A Professional’s Guide to Electric Vehicle Charger Installation in the UAE & GCC

Installing an electric vehicle charger in the UAE is a detailed process that demands more than just mounting a unit. For engineers, panel builders, and procurement teams, a successful project hinges on a solid grasp of local electrical codes, the unique challenges of the GCC climate, and the specific power profile of the property. This is what guarantees a safe, compliant, and reliable installation that withstands the region's demanding environment.

Getting Started with EV Charger Installation in the UAE

As electric vehicles become a common sight across the UAE and the wider GCC, the demand for high-calibre electric vehicle charger installation is skyrocketing. For engineers, electricians, and panel builders, this represents a significant growth opportunity.

However, executing these projects in this region is not a simple copy-paste exercise. The unique operational environment demands a specialized approach. This guide serves as a practical roadmap for managing EV charging projects with technical precision, moving beyond generic advice to address the real-world regulatory and climate-related hurdles faced in Dubai, Abu Dhabi, and beyond.

The Core Phases of a Project

A professional installation follows a clear, structured process. Mastering these key stages is critical for consistent, high-quality outcomes.

- Initial Site Assessment: Evaluate the building's existing electrical system to determine its capacity to handle the new load and identify a compliant, practical location for the charger.

- Load Calculation: Accurately calculate if the main distribution board can support the charger without overloading the property’s power supply—a critical step for safety and compliance.

- Equipment Selection: Choose chargers and components with high IP ratings and ambient temperature tolerances. Sourcing from a reliable supplier like GoSwitchgear ensures access to products like DIN rail isolators and SMPS power supplies built for the intense GCC climate.

- Navigating Regulations: Secure all necessary permits and approvals from local authorities, such as DEWA in Dubai or ADDC in Abu Dhabi.

- Installation & Safety: Execute all wiring according to best practices, install correct circuit protection (e.g., Type B RCDs), and perform all mandatory safety checks.

- Commissioning & Handover: Conduct final tests to verify system functionality and hand over all necessary documentation to the client.

Of course, before diving into the technical work, it's essential to have your business structure in order. Understanding the steps for Company Formation in the UAE is a prerequisite for any commercial project, ensuring you're licensed and operating legally from the start.

A common mistake is underestimating how ambient heat affects electrical components. A piece of equipment that works perfectly in a cooler climate can fail prematurely during a Dubai summer if it wasn't specified correctly from the start.

Mastering these steps doesn't just lead to a safe, compliant installation—it builds your reputation for quality in a competitive market. Partnering with a knowledgeable supplier like GoSwitchgear provides access to the technical support and certified electrical components UAE professionals need to handle these complex projects with confidence.

Performing a Proper Site Assessment and Load Calculation

Before a single wire is pulled for an EV charger installation, a meticulous site assessment is non-negotiable. This is the foundation for a safe, compliant, and efficient charging system. Skipping or rushing this phase invariably leads to expensive rework, project delays, and significant safety risks.

For any professional engineer or electrician in the UAE, the first stop is the property's main distribution board (MDB). The primary objective is to determine if the existing electrical infrastructure can handle the continuous, heavy load of an EV charger. This involves much more than a cursory glance at the main breaker.

Evaluating Existing Electrical Infrastructure

First, identify the type of electrical supply. Is it a single-phase system, common in many residential villas in Dubai, or a three-phase system, standard in new developments and commercial towers across Abu Dhabi? This detail dictates the type of charger that can be installed and fundamentally alters the load calculation.

Next, conduct a detailed inventory of all existing circuits, accounting for power-hungry appliances like air conditioning units, water heaters, and electric cooktops. In the GCC's climate, HVAC systems represent a massive, often constant load that cannot be underestimated.

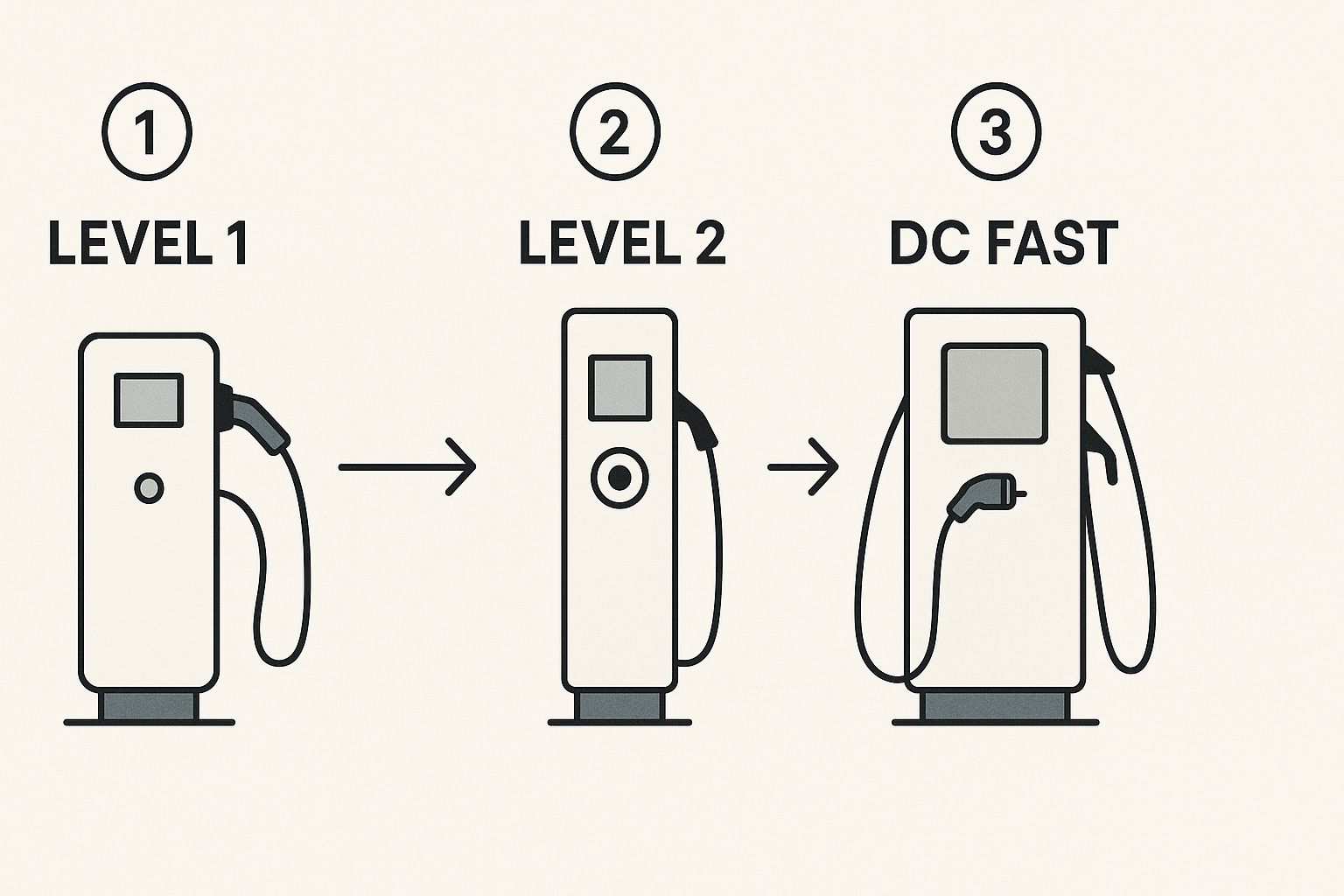

This visual guide breaks down the different types of EV chargers you’ll be considering.

As you can see, the jump from a simple Level 1 charger to DC Fast Charging is substantial in terms of electrical demand. This is precisely why a meticulous load calculation isn't just recommended—it's critical.

Executing an Accurate Load Calculation

A load calculation determines the property's total electrical demand and compares it against the main service capacity. The goal is to confirm that adding a new, dedicated circuit for an EV charger won’t push the MDB beyond its safe operational limits.

Practically, a typical Level 2 charger (7.4 kW on a single-phase supply) will continuously draw around 32 amps for hours. Your calculation must factor in:

- Total Connected Load: The sum of every electrical load in the building.

- Demand Factor: An adjustment applied based on the principle that not all appliances will operate simultaneously.

- Proposed EV Charger Load: The full amperage of the new charger circuit.

A classic mistake in the UAE is basing the load calculation only on current usage. It's crucial to inquire about the client's future plans, such as adding another AC unit or electrifying their kitchen. The MDB might have sufficient headroom today but could be overloaded tomorrow.

Once you’ve calculated the total prospective load, it must be well within the capacity of both the main incoming supply and the MDB. If the numbers indicate the panel is at or near its limit, an electrical service upgrade is mandatory. Attempting to "fit" a smaller charger into the existing capacity compromises both safety and client satisfaction.

For a precise energy management solution Dubai projects require, consider integrating smart energy meters. These devices provide real-time data to validate calculations and monitor circuit performance post-installation. You can find compliant options like Carlo Gavazzi energy meters in our GoSwitchgear online catalogue. It’s a proactive measure to guarantee system integrity and provide invaluable data to facility managers or homeowners.

Choosing the Right EV Charging Equipment for the GCC

Selecting the right hardware for an electric vehicle charger installation in the GCC is a long-term investment. The climate—characterized by intense heat, humidity, and fine dust—will quickly expose the weaknesses in subpar equipment, leading to premature failures and costly replacements. For engineers and procurement teams, the mission is to prioritize durability, compliance, and smart functionality.

The first step is to understand the three main types of chargers. Each is designed for a different application, and what works for a private villa in Dubai is unsuitable for a large commercial car park in Abu Dhabi.

EV Charger Type Comparison for UAE Applications

Not all chargers are created equal, and their demands on your electrical system are vastly different. Understanding these differences is key to planning a successful installation that meets user expectations without overloading the grid.

Here’s a practical breakdown of how the different charger levels stack up in a real-world UAE context:

| Charger Type | Charging Speed (km/hr) | Voltage Requirement | Typical Application (UAE) | Key Considerations |

|---|---|---|---|---|

| Level 1 | 5-8 km/hr | 230V Single-Phase | Very rare; mostly for emergency top-ups via standard outlets. | Impractical for daily use in the UAE due to extremely slow charging speeds. |

| Level 2 | 30-80 km/hr | 230V Single-Phase / 400V Three-Phase | Residential villas, apartment buildings, office car parks, retail centres. | The most common type for everyday charging, requiring a dedicated circuit. |

| DC Fast Charger | 300+ km/hr | 400V+ Three-Phase | Public charging hubs, motorway service stations, commercial fleet depots. | Requires substantial electrical infrastructure and significant investment. |

As this table shows, the choice directly impacts everything from user convenience to project cost. During budgeting, it's also important to weigh the financial pros and cons of leasing vs. buying equipment to determine the best asset management strategy for your project.

Climate-Proofing Your EV Charger Installation

In the UAE and KSA, the environment is the primary engineering challenge. Components must be specified to survive years of brutal, real-world conditions.

For any outdoor or semi-exposed EV charger, two specifications are non-negotiable:

- High IP Rating: An Ingress Protection (IP) rating of IP65 or higher is essential. The first digit (6) indicates complete protection against dust, while the second (5) ensures it can withstand low-pressure water jets—critical for protection against both sandstorms and routine cleaning.

- High Ambient Temperature Rating: Standard equipment is often rated for up to 40°C, which is insufficient when ambient temperatures can exceed 50°C. You must specify chargers and protection devices rated for high-temperature operation to prevent performance derating and premature failure.

I have seen installations fail within a year because the specified circuit breakers were not rated for the ambient heat inside the distribution board. Performance derating is a significant issue here; overlooking it can lead to nuisance tripping and eventual system failure.

Smart Charging Features for Energy Management

Modern EV chargers are intelligent energy management devices, essential in a region focused on sustainability and grid stability. Features like load balancing and scheduled charging are rapidly becoming standard requirements, not just optional extras.

Load balancing dynamically distributes available power across all active charging sessions, preventing the building's main supply from being overloaded. Simultaneously, scheduled charging allows users to charge during off-peak hours, reducing operational costs.

Essential Protection Components from GoSwitchgear

The charger itself is only one part of the system. The protection devices within the distribution board are equally critical for a safe, reliable installation. For every electric vehicle charger installation, using correctly rated components that meet local utility standards is mandatory.

At GoSwitchgear, we supply the professional-grade electrical components UAE experts depend on:

- Miniature Circuit Breakers (MCBs): Must be precisely sized for the charger's maximum continuous load and feature a high ambient temperature rating to prevent nuisance trips on hot days.

- Residual Current Devices (RCDs): While a Type A RCD is the minimum, we strongly recommend Type B RCDs. They are specifically designed to provide protection against the smooth DC residual currents that modern EV chargers can produce, offering a superior level of safety.

Ensuring every component is properly specified for the load, environment, and local regulations is what distinguishes a professional installation from a potential failure.

How to Navigate UAE Permitting and Regulatory Compliance

In the UAE, obtaining the correct permits for an EV charger installation is the foundation of the entire project. Collaboration with local authorities like the Dubai Electricity and Water Authority (DEWA) or the Abu Dhabi Distribution Company (ADDC) must begin from day one.

Attempting to install first and seek approval later guarantees delays, fines, and significant complications. For any engineer or contractor, the first step is to compile a comprehensive submission package for the utility's approval.

Understanding Key Documentation Requirements

The permit application serves as the engineering blueprint for your project, demonstrating that the installation will be safe, efficient, and will not place undue strain on the local power grid.

The following documents are required and must be accurate:

- Detailed Electrical Drawings: A comprehensive single-line diagram (SLD) clearly mapping the entire circuit, from the tap-in point at the main distribution board to the EV charger.

- Comprehensive Load Schedules: An updated load schedule for the entire property, detailing the building's existing load, adding the new charger's demand, and proving the total consumption remains within the main supply's capacity.

- Equipment Specifications: Datasheets for all components—EV charger, MCBs, RCDs, and cabling—to verify compliance with local standards and inclusion on the authority's approved list.

- Contractor and Electrician Credentials: Proof of valid trade licenses and certifications for both the installation company and the electricians performing the work. This is non-negotiable.

The Role of Certified Professionals and Approved Equipment

Utility authorities in the UAE mandate the use of certified electricians and authority-approved equipment for every EV charger installation. There are no shortcuts.

This is a critical safety and quality control measure. Using unlisted components or an unlicensed contractor will result in immediate application rejection and a failed final inspection. The UAE's commitment to quality is a key reason for its leadership in building out a safe and reliable EV infrastructure.

A common point of failure is submitting incomplete or inaccurate single-line diagrams. If the diagram does not perfectly match the proposed load schedule and the site reality, DEWA or ADDC will return it, adding weeks to the project timeline.

Final Inspection and Securing the Completion Certificate

Once the charger is installed, the final step is to schedule the final inspection with the utility. An inspector will visit the site to verify that the work matches the approved drawings and complies with all local electrical codes. Understanding general construction permit requirements can provide context for these processes.

The inspector's checklist includes:

- Correct wiring methods and secure terminations.

- Proper installation of safety devices like RCDs and MCBs.

- Correct earthing and bonding.

- Physical mounting and placement of the charger.

- Use of appropriate cabling and conduit, a topic covered in our guide on selecting GI electrical conduits for projects in the UAE and GCC.

Only upon the inspector's satisfaction will the authority issue the official completion certificate, confirming the installation is compliant, safe, and ready to be energized.

Wiring Installation and Essential Safety Practices

With the site assessed and equipment selected, the physical installation is where technical skill is paramount. For electricians and panel builders in the UAE, this stage is a direct measure of craftsmanship and commitment to safety. It involves understanding circuit integrity, protecting against the harsh environment, and adhering to critical safety protocols.

The first step is always to run a dedicated circuit directly from the main distribution board (MDB) to the charger's location. This is non-negotiable for any Level 2 or DC Fast Charger. Sharing a circuit is a major code violation and a serious fire hazard due to the high, sustained power draw.

Selecting the Correct Wire Gauge

Correct wire gauge selection is crucial to prevent voltage drop, a common issue in larger properties or where the charger is located far from the electrical panel. Voltage drop can slow charging speeds and damage the EV charger over time.

The calculation must balance the charger's amperage and the total cable run length. For a standard 32A Level 2 charger, a 6mm² wire might seem adequate. However, if the cable run exceeds 30 meters, upgrading to 10mm² may be necessary to maintain performance. Always consult local wiring regulations and the manufacturer's datasheet.

In the GCC, outdoor installations are common, making wiring protection vital. Galvanized iron (GI) conduit is standard practice, providing necessary mechanical protection and shielding cables from intense UV radiation and high ambient heat.

Ensuring Secure and Compliant Terminations

Clean, tight terminations are the hallmark of a professional. Every connection point—from the MCB in the panel to the terminals inside the charger—must be torqued to the manufacturer’s specifications. A loose connection creates resistance and generates heat, a primary cause of electrical fires.

Using the correct lugs and connectors for the wire size is also vital. For larger projects, knowing how to select the right bus bar connectors for UAE climates is key to maintaining integrity within the MDB.

A frequently missed detail is the cumulative effect of heat inside the MDB. In the UAE's climate, a panel is already warm, and the continuous load from an EV charger increases the temperature further. This can push components beyond their limits. Using high-temperature rated wiring and breakers is a necessity.

Implementing Critical Safety Protocols

Safety is paramount in an electric vehicle charger installation. This extends beyond standard best practices to include specific protections required by EV charging systems.

The most important safety device is the Residual Current Device (RCD). While a standard Type A RCD protects against AC faults, EV chargers can introduce smooth DC leakage currents that can "blind" a Type A device, rendering it ineffective during a fault.

Therefore, installing a Type B RCD is industry best practice and increasingly a regulatory requirement. It is specifically designed to detect both AC and smooth DC residual currents, providing comprehensive protection against electric shock.

Before energizing the system, perform these final checks:

- Earthing Verification: Confirm a solid, low-impedance path to earth to ensure protective devices trip instantly during a fault.

- Insulation Resistance Test: This pre-power-up test confirms there are no hidden faults or shorts in the new cabling.

- Polarity Check: A final verification that live, neutral, and earth are correctly wired at both the panel and the charger.

Adhering to these strict wiring and safety practices ensures your installation not only meets DEWA and ADDC standards but is also durable and safe for the end-user.

Commissioning Your Installation and Client Handover

The final stage—commissioning and handover—is where your professionalism is sealed. This process verifies that the system is safe, functional, and ready for use. For any engineer or electrician in the UAE, a diligent commissioning process is the final mark of quality.

After the physical installation is complete and the utility inspection is passed, a series of final tests must be conducted before client handover. This is the last opportunity to identify any hidden issues.

Essential Functional and Safety Tests

A structured testing sequence is non-negotiable and provides proof of a perfectly performing system upon departure.

Your checklist should include:

- Voltage and Polarity Checks: Use a multimeter to confirm correct voltage at the charger terminals and verify that live, neutral, and earth wires are correctly positioned.

- RCD Trip Test: Use an RCD tester to manually trip the circuit's protective device, proving it will function correctly during a real fault.

- Charging Initiation Test: Use an EV or a dedicated EVSE tester to simulate a charging cycle, ensuring a proper "handshake" between the charger and the vehicle.

- Load Test: Allow the charger to run under load while monitoring the circuit to confirm a steady amperage draw and no signs of thermal stress at connection points.

Conducting a Professional Client Handover

A thorough handover empowers the client and reinforces your company's expertise.

Your handover should cover:

- Demonstrating how to start and stop a charging session.

- Explaining the meaning of different status lights or screen messages.

- Showing them how to use smart features like scheduled charging via the mobile app.

The goal of the handover is to preemptively answer questions. A confident client is more likely to provide positive reviews and referrals. This final interaction is a crucial opportunity to leave a lasting positive impression.

Finally, provide a complete documentation package, including the charger's user manual, warranty details, and, most importantly, the official completion certificate from DEWA or ADDC. This certificate is their proof of a fully compliant and legally approved installation.

This comprehensive approach not only guarantees a safe and reliable charger but also cements your reputation as a trusted expert in a booming market. The electric vehicle charging infrastructure market in the Middle East and Africa is projected to grow at a CAGR of 27.7% between 2025 and 2030. You can read the full research about the MEA's EV infrastructure growth to understand the scale of this opportunity.

Ready to Power Up Your Next EV Charger Project?

This guide provides a roadmap for successful electric vehicle charger installations in the UAE. From the initial site assessment and selection of climate-resilient equipment to navigating local regulations and performing final commissioning checks, mastering each step is key to a safe, durable installation. For projects in Dubai, Abu Dhabi, or across the GCC, a knowledgeable supplier is essential.

At GoSwitchgear, we provide more than just high-quality, compliant electrical components. We offer the technical expertise to support you from design to final commissioning, ensuring every component is perfectly suited for the demanding conditions of our region. Let's collaborate to make your next installation a benchmark for excellence.

Need technical advice or a quote for an upcoming project? Explore our extensive catalogue or get in touch with our local teams.

Find the electrical components you need at GoSwitchgear.com.

Leave a Reply