A Guide to Three Phase Motor Connection in the UAE

Getting a three-phase motor connection right doesn't start with touching a single wire. It begins the moment you lay eyes on the motor's nameplate. Think of that little metal plate as the motor's technical passport; reading it correctly is absolutely critical for safe, reliable operation, especially in the tough industrial environments we see across the UAE and the wider GCC.

Decoding the Nameplate for GCC Applications

That nameplate is much more than a simple label. For any engineer or electrician in Dubai, Abu Dhabi, or anywhere in the region, it's the definitive guide to the motor's capabilities and limits. Getting this part wrong can lead to costly failures and cut the equipment's lifespan short. The data here dictates everything, from how you'll wire it up to which protective devices you'll need from a supplier like GoSwitchgear.

Dual Voltage Ratings and Connection Choice

One of the first things you'll notice is the voltage rating, which is often a dual value like 400V/690V. This isn't a range the motor can operate in; it's a strict instruction that tells you exactly how to connect the motor based on your supply voltage.

- Low Voltage (400V): This number is for the Delta (Δ) connection. When you're hooking it up to a standard 400V supply here in the UAE, the motor must be wired in delta. This ensures each winding gets the correct voltage so the motor can deliver its full rated power.

- High Voltage (690V): This value corresponds to the Star (Y) connection. The motor is designed to run on a 690V supply when wired this way. On a 400V supply, the star connection is only used temporarily during a Star-Delta start to reduce that big inrush of current.

A common and destructive mistake is to permanently run a 400V/690V motor in a star connection on a 400V supply. This starves the windings of voltage, leading to weak torque, poor efficiency, and almost certain overheating when the motor is under load.

Environmental Suitability: IP Ratings and Insulation Class

The GCC climate throws everything at electrical equipment—extreme heat, humidity, and plenty of airborne dust. Two ratings on the nameplate are non-negotiable for making sure a motor can survive out here.

The IP (Ingress Protection) rating tells you how well the motor's enclosure is sealed. For a dusty industrial site in Jebel Ali or Jubail, you should be looking for a minimum of IP55. The first '5' means it's protected from dust getting in, and the second '5' means it can handle low-pressure water jets.

The Insulation Class (you'll see things like Class F or Class H) specifies the highest temperature the motor's winding insulation can handle. Class F, for example, allows for a temperature rise of 105°C above a 40°C ambient temperature. Since we can easily see ambient temperatures higher than that in the GCC, specifying a motor with a higher insulation class gives you a vital safety margin.

Performance and Overload Protection

The nameplate also gives you the exact numbers you need to select the right protective gear, like motor circuit breakers and thermal overload relays.

- Full Load Amperes (FLA): This is the current the motor pulls when it's working at its rated power. You need to set your overload relay based on this value to protect the motor from damage.

- Service Factor (S.F.): If you see a service factor above 1.0 (like 1.15), it means the motor can handle a temporary overload—in this case, 15% above its rated power. This is great for applications with occasional power spikes, but you can't rely on it for continuous operation.

In the UAE and across the Middle East, the three-phase induction motor is the workhorse of the industrial sector. Market analyses point to steady growth, pushed by manufacturing, oil and gas, and construction. These simple, tough motors are everywhere—in pumps, HVAC systems, and heavy machinery—which makes knowing how to read a nameplate a fundamental skill for any professional working here. You can find more details in this market research on three-phase induction motors.

Okay, let's get this section rewritten to sound like it's coming from an experienced engineer on the ground, not a textbook. Here is the revised version, following all the specified requirements.

Star or Delta? Making the Right Motor Connection

Once you've got the nameplate details sorted, you’re faced with the next big question for any three phase motor connection: do you wire it in Star (Y) or Delta (Δ)? This isn't just about following a diagram; it's a decision that directly controls the motor's starting kick, its running torque, and how it behaves on the grid. Getting this right is fundamental, especially with the power systems we work with here in the UAE.

The whole game hinges on two things: the voltage ratings stamped on the motor (like 400V/690V) and your supply voltage, which is a standard 400V across the GCC. The principle is straightforward: each winding inside that motor is built to handle a specific voltage. Your wiring choice—Star or Delta—decides exactly how much of that 400V supply hits each winding.

The Star Connection: Taming the Inrush Current

Think of the Star (or Y) connection as your tool for a soft start. In this setup, you tie the ends of the three motor windings (W2, U2, V2) together to create a central neutral point. The three-phase power (L1, L2, L3) then feeds into the start of each winding (U1, V1, W1).

This simple trick dramatically lowers the voltage across each winding—down to about 58% of the line voltage. On our typical 400V supply, that means each winding only sees around 230V.

And that voltage drop is the whole point. By slashing the voltage, you cut the starting current down to roughly one-third of what it would be in Delta. This is why the Star connection is the first stage in any Star-Delta starter. It’s used for just a few seconds to ease the motor onto the grid without causing a massive electrical jolt.

The Delta Connection: Unleashing Full Power

When you need the motor to do some real work, you turn to the Delta (Δ) connection. This is where the motor delivers its rated power and torque. Here, the windings are linked end-to-end, forming a triangle (the "delta"). You'll connect U1 to W2, V1 to U2, and W1 to V2, with your three-phase supply hitting those junction points.

Wired in Delta on a 400V line, each winding gets the full 400V. This is what lets the motor flex its muscles and produce the maximum torque it was designed for. For demanding jobs—think heavy-duty compressors, loaded conveyor belts, or industrial mixers—running in Delta is the only way to go. It’s the standard running configuration for most motors in the region.

How It All Comes Together in the GCC

So, which one do you choose? Often, you don't have to pick just one. The most common real-world application here is the Star-Delta starter, which is practically a requirement for motors bigger than 5.5 kW to keep the local utility providers happy by limiting that initial current surge.

The process is clockwork simple:

- Startup in Star: The motor kicks on in the Star configuration for a few seconds. Torque is low, but more importantly, the current draw is gentle on the network.

- The Switchover: After a set time, the starter briefly disconnects and quickly reconnects the windings into a new shape.

- Run in Delta: The motor is now in its Delta configuration, running at full power and ready to handle its intended load.

Of course, pulling this off correctly means using the right motor starter and control components. Sourcing quality, reliable gear from a supplier like GoSwitchgear is key to building a panel that works flawlessly day in and day out.

To make the choice crystal clear, here’s a quick table comparing the two connections for a standard 400V system you'd find anywhere in the UAE.

Star (Y) vs. Delta (Δ) Connection at a Glance for 400V Systems

For engineers and electricians in the field, knowing when to use each connection is crucial for performance and compliance. This table breaks down the key differences in a practical context for the UAE.

| Parameter | Star (Y) Connection | Delta (Δ) Connection | Typical UAE Application |

|---|---|---|---|

| Voltage Across Winding | Reduced (230V from 400V supply) | Full Line Voltage (400V) | Full-load operation for most industrial machinery (pumps, fans, conveyors) |

| Starting Current | Low (approx. 1/3 of Delta) | High (Full inrush current) | Initial phase of a Star-Delta start to limit current draw |

| Starting Torque | Low (approx. 1/3 of Delta) | High (Full rated torque) | Applications requiring high starting torque, like loaded conveyors or compressors |

| Primary Use Case | Temporary starting method | Continuous running connection | Standard operational mode for motors rated 400V on a 400V supply |

Ultimately, Star is for starting gently, and Delta is for running hard. Understanding this distinction is fundamental to commissioning three-phase motors safely and efficiently.

Selecting the Right Motor Starter for Your Application

Wiring up your motor is just step one. The real magic—and the key to its longevity and performance—lies in how you start it. A motor starter is far more than a simple on/off switch; it’s the crucial piece of hardware that tames the immense stress of startup. For any three phase motor connection in a demanding industrial setting, this isn't a component you can afford to overlook.

The right starter depends on the motor's size, the job it's doing, and, especially in places like Dubai and Abu Dhabi, your energy efficiency targets. From a basic contactor to an intelligent drive, the control gear you choose is every bit as important as the motor itself.

The Workhorse: Direct-On-Line (DOL) Starter

For smaller three-phase motors, usually those under 5.5 kW, the Direct-On-Line (DOL) starter is the undisputed champion. It's straightforward, tough as nails, and doesn't break the bank. A DOL starter hits the motor with the full 400V supply right from the get-go, giving you 100% of the starting torque in an instant.

That brute-force approach is exactly what you need for applications that require a powerful kick to get going, provided your electrical supply can handle the massive inrush current (often 5-8 times the motor's running current).

- Components: A DOL starter is simple, typically made up of a main contactor and a thermal overload relay, often backed by a motor protection circuit breaker (MPCB).

- Best Use Case: Perfect for small water pumps, compressors, fans, and workshop machines where you value simplicity and low cost.

- GCC Consideration: In the UAE's high ambient temperatures, make sure the thermal overload relay is sized and set correctly. Otherwise, you'll be dealing with nuisance tripping all day long.

The Regional Favourite: Star-Delta Starters

Once you get into larger motors, that huge inrush current becomes a serious problem. The Star-Delta starter is the classic, field-proven solution. It's a favorite across the GCC because it strikes the perfect balance between performance, mechanical simplicity, and cost—a true staple for panel builders.

Here’s how it works: the starter first connects the motor windings in a star configuration. This simple trick slashes the starting current down to about one-third of what it would be otherwise. After a few seconds, once the motor is up to speed, a timer triggers a set of contactors to switch the connection over to delta for full-power running.

This two-stage start significantly softens the blow on the electrical grid. This isn't just good practice; it's often a requirement to comply with local utility regulations in the UAE and Saudi Arabia, which frequently mandate reduced-voltage starting for motors above a certain size.

Modern Control with Soft Starters and VFDs

While Star-Delta is a clever mechanical fix, modern electronics offer a much more elegant solution. A Soft Starter uses thyristors to gently ramp up the voltage sent to the motor, delivering a perfectly smooth, stepless acceleration.

This is a game-changer for applications where mechanical shock is the enemy, like conveyor belts or complex pumping systems. It completely eliminates the jarring jolt of a DOL or Star-Delta start, protecting not just the motor, but also the gearboxes, belts, and couplings connected to it.

For the absolute peak of control and efficiency, however, you need a Variable Frequency Drive (VFD). A VFD doesn't just give you a smooth start; it gives you total control over the motor's speed while it's running. By precisely matching motor speed to the actual process demand, a VFD can deliver massive energy savings—a huge win for any facility in Dubai with an eye on sustainability.

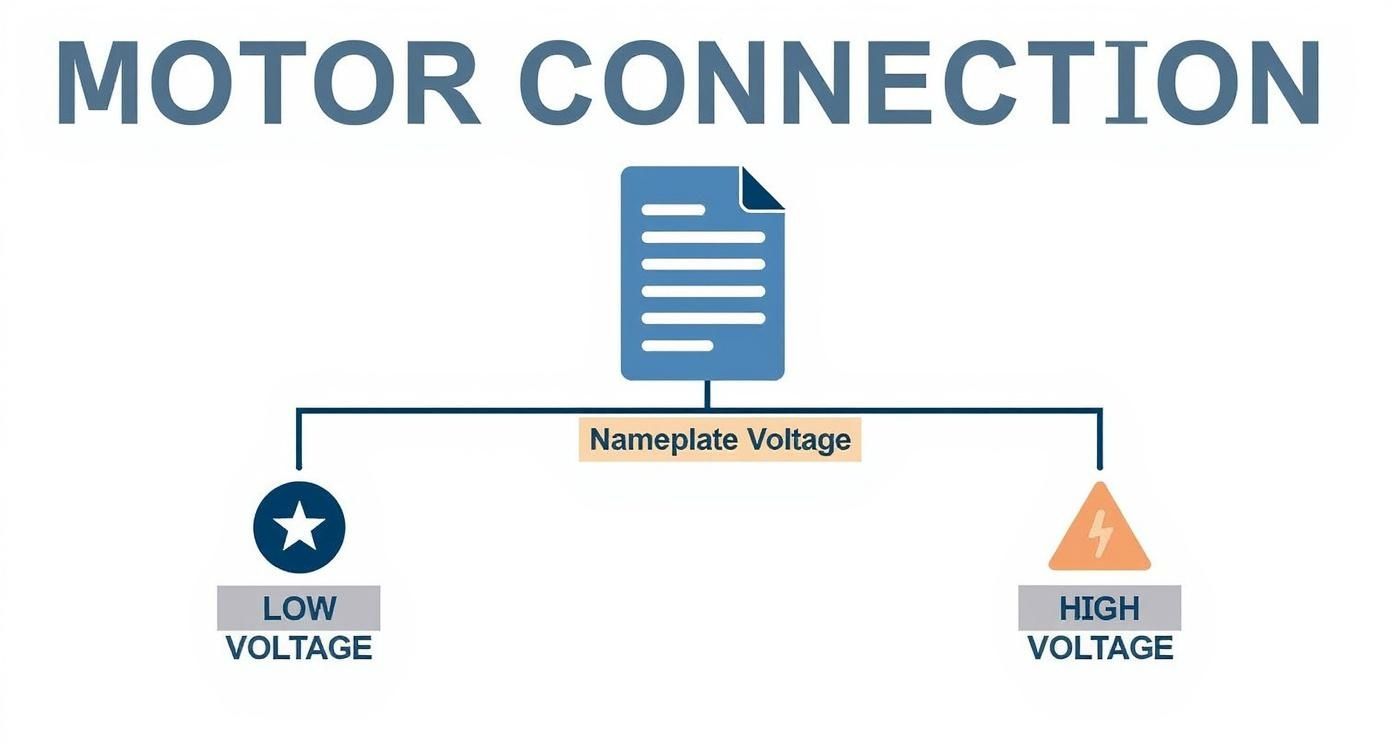

This infographic is a great starting point for figuring out your connection based on the motor's nameplate.

As the visual shows, for a dual-voltage motor, the higher voltage rating (e.g., 400V) aligns with a star connection, while the lower rating (e.g., 230V) is meant for a delta connection, depending on your local supply.

The adoption of these advanced controllers is booming. In 2023, the global market for three-phase automatic motor starters was valued at over USD 2.1 billion, and with the GCC's industrial growth, that number is set to climb. These starters are absolutely essential for managing motor operations and protecting them from faults, which has a direct impact on productivity. You can dive deeper into these trends in this detailed industry analysis.

Whether you need a rock-solid Star-Delta setup or a high-efficiency VFD, getting the right electrical components in the UAE is what matters most. At GoSwitchgear, we stock a full range of motor starters and protection devices designed to meet the real-world demands of your projects.

Essential Pre-Commissioning Checks and Safety Protocols

Before you even think about flipping the switch, a solid pre-commissioning process is what stands between a smooth startup and a potentially dangerous, expensive mess. For any three phase motor connection project, especially here in the UAE, this isn't just a good idea—it's an absolute must. Think of these checks as your last line of defense to spot any wiring mistakes, weak insulation, or safety issues before the system goes live.

The whole point is to double-check the integrity of your installation and guarantee the safety of everyone on site. It involves a mix of physical tests and sharp-eyed visual inspections to confirm the motor and its control gear are truly ready for power. Skipping this part is a gamble no professional should ever be willing to take.

Lock-Out/Tag-Out (LOTO) and Safe Work Practices

Safety isn’t just an item on a list; it's the foundation of everything we do. Before you touch a single wire, the circuit needs to be completely dead and locked down. This is where Lock-Out/Tag-Out (LOTO) procedures are non-negotiable.

- Isolation: First, kill the power. The main circuit breaker or isolator feeding the motor starter must be switched to the 'OFF' position.

- Lock-Out: Next, slap a physical lock on that isolator. This physically stops anyone from accidentally flipping it back on while you're working.

- Tag-Out: Finally, attach a highly visible warning tag. It should clearly state that the circuit is being worked on and must not be touched.

Having clearly defined Safe Operating Procedures is critical for managing risk during connection and commissioning. These documents give every technician a consistent, proven process to follow, ensuring safety rules are understood and followed every single time.

Insulation Resistance Testing with a Megger

In the humid climate we have in the GCC, insulation failure is a very real problem. Moisture is the enemy; it can get into motor windings and create the perfect conditions for a short circuit. Your best tool against this is an insulation resistance test, which most of us just call a "megger" test.

This test works by applying a high DC voltage (usually 500V or 1000V) between the motor's windings and its metal frame (earth). A motor in good shape will show an extremely high resistance—we're talking hundreds of megaohms (MΩ). If you get a low reading, it's a red flag. It means current has found a sneaky path to the ground, signaling damaged insulation that needs to be addressed immediately.

For any new motor going in here in the UAE, I always look for a minimum reading of 10 MΩ. Anything lower than that, and I'm putting the brakes on commissioning until we figure out why. This one simple test can save a motor from burning out on its very first run.

Verifying Continuity and Correct Connections

A quick continuity test might seem basic, but it's crucial for confirming that your wiring is solid with no breaks. Grab your multimeter, set it to resistance or continuity mode, and check a few key things:

- Winding Integrity: Measure the resistance across each winding (U1-U2, V1-V2, W1-W2). The three readings should be nearly identical and very low, typically just a few ohms. A significant difference points to a problem inside the motor.

- Connection Tightness: Go through and physically check that every terminal screw—both in the motor's terminal box and in the starter panel—is properly torqued down. Loose connections are one of the biggest causes of overheating and failure down the line.

- Absence of Shorts: Make sure there's no continuity between the different phase windings (like between U1 and V1). A reading here means you have a short circuit.

Confirming Phase Sequence and Rotation

Last but not least, you have to be certain the motor will spin the right way. This is absolutely critical for equipment like pumps, fans, and compressors. Running them backward can cause immediate and severe mechanical damage. The right tool for the job is a phase sequence meter.

This handy device connects to your incoming L1, L2, and L3 phases and tells you the direction of rotation (clockwise or counter-clockwise). By confirming the phase sequence at the starter matches what the equipment needs, you're not just guessing—you're preventing a potentially catastrophic reverse start.

Working through these checks step-by-step ensures your three phase motor connection is not just working, but is fundamentally safe and built to last from day one.

Commissioning and Troubleshooting Common Faults

Alright, with all the prep work done, it's time for the moment of truth: bringing the motor to life. This is where your careful planning pays off. Commissioning isn't just about flipping a switch; it's a systematic process to confirm your three phase motor connection is spot-on and ready for the long haul, especially in the demanding UAE climate.

This final stage is all about checking performance under real-world conditions and setting a baseline for future maintenance. A smooth commissioning means the equipment runs efficiently from day one and helps you catch small issues before they snowball into major downtime.

The Initial Bump Test and Current Measurement

First things first: before you couple the motor to its mechanical load, you need to do a "bump test." This is a quick, momentary start-up just to see which way the shaft spins. For equipment like pumps or screw compressors, getting the rotation wrong can lead to instant, catastrophic damage.

If it’s spinning the wrong way, no sweat. Just swap any two of the incoming phases (say, L1 and L2), and you'll reverse the direction. Simple as that.

Once you’ve confirmed the correct rotation, go ahead and couple the motor to the load and let it run. Now, grab your clamp meter and measure the running current on all three phases (L1, L2, and L3). Here’s what you’re looking for:

- Balanced Currents: The amp readings on all three phases should be nearly identical. A significant imbalance—anything more than 5-10%—is a big clue that something's wrong. It could be a poor connection, an internal winding fault, or even an issue with the power supply itself.

- FLA Compliance: Check your readings against the Full-Load Ampere (FLA) value stamped on the motor’s nameplate. The running current should never exceed this number. If it does, that’s a major red flag. The motor is overloaded and is on a fast track to overheating.

Troubleshooting Common Field Issues in the GCC

Even a flawless installation can run into trouble, especially here in the GCC. The combination of high ambient temperatures, dust, and voltage fluctuations creates a perfect storm for motor faults. Here’s a practical rundown of how to diagnose the most common ones.

Overheating and Nuisance Tripping

This is the number one problem we see, especially during the sweltering summer months. If an overload relay keeps tripping, it's almost always a symptom of a bigger issue.

- Check Ventilation: Is the motor's cooling fan clean? Can air flow freely over the cooling fins? Dust and grime are notorious for trapping heat.

- Verify Ambient Temperature: Is the motor stuck in a hot, unventilated room or baking in direct sunlight? High ambient heat drastically reduces the motor's ability to cool down, pushing it past its insulation class limits even under a normal load.

- Confirm Voltage: A low voltage supply is a silent killer. It forces the motor to draw more current to deliver the same power, which inevitably leads to overheating. Check the voltage right at the motor terminals while it's running.

Excessive Vibration or Noise

A happy motor runs smooth and quiet. If you start hearing new rumbles or feeling excessive vibration, you need to investigate right away.

- Mechanical Alignment: Nine times out of ten, the cause is poor alignment between the motor and the equipment it’s driving. Double-check the coupling.

- Bearing Wear: Worn-out bearings are another usual suspect. They often make a distinct grinding or rumbling sound that gets worse over time.

- Unbalanced Load: Make sure the driven equipment, like a fan or pump impeller, is balanced correctly and isn't clogged with debris.

A logical troubleshooting process saves time and prevents you from replacing parts you don't need to. Always start with the simple stuff—loose connections, blocked vents—before you dig into more complex diagnostics like insulation resistance tests on a hot motor.

The industrial scene in the UAE is rapidly evolving, with a strong push towards more advanced motor technologies. We're seeing a significant rise in the use of medium-voltage synchronous motors across the Middle East and Africa (MEA), especially in critical sectors like power generation and desalination. Projections show this market growing from USD 307.3 million in 2024 to nearly USD 427.77 million by 2032. This growth is all about boosting energy efficiency with smarter controls like VFDs. You can read more about these trends in medium-voltage motors. This shift just goes to show how crucial precise commissioning and diagnostic skills have become.

Frequently Asked Questions About Motor Connections

Out in the field, you're bound to run into questions when dealing with a three phase motor connection. This section cuts through the noise and tackles some of the most common queries we hear from engineers and electricians across the UAE. We'll give you clear, straightforward answers to help you solve problems right there on site.

What Happens If You Connect a Three-Phase Motor Incorrectly?

Getting the connection wrong can lead to immediate and severe damage. The classic mistake is swapping two of the incoming phases. Do that, and you'll force the motor to spin in the opposite direction. For equipment like centrifugal pumps or compressors, reverse rotation isn't a minor hiccup—it can cause catastrophic mechanical failure in a matter of seconds.

Another critical error is picking the wrong winding connection. Picture this: you have a motor rated for 400V/690V. If you connect it in Delta on a 690V supply when it should be in Star, you've just massively over-voltaged the windings. The result is an enormous current draw, rapid overheating, and a motor that's very likely to burn out completely.

Why Is the Starting Current So High in a Three-Phase Motor?

Think of a three-phase induction motor at a standstill. Its windings have incredibly low impedance. When you hit the "start" button, there's no back electromotive force (EMF) from the rotor yet to push back against the incoming voltage.

For a brief moment, the motor acts almost like a short circuit, pulling in a massive inrush current. This surge is typically 5 to 8 times its normal full-load running current. This is exactly why motor control gear like Star-Delta starters or Soft Starters are non-negotiable for larger motors in the GCC—they're specifically designed to soften that initial electrical blow.

Can I Run a Three-Phase Motor on a Single-Phase Supply in the UAE?

While it's technically possible with the right gear, it's a solution we strongly discourage for any professional application. The usual methods involve a static phase converter or, more effectively, a Variable Frequency Drive (VFD) that can take a single-phase input and generate a balanced three-phase output.

But this approach is full of compromises.

- Power De-rating: You'll almost always have to de-rate the motor, which means it won't deliver its full rated horsepower. You could lose as much as 30-40% of its power.

- Reduced Efficiency: The motor simply won't run as efficiently as it would on a native three-phase supply, which means higher energy bills.

- Potential for Imbalance: Less expensive converters can produce an unbalanced three-phase output, leading to motor vibration, excess noise, and overheating.

In the UAE's industrial and commercial landscape, a dedicated three-phase supply is the standard for a very good reason. Relying on phase conversion should be a last-ditch effort for a small workshop or a remote site where three-phase power is simply not an option. For any serious job, securing a proper three-phase source is the only reliable way to guarantee long-term motor performance.

For robust motor control solutions built to handle the GCC's demanding operational environment, you can count on GoSwitchgear. Take a look at our extensive range of motor starters, protection devices, and electrical components today.

Find the right motor starter for your project on GoSwitchgear

Leave a Reply