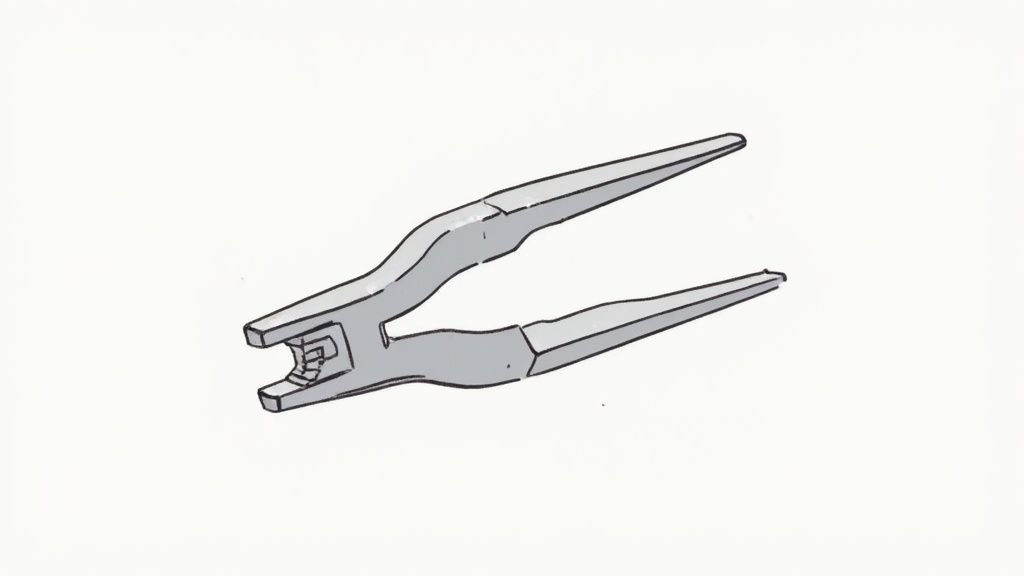

Select the Correct Tool and Die: Always use a professional-grade crimping tool with a die set that matches the specific lug and cable size. Using incorrect tools, such as pliers, guarantees a poor and non-compliant connection.

-

Perform the Crimp: For long barrel lugs, common in heavy-duty applications in Dubai, perform two crimps. Start with the crimp closer to the palm, followed by the second one. This ensures even compaction of the conductor strands.

Good Crimp vs. Bad Crimp: What to Look For

A good crimp will show a clean, clear indentation from the die with no sharp edges or cracked metal. The lug and cable should feel like a single, solid piece.

A common installation mistake is under-crimping or over-crimping. Under-crimping leaves gaps that increase resistance and generate heat. Over-crimping weakens the lug's structure, making it brittle and prone to failure under mechanical stress or vibration.

Growing emphasis on electrical safety and the expansion of renewable energy and industrial automation in the UAE are driving demand for better installation practices. Manufacturers are increasingly offering custom solutions to meet these specific regional needs. You can learn more about these developments from regional cable lugs market trends on imarcgroup.com.

Maintenance Best Practices

For aluminium connections, it is critical to apply an antioxidant compound inside the lug barrel before crimping. This paste breaks down the insulating oxide layer and seals the connection from air and moisture, preventing corrosion. Periodic thermographic inspections of critical systems can identify potential hotspots before they become failures, a practice GoSwitchgear supports to ensure operational excellence and safety.

The Future of Electrical Connections in the GCC

The market for high-performance electrical components in the UAE and the wider GCC is expanding rapidly, driven by ambitious infrastructure projects, renewable energy initiatives, and industrial growth. This creates a significant demand for reliable connectivity, where advanced cable lugs types play a critical role.

Evolving Standards and Smart Technologies

Regional standards are continuously updated to meet modern demands for greater energy efficiency and resilience. This directly impacts component specifications, requiring lugs that can withstand higher temperatures and resist corrosion in harsh environments like solar farms or the complex networks of Dubai's smart city projects.

The future belongs to components that support smarter grids, integrate with automated systems, and provide reliable service for decades.

The Middle East cable lugs market is projected to reach an estimated $574.86 million by 2025, with the UAE holding 11.66% of that market, highlighting the importance of quality electrical connections to its construction and energy sectors. You can explore these projections further in the regional cable lugs market growth on Cognitive Market Research.

Understanding these trends positions GoSwitchgear not just as a supplier, but as a strategic partner ready to help clients in Dubai and Abu Dhabi meet the demands of tomorrow's projects.

Cable Lugs: Your Questions Answered

Here are answers to common questions from engineers and electricians in the field.

What Is the Difference Between a Mechanical and a Compression Lug?

A compression lug (or crimp lug) creates a permanent connection using a specialized tool that deforms the lug's barrel onto the cable. This results in a highly reliable, low-resistance bond. A mechanical lug uses a screw or bolt to clamp the conductor, allowing for installation with standard tools and potential disassembly. For permanent installations in the UAE, compression lugs are the superior choice for their strength and electrical integrity.

Why Is Tin Plating Important for Copper Lugs in the UAE?

Tin plating is essential for corrosion resistance in the UAE's high-humidity and saline coastal environments. Bare copper oxidizes when exposed to these conditions, and this oxide layer increases electrical resistance, which generates heat and can lead to connection failure. The tin layer acts as a protective shield, ensuring a durable, low-resistance connection and enhancing long-term safety.

Can I Use a Copper Lug on an Aluminium Cable?

No. Directly connecting a standard copper lug to an aluminium cable is a critical safety violation. The contact between these dissimilar metals causes galvanic corrosion, which rapidly degrades the connection, making it unreliable and a serious fire hazard. To connect an aluminium cable to a copper terminal, you must use a bimetallic lug, which is specifically designed with an aluminium barrel and a copper palm to prevent this corrosive reaction and ensure a safe, lasting termination.

To discuss your project requirements with our technical team in Dubai, contact us for expert support and a tailored quote.

Leave a Reply