Streamline Your Panel Building: A Guide to Push-In Terminal Blocks for UAE & GCC Projects

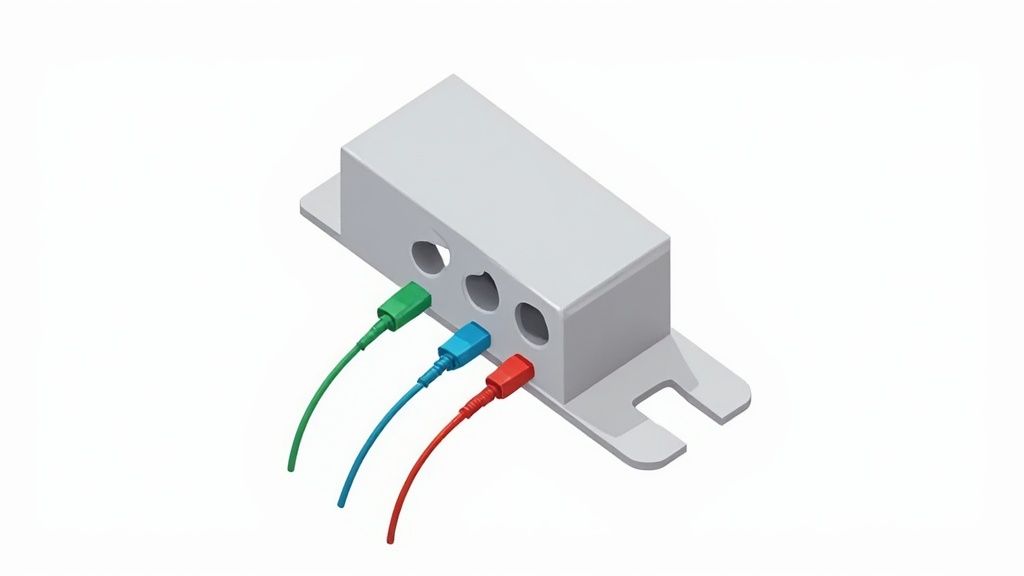

For engineers and panel builders across the UAE, wiring a complex control panel with the ease of plugging in a headphone jack is no longer a futuristic concept. The push-in terminal block makes this a reality, offering a secure, tool-free connection for solid wires and ferruled conductors that drastically reduces installation time and enhances system reliability in demanding GCC climates.

Understanding Push-In Technology and Its Local Advantage

At its core, push-in technology utilises a pre-loaded internal spring clamp. This mechanism acts as a 'smart grip,' ready to accept a wire. When a solid or ferruled stranded wire is inserted, it bypasses a small gate, and the spring clamp immediately secures it with a firm, consistent hold. This pre-set pressure eliminates the guesswork common with screw terminals, where over-tightening can damage conductors and under-tightening creates hazardous loose connections.

Why This Mechanism Excels in the GCC Climate

In the demanding environmental conditions of the UAE and wider GCC—characterised by extreme heat, humidity, and dust—this level of reliability is a critical safety feature. The constant pressure from the spring clamp ensures a gas-tight, secure connection that effectively mitigates issues arising from:

- Vibration: In industrial settings with heavy machinery, constant vibrations can loosen screw connections over time, leading to intermittent faults or complete system failure. Push-in technology maintains a steadfast grip.

- Thermal Cycling: The significant temperature fluctuations common in the UAE cause materials to expand and contract. The spring mechanism automatically compensates for these changes, maintaining consistent contact pressure and preventing connection degradation.

This inherent stability is crucial for preventing loose connections, a primary cause of overheating and potential electrical fires. We're observing a significant trend towards more reliable electrical components in the UAE. The regional terminal block market, valued at US$ 223.66 million in 2022, is projected to reach US$ 276.39 million by 2028, reflecting the growing demand for advanced components in the region's expanding industrial and infrastructure projects. You can explore this trend further in this detailed market analysis.

Ultimately, the elegant and effective design of a push-in terminal block translates to enhanced speed, safety, and reliability. For the large-scale projects underway in Dubai, Abu Dhabi, and across Saudi Arabia, these benefits lead to faster project completion and reduced long-term maintenance, setting a new standard for modern panel building.

Comparing Push-In vs. Screw and Spring Cage Terminals

For any panel builder or procurement team in the GCC, selecting the right terminal block is a critical decision impacting project timelines, labour costs, and long-term system integrity. While traditional screw and spring cage terminals have been staples, the push-in terminal block now offers compelling advantages specifically suited to the region's challenging industrial environments.

This shift is part of a global movement. The international terminal block market was valued at US$ 4.78 billion in 2023 and is forecasted to hit US$ 7.12 billion by 2031, driven by industrial automation and renewable energy sectors where connection speed and reliability are paramount. Push-in technology is a key contributor to this growth, especially for major electrical projects across the UAE and KSA.

Terminal Block Technology Comparison

Let's break down how these technologies compare. While each has its application, the performance differences become critical in modern, high-stakes projects.

| Feature | Push In Terminal Block | Screw Terminal Block | Spring Cage Terminal Block |

|---|---|---|---|

| Wiring Speed | Fastest; tool-free for solid/ferruled wires | Slowest; requires screwdriver for each connection | Faster than screw; requires tool to open clamp |

| Vibration Resistance | Excellent; constant spring pressure maintains contact | Poor; screws can loosen over time, requiring re-tightening | Good; spring mechanism holds wire securely |

| Reliability | Very high; gas-tight, maintenance-free connection | Moderate; depends on correct torque and regular checks | High; reliable connection under vibration |

| Labor Cost | Lowest; reduces installation time by up to 50% | Highest; time-intensive, requires skilled torqueing | Moderate; faster than screw but still requires tool handling |

| Ease of Use | Easiest; intuitive push-to-connect action | Most complex; requires proper tool use and torque settings | Easy; tool-assisted insertion and removal |

While screw terminals are familiar, both push-in and spring cage designs offer superior reliability and speed, with push-in leading in overall efficiency.

Installation Speed and Efficiency

The most immediate benefit of push-in terminals is the remarkable speed. Wiring a panel with screw terminals involves a technician repeatedly using a screwdriver to tighten each connection to a specific torque—a slow process prone to human error.

Spring cage terminals improved on this by requiring a tool to open the clamp for wire insertion. Push-in terminals, however, are in a class of their own. For solid or ferruled stranded wires, the connection is entirely tool-free. This simple change can reduce wiring time by up to 50% compared to screw terminals. On a large-scale project in Dubai, where labour is a significant operational expense, these time savings translate directly into cost savings.

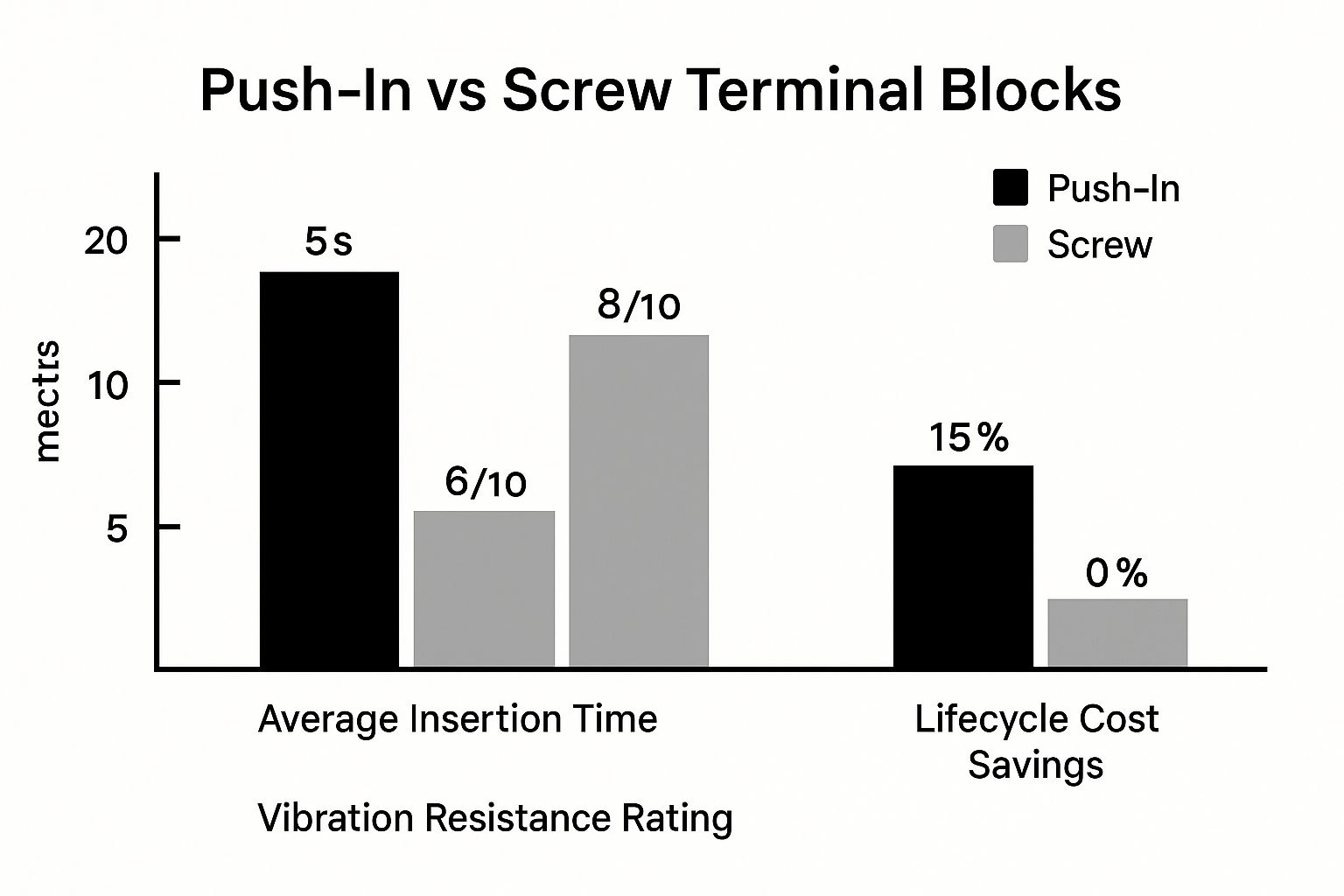

This infographic highlights the performance gap between push-in technology and traditional screw terminals.

The data is clear. In terms of speed and vibration resistance, push-in technology provides tangible long-term value.

Reliability Under Vibration and Thermal Stress

In the industrial hubs of the GCC, from manufacturing plants in Dubai to major infrastructure projects in KSA, vibration is a constant threat to electrical connections. Screw terminals are particularly vulnerable, as mechanical shaking and thermal cycling can cause them to loosen over time. This necessitates periodic maintenance for re-tightening, consuming resources and introducing potential points of failure.

The core strength of the push-in terminal block lies in its internal spring mechanism. It exerts constant, dynamic pressure on the conductor, automatically adjusting for wire settlement or temperature-induced changes. This creates a maintenance-free, gas-tight connection that remains secure throughout its operational life.

This inherent resilience makes push-in terminals the superior choice for applications involving motors, conveyors, or other heavy machinery. For more specifics on different connection types, our complete terminal blocks selection guide is an excellent resource for your next project.

Real-World Benefits for GCC Panel Builders

For panel builders in the GCC, the true value of a component is measured by its impact on project outcomes. The adoption of a push-in terminal block delivers tangible benefits that positively affect labour costs, project schedules, and operational safety.

The most significant advantage for electricians and technicians is the dramatic increase in wiring speed. By eliminating the need for a screwdriver for most connections, installation time can be reduced by up to 50% compared to traditional screw terminals. On a major project in Dubai or Abu Dhabi, this translates to fewer man-hours, reduced costs, and accelerated project completion.

Enhanced Safety in High-Temperature Environments

In the challenging climate of the UAE, secure electrical connections are non-negotiable. The consistent clamping force of a push-in terminal block is critical. Screw terminals can loosen due to thermal cycling, creating high-resistance points that lead to overheating. The internal spring, however, maintains constant pressure, preventing such failures.

This built-in reliability makes push-in terminals a safer choice for control panels operating in high-temperature environments and aligns with modern quality assurance processes, crucial for meeting the stringent standards of industrial projects in the region.

Superior Performance Under Vibration

Across the GCC, from bustling industrial zones to critical infrastructure, equipment vibration is a common challenge that compromises screw-based connections.

A push-in terminal block is engineered for these conditions. Its pre-loaded spring creates a gas-tight, vibration-proof connection that remains secure. This ensures that motors, conveyors, and other heavy machinery operate reliably without the need for periodic re-tightening of terminals.

This robust reliability is essential for building control panels that can withstand demanding operational environments. Pairing these dependable terminals with precise monitoring components like the Nippen DT-108 RS multifunction meter creates a truly resilient system. Switching to push-in technology allows you to build faster, safer, and more durable control systems tailored for the region’s unique challenges.

How to Properly Wire a Push-In Terminal Block

A reliable connection depends on correct installation. For electricians and panel builders on projects across the UAE, mastering the wiring process for a push-in terminal block ensures every connection is secure and durable. The process is straightforward, but success hinges on proper wire preparation.

The first and most critical step is preparing the conductor to create a clean, solid point of contact for the internal spring mechanism. The preparation method varies slightly for solid and stranded wires.

Preparing the Conductor for a Flawless Connection

With solid conductors, the process is simple. Strip the insulation to the correct length—typically between 8 mm and 10 mm. Quality terminal blocks, like those from GoSwitchgear, often have a strip length guide printed on the housing. Using a dedicated wire stripping tool ensures a clean cut without nicking the copper conductor.

For stranded conductors, using a ferrule is highly recommended for any professional installation in Dubai or elsewhere in the GCC.

A ferrule is a small metal tube crimped onto the end of a stranded wire. It bundles the fine strands together, preventing fraying and ensuring all strands are captured by the terminal clamp. This creates a solid connection point, improves conductivity, and eliminates the risk of stray strands causing short circuits.

Using a ferrule also makes wiring stranded conductors a tool-free process, just like with solid wires.

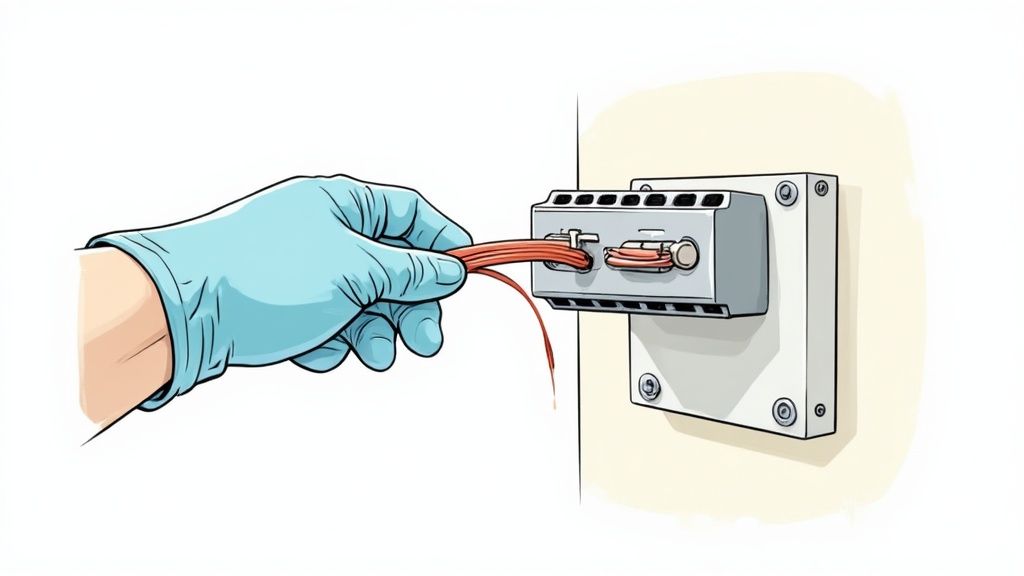

Step-by-Step Insertion and Removal Process

Once the wire is prepared, making the connection is exceptionally fast—a significant advantage in large-scale electrical installations.

- Prep the Wire: Strip insulation to the manufacturer's specified length. For stranded wire, crimp on an appropriately sized ferrule.

- Insert the Conductor: Push the prepared solid wire or ferruled stranded wire directly into the terminal's insertion point until it stops. A subtle "click" often confirms the spring clamp has engaged.

- Verify the Connection: Gently tug the wire to confirm it is secure. A firm connection is ready for the demanding conditions of the GCC.

Removing a wire for maintenance or modification is equally simple:

- Engage the Actuator: Locate the small push-button or actuator slot, often coloured orange for high visibility.

- Insert a Tool: Press a small flat-head screwdriver or a dedicated release tool into the actuator slot to compress the spring and open the clamp.

- Remove the Wire: While keeping the actuator depressed, gently pull the wire out.

Following these steps helps electricians avoid common errors like partial insertions or improper wire preparation, ensuring every termination is safe and reliable.

Selecting the Right Push In Terminal Block

Choosing the correct component is fundamental to any reliable electrical system. For engineers and procurement managers in the UAE, selecting the ideal push in terminal block is a strategic decision that must balance technical specifications with the region's harsh environmental realities. The right choice ensures control panels perform flawlessly, whether in a Dubai skyscraper or a Saudi industrial facility.

The initial step is to match the terminal block's core electrical ratings with the application's demands to prevent component failure and ensure safety.

Core Electrical and Mechanical Specifications

Verifying that the component’s ratings align with your system’s requirements is a critical step for both safety and regulatory compliance.

- Voltage and Current Ratings: Ensure the block's nominal voltage and current ratings (e.g., 600V, 20A) are comfortably above your circuit's maximum operating values to provide a necessary safety margin.

- Wire Gauge Compatibility: Check the accepted wire size range (AWG and mm²). A block rated for 22-12 AWG will not securely connect a wire outside this range.

- Certifications: For projects in the GCC, look for essential approvals like IEC (International Electrotechnical Commission) and UL. These certifications guarantee the product meets stringent international safety and performance standards.

Environmental Resilience for the GCC Climate

Beyond electrical ratings, the terminal block must withstand the local climate. The intense heat, humidity, and dust common across the UAE require components built for durability.

A key specification is the IP rating (Ingress Protection), which indicates its sealing effectiveness against solids (first digit) and liquids (second digit). For dusty industrial environments, an IP6x rating is often necessary. Equally important is the operating temperature range. A component rated up to 100°C ensures it will not degrade or fail during peak summer heat.

In the GCC, a terminal block’s ability to resist environmental stress is just as crucial as its electrical ratings for ensuring long-term operational reliability and safety.

Matching the Type to the Application

Different push-in terminal block designs are optimised for specific functions. Selecting the appropriate type simplifies wiring and enhances system functionality.

Common types include:

- Multi-Level Blocks: These space-saving designs stack two or three connection levels, ideal for crowded DIN rails.

- Sensor/Actuator Blocks: Purpose-built for 3- or 4-wire sensors and actuators, often featuring LED indicators for status feedback.

- Disconnect Blocks: Essential for maintenance and testing, these blocks include a built-in lever or knife-switch to safely isolate a circuit without disconnecting wires.

By systematically evaluating these factors, you can confidently select a push in terminal block that delivers superior performance, safety, and durability. For more guidance, our article on choosing a terminal block offers additional insights.

Key Applications in the UAE Industrial Landscape

The true value of a push-in terminal block becomes evident in its application across critical industries in the UAE and the wider GCC. It is a practical solution that addresses the unique challenges of local projects, from urban developments to remote industrial sites.

In Dubai's iconic skyscrapers and large commercial complexes, control panel space is at a premium. Push-in technology enables high-density wiring, allowing panel builders to fit more functionality into smaller enclosures while maintaining safety and accessibility. The speed of tool-free connections also helps keep large-scale construction projects on schedule.

Powering Industrial and Renewable Energy Growth

In Saudi Arabia's expanding manufacturing sector, machinery operates under constant stress. The superior vibration resistance of a push-in terminal block is essential here. It ensures automated systems and heavy equipment run without interruptions from loose connections, improving productivity and reducing maintenance downtime.

For renewable energy projects, such as the vast solar farms in the UAE's desert environments, reliability is paramount. The secure, gas-tight connections of push-in terminals are vital for long-term performance, withstanding extreme temperature fluctuations to ensure a consistent power supply to the grid.

Across these diverse applications, the core benefits remain consistent.

Whether saving space in a high-rise, securing a connection on a factory floor, or guaranteeing performance in a solar field, GoSwitchgear provides proven solutions tailored for the region. Every push-in terminal block we supply is engineered to meet the high standards of the most ambitious projects in the UAE and GCC.

Common Questions About Push In Terminal Blocks

As engineers and electricians across the UAE consider adopting new components, practical questions arise. Here are answers to common queries about making the switch to the push in terminal block.

Are Push In Connections as Reliable as Screw Terminals?

Yes, and in many applications, they are more reliable. A screw can loosen over time due to vibration or thermal cycling. In contrast, a push-in terminal’s internal spring applies constant, engineered force on the wire. This creates a gas-tight connection that maintains its integrity over time, offering superior long-term performance without the need for periodic re-tightening.

Do I Need Special Tools to Wire Them?

No special tools are required for insertion. For solid wires or stranded wires fitted with ferrules, you simply push the wire directly into the terminal. To release a wire, a small, standard screwdriver or a dedicated release tool is all that is needed to press the actuator.

Can I Use Stranded Wires Without a Ferrule?

While some designs permit this by first pressing the actuator to open the clamp, using a ferrule is the recommended best practice. A ferrule bundles the fine strands, preventing fraying and ensuring a complete, solid insertion for maximum conductivity and connection reliability.

How Do They Perform in the High Heat of the GCC?

They are designed for it. High-quality push-in terminals are engineered for harsh environments. The housing is typically made from high-grade polyamide that withstands high ambient temperatures. Critically, the constant spring pressure prevents connections from loosening due to thermal cycling—a common failure point in screw terminals that can lead to increased resistance and overheating. This makes them a safer and more reliable choice for the demanding climate in the UAE.

For reliable, high-performance electrical components engineered for the GCC's unique challenges, explore the extensive catalogue at GoSwitchgear. Our team in Dubai is ready to support your next project.

Find the right push-in terminal block for your project at GoSwitchgear

Leave a Reply