A Guide to Residual Current Device Testing in the UAE

Ensuring a residual current device (RCD) functions correctly is non-negotiable for engineers, electricians, and panel builders across the UAE. For this critical life-saving component, testing is the only way to certify it will perform during an electrical fault. This procedure confirms the device will trip within required safety timeframes, protecting personnel and assets from serious harm.

Why RCD Testing Is Critical in the UAE and GCC

A Residual Current Device (RCD) is the primary defence against electrocution and electrical fires. However, its effectiveness is not guaranteed without regular, professional checks. This is especially true in the demanding environmental conditions seen across the UAE and the wider GCC region, where performance degradation is a significant risk.

Environmental Stress on Electrical Components

The climate in the GCC is tough on equipment. Harsh conditions in Dubai, Abu Dhabi, and across Saudi Arabia create unique challenges for sensitive electrical components like RCDs. These factors can degrade an RCD's performance over time, turning a reliable safety switch into a latent failure point.

Key environmental stressors include:

- Extreme Heat: High ambient temperatures can accelerate the aging of internal mechanics and sensitive electronics within an RCD, leading to premature failure.

- High Humidity: Moisture ingress is a major concern, leading to corrosion on critical connections and tripping mechanisms. This can cause the device to seize or respond too slowly.

- Pervasive Dust: Fine, airborne dust common in the region can penetrate an RCD's housing, obstructing moving parts and preventing the device from tripping correctly during a fault.

A functional RCD is more than a component; it's an assurance. In the GCC's climate, assuming it works without verification is a significant risk to project safety and compliance. Regular residual current device testing turns that assumption into a certainty.

Regulatory and Compliance Mandates

Beyond best practices, rigorous testing is a legal and regulatory requirement. Authorities like the Dubai Electricity and Water Authority (DEWA) enforce strict compliance with international safety standards to ensure every electrical installation is safe. For professionals in the field, this means testing is essential for project sign-offs and operational certification.

Compliance with standards such as IEC 61008 and IEC 61009 is mandatory. These standards focus heavily on trip time verification. For example, a standard 30mA RCD must disconnect the circuit within 300 milliseconds to pass inspection—a critical parameter verifiable only through proper testing. A deep understanding of RCD testing is a fundamental skill for any technician responsible for delivering a safe energy management solution in Dubai.

Preparing for a Safe and Compliant RCD Test

Before connecting any test instrument, a systematic preparation routine is non-negotiable for residual current device testing. This process guarantees operator safety and accurate, compliant results, which is vital for commercial and industrial sites across the UAE.

A successful test begins with a thorough visual inspection of the RCD and its enclosure. Look for obvious defects like cracks in the casing, loose connections, or any signs of physical compromise.

In the GCC, with our unique climate challenges, vigilance is key. Pay close attention to signs of corrosion on terminals or overheating, such as discoloration on the housing. These seemingly minor issues can prevent an RCD from tripping when it matters most.

Essential Equipment and Safety Protocols

After the visual check, gather your tools and implement safety procedures. Using properly calibrated and certified equipment is essential for obtaining trustworthy results that meet local standards.

Your essential toolkit should include:

- A calibrated Residual Current Device (RCD) Tester compliant with relevant IEC standards.

- Appropriate Personal Protective Equipment (PPE), including insulated gloves and safety glasses.

- Lockout/tagout (LOTO) devices to ensure the circuit remains de-energized.

- Clear warning signs to secure the area and notify personnel of ongoing testing.

Safety is a mindset, not just a checklist. Always verify that a circuit is de-energized before making contact. This "test-before-you-touch" protocol prevents serious accidents and is the hallmark of a true professional.

Isolating the Circuit Correctly

Proper isolation is the foundation of safe electrical testing. You must not connect your RCD tester until the circuit is completely de-energized. This involves opening the correct circuit breaker and applying a lockout device to prevent accidental re-energization.

With the circuit locked out, use a voltage tester to confirm zero potential at the RCD terminals. This quick check protects you from electric shock and prevents damage to expensive test equipment. This safety-first approach creates a controlled environment for obtaining the accurate, compliant residual current device testing results you need.

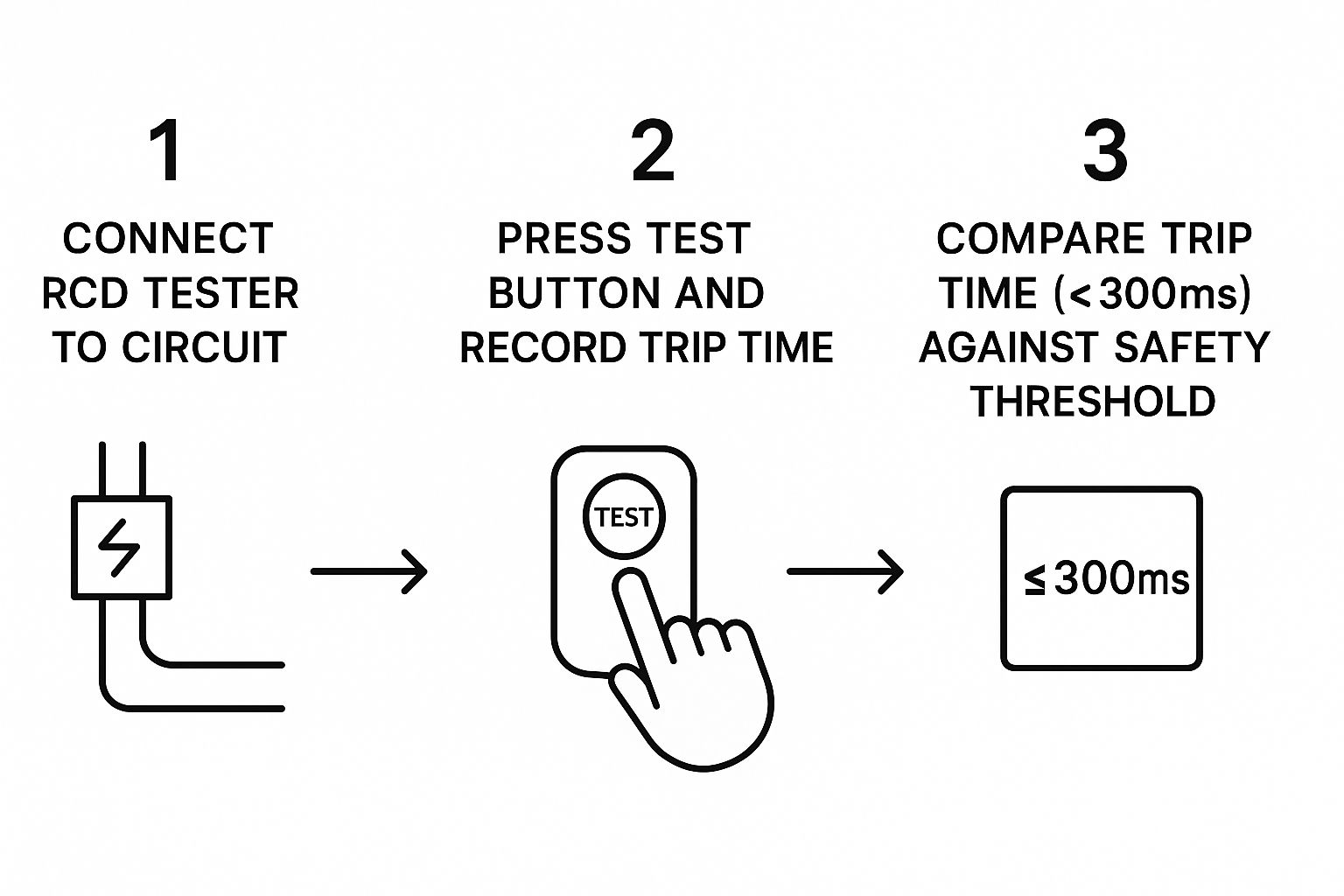

How to Perform an RCD Trip Time Test

With safety checks complete, the next step is performing the residual current device testing itself. This goes beyond the simple push-button test; the goal is to verify the RCD's actual trip time—a critical metric that confirms its ability to protect people and equipment.

The first step is to connect the RCD tester correctly. The leads are connected to the phase, neutral, and earth terminals of the circuit, typically at a socket outlet downstream from the RCD. This setup allows the tester to safely inject a precise fault current, simulating a real earth leakage event.

Selecting the correct test current is critical. For RCDs providing personnel protection in commercial and industrial sites across Dubai, the standard test current is 30mA. This value, labelled IΔn on the device, is the rated residual operating current that should initiate a trip.

Executing the Phase Angle Tests

A comprehensive test requires initiating the fault current at both the 0° and 180° phase angles of the AC sine wave. This is necessary because an RCD's internal mechanism can respond differently depending on where the fault occurs on the wave.

I have seen devices pass at 0° but fail at 180°, indicating a hidden defect that a single test would miss—a risk not worth taking on any project.

This connect, test, and validate process ensures the RCD performs against the safety benchmark. For a standard 30mA device, the trip time must be under 300 milliseconds.

Testing at Different Current Multiples

To assess the RCD's overall health, the trip time test must be conducted at several current levels. Each test provides unique insights into the device's condition.

- Test at 0.5x IΔn (15mA): At half the rated current, the RCD should not trip. This verifies it is not over-sensitive, which could cause nuisance tripping and operational disruptions.

- Test at 1x IΔn (30mA): This is the primary compliance test. The RCD must trip within the time specified by IEC standards, typically less than 300ms.

- Test at 5x IΔn (150mA): At five times the rated current, the RCD must react rapidly, usually in under 40ms. This test confirms its ability to respond quickly to a major fault.

While this data is invaluable, a complete system health assessment may require further analysis with a quality power quality meter from GoSwitchgear. This can help identify underlying power quality issues that might affect RCD performance.

Interpreting Test Results for DEWA Compliance

Executing the residual current device testing procedure is only half the task. Correctly interpreting the results is what determines if an installation is safe, compliant, and ready for service in demanding environments like Dubai or Abu Dhabi. The trip times measured in milliseconds (ms) are the vital signs of an RCD’s health.

For projects under DEWA's jurisdiction, compliance with international standards like IEC 61008 and IEC 61009 is a mandatory requirement. These standards form the basis of local electrical codes and set the pass/fail benchmarks your test results must meet.

Understanding what these numbers mean empowers you to make correct decisions on-site, whether certifying a new installation, flagging a faulty device, or diagnosing a complex circuit issue.

Decoding Trip Time Results

The trip time is the most critical metric obtained from your tester, indicating how quickly the RCD disconnects power during a fault. A slow reaction can be the difference between a minor incident and a serious electrical shock.

Here is a practical breakdown of what your results indicate:

- No Trip at 0.5x IΔn (e.g., 15mA): This is a PASS. An RCD that remains stable at half its rated sensitivity is functioning correctly, preventing nuisance tripping in busy commercial facilities.

- Trip at 1x IΔn (e.g., 30mA): The trip time must be less than 300ms. This is the primary compliance check. A reading of 280ms passes, while 310ms fails.

- Trip at 5x IΔn (e.g., 150mA): To handle high-current faults, the device must react almost instantly. The standard requires a trip time of less than 40ms. This test confirms the RCD's mechanical components can operate rapidly under stress.

A sluggish trip time, even one slightly over the 300ms limit, is often the first sign of degradation. Dust or internal corrosion, common in the GCC climate, can physically slow the tripping mechanism. This should be treated as a failure requiring immediate device replacement.

Pass or Fail: A Clear Decision Framework

To convert test data into a definitive pass or fail decision, you must consider all test results. For an RCD to be deemed safe and compliant, it must pass every single required test.

Use this framework to make the call on-site:

| Test Condition | Expected Outcome | What It Means for Compliance |

|---|---|---|

| 0.5x IΔn (No Trip) | RCD does not trip. | PASS – Prevents nuisance tripping. |

| 1x IΔn (0° Phase) | RCD trips in < 300ms. | PASS – Meets standard safety time. |

| 1x IΔn (180° Phase) | RCD trips in < 300ms. | PASS – Confirms consistent performance. |

| 5x IΔn | RCD trips in < 40ms. | PASS – Ensures rapid high-fault protection. |

A failure in any of these tests means the RCD is not fit for service. This knowledge provides the authority to either sign off on an installation or justify immediate corrective action, ensuring all electrical components in UAE projects meet strict safety standards.

Troubleshooting Common RCD Testing Failures

An RCD test failure can halt a project, creating a frustrating diagnostic challenge. For technicians in the UAE, identifying the root cause is as important as conducting the test. A failed test does not always indicate a faulty RCD; it can often point to a deeper issue within the circuit.

When an RCD fails, adopt a systematic approach instead of immediately replacing the device. This logical process saves time, reduces costs, and ensures the entire circuit is safe.

Scenario One: RCD Fails to Trip

This is the most dangerous failure mode. When a 1x or 5x IΔn test is performed and the RCD does not trip, it means the device offers zero protection against electric shock. Before condemning the RCD, eliminate other possibilities.

First, verify your test equipment. Ensure test probes have a solid connection and the tester is calibrated and functional. Then, inspect the device itself. A common cause of failure, especially in the dusty and humid GCC climate, is a seized internal mechanism.

- Action Plan:

- Confirm all tester connections are firm and correctly placed.

- Use the RCD's built-in push-button test. If this fails, the internal mechanics are almost certainly defective.

- If the push-button test works but the instrument test fails, there may be an issue with the circuit's earth continuity.

- In nearly all "no trip" scenarios with correct connections, the RCD must be replaced immediately.

A "no-trip" scenario is a non-negotiable failure. The device provides no protection and must be removed from service immediately to prevent a severe safety incident.

Scenario Two: RCD Trips Instantly or at 0.5x IΔn

If the RCD trips at half its rated current (0.5x IΔn) or immediately upon connecting the tester, it indicates a different problem: an existing earth leakage fault in the circuit. In this case, the RCD is working correctly by detecting a pre-existing condition. Your task is to locate the source of the fault.

Use a process of elimination. Start by unplugging all appliances and equipment on the circuit. Retest the RCD. If it passes, the fault lies with one of the disconnected loads.

Next, reconnect each piece of equipment one by one, re-testing after each addition. When the RCD fails again, you have identified the faulty appliance. This diagnostic skill, a key component of advanced electrical safety training, transforms a simple compliance test into a powerful tool for ensuring total circuit integrity.

Need a Partner in Electrical Safety and Compliance?

In the UAE, consistent residual current device testing is fundamental to ensuring personnel safety, maintaining regulatory compliance, and guaranteeing operational continuity. By following a robust testing procedure and knowing how to interpret the results, you ensure every installation is protected from dangerous electrical faults.

For projects in Dubai, Abu Dhabi, or anywhere in the GCC, you need high-quality, certified components that withstand our unique climate.

At GoSwitchgear, we are more than a supplier; we are your local partner. Our team possesses the expertise to guide your procurement decisions, and our portfolio includes the safety-critical solutions your projects demand.

Does your project require uncompromising safety and compliance? Connect with our team in Dubai. We have the electrical components UAE projects need and the technical know-how to help you succeed.

Questions We Hear All the Time About RCD Testing

On-site, several practical questions about residual current device testing consistently arise. For engineers and technicians across the UAE and GCC, clear answers are essential for real-world safety and compliance. Here are some of the most common queries we receive.

How Often Should We Be Testing RCDs?

The built-in push-button should be operated by the user every three to six months as a basic mechanical check. However, a full instrument test by a qualified electrician should be conducted at least annually for most commercial and industrial sites.

For high-risk environments or locations with harsh conditions (e.g., high dust, moisture, or extreme temperatures), more frequent testing may be necessary. Always consult local regulations and site-specific safety plans.

What’s the Real Difference Between Test Types?

The push-button test and a full instrument test are fundamentally different. The push-button test only confirms that the RCD's mechanical switch can physically operate. It provides no information about its trip time or sensitivity—the two most critical safety parameters.

An instrument test is the only method to verify performance. It simulates a real fault and provides quantitative data on trip time and trip current, proving the device operates within the strict safety limits required by IEC standards and local authorities like DEWA.

An RCD that passes a push-button test can still fail a trip-time test. The instrument test is the definitive measure of whether an RCD will provide effective protection against electric shock.

What Do I Do If an RCD Fails the Test?

First, verify your test procedure and ensure your equipment is correctly calibrated. If a re-test confirms the failure, the RCD is considered faulty and unsafe.

The only appropriate action is to have a qualified electrician replace it immediately. Do not attempt to repair the device. Document the failure and replacement in your site safety records to maintain a clear compliance history for your energy management solution in Dubai.

For comprehensive support with high-quality electrical components and expert advice on safety compliance in the UAE, trust GoSwitchgear. Explore our extensive range of products and resources at https://goswitchgear.ae.

Leave a Reply