A Guide to Lightning Protection Systems for UAE & GCC Infrastructure

For engineers and facility managers in the UAE and GCC, lightning is more than a weather event—it's a significant financial risk. A direct strike can cause catastrophic structural damage, but the secondary electrical surges often prove more destructive, capable of destroying sensitive operational technology and causing extensive downtime.

Why Modern UAE Infrastructure is Uniquely Vulnerable

The advanced infrastructure across the UAE and wider GCC region is especially susceptible to lightning's destructive power. Ambitious architectural designs, vast metal structures, and interconnected digital systems create a perfect pathway for electrical energy to cause chaos. Without a robust lightning protection system, the operational and financial fallout can be devastating.

A single strike can send powerful surges through power and data lines, instantly disabling critical equipment. This isn't just about replacing a few components; it's about preventing a domino effect of failures that can halt production, compromise building safety, and lead to costly downtime. The risk is even greater in facilities reliant on networked control systems, common in Dubai's smart buildings and Saudi Arabia's industrial plants.

Key Vulnerabilities for GCC Facilities

Engineers and procurement teams in the region face unique risk factors:

- Architectural Complexity: Iconic, geometrically complex structures with large surface areas offer multiple potential strike points, demanding a highly detailed protection strategy.

- Sensitive Electronics: Modern commercial and industrial buildings run on low-voltage PLCs, servers, HVAC controls, and advanced security systems, making them extremely vulnerable to electrical surges from a nearby strike.

- Interconnected Systems: A surge entering one part of a facility can easily propagate through the shared electrical network, causing widespread damage far from the initial impact point.

For decision-makers, the calculation is straightforward. The upfront investment in a comprehensive lightning protection system, sourced from a reliable partner like GoSwitchgear, is minimal compared to the potential multi-million-dirham cost of equipment replacement, operational disruption, and reputational damage. It is a foundational element of risk management for any modern facility in the UAE.

How a Lightning Protection System Really Works

It’s a common misconception that a lightning protection system (LPS) acts as a force field to stop a lightning strike. In reality, a well-designed LPS creates a safe, controlled pathway for lightning's immense energy, guiding it from the point of impact directly into the ground.

Think of it as an electrical traffic management system for your building. Without this dedicated path, a current exceeding 100 million volts will carve its own destructive route through your facility—blasting through steel frames, concrete, wiring, or sensitive electronics. This is what causes fires, explosive structural damage, and a total failure of critical systems.

At its core, a properly designed system envelops your structure in what is known as a Faraday cage. This principle ensures the massive electrical charge remains on the exterior of the conductive path, keeping people and technology inside safe. The process involves three key stages working in perfect synchronisation.

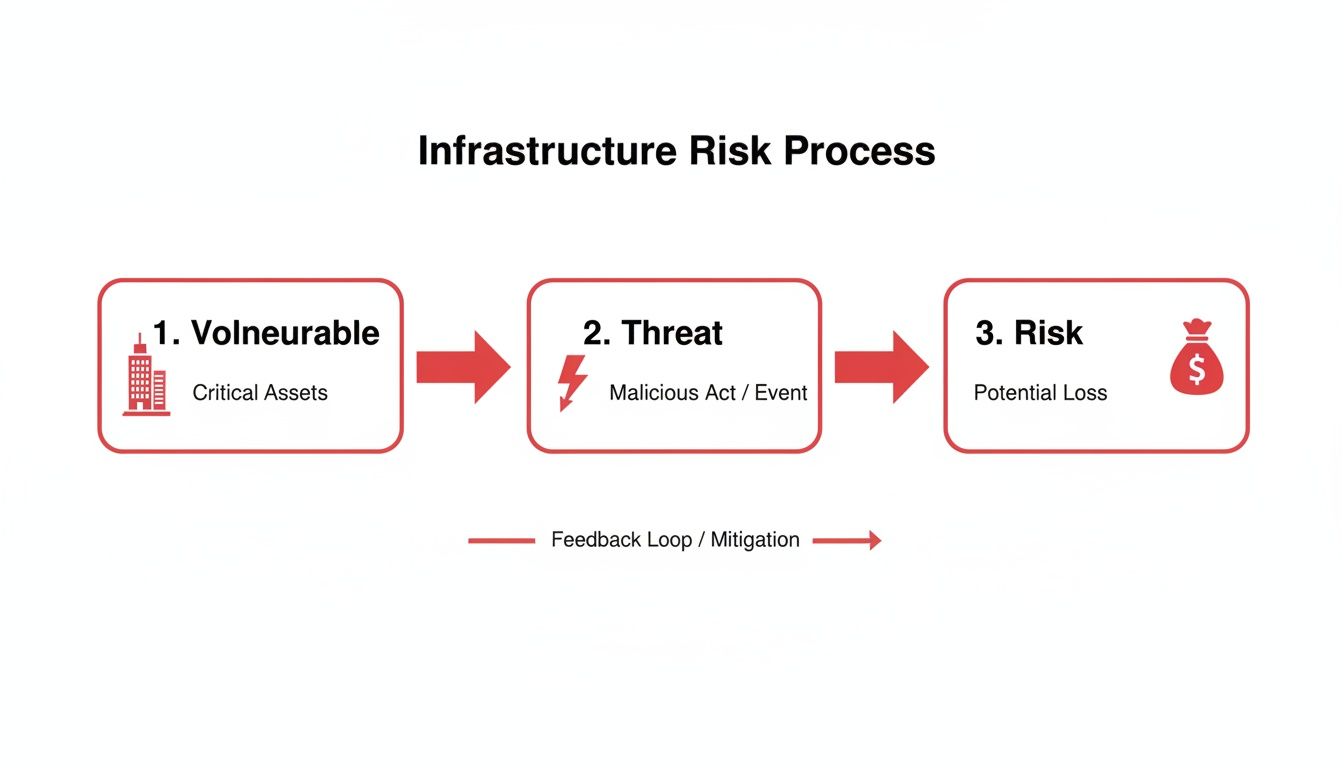

This flowchart illustrates the direct line between an unprotected asset and the significant financial risks a lightning threat represents.

As shown, without the right mitigation measures, a natural threat quickly escalates into a major financial loss, making lightning protection a non-negotiable investment.

Stage 1: Interception

The first objective is to intercept a lightning strike before it connects with a vulnerable part of your building. This is the function of the air termination system, which consists of strategically placed lightning rods or a network of conductors.

These components are installed at the highest points of a structure—such as roof peaks, parapets, and atop exposed equipment like HVAC units or communication antennas. Their purpose is to be the most attractive target for a developing lightning strike, inviting it to hit the protection system instead of the building itself. Their placement is meticulously calculated using methods defined in standards like IEC 62305 to ensure complete coverage.

Stage 2: Conduction

Once the strike is intercepted, the enormous electrical current requires a safe path from the roof down to the ground. This is the role of the down conductor system, a network of heavy-duty copper or aluminum cables running down the building's exterior.

These conductors serve as express lanes on the electrical highway. They must provide a direct, low-resistance path to the ground and be routed to avoid sharp bends. A sharp turn could cause the energy to arc or "side-flash" to other metallic parts of the building, such as window frames or internal wiring, with disastrous consequences.

A key challenge for panel builders and electricians in the UAE is ensuring all metallic services—like water pipes, gas lines, and data cables—are correctly bonded to the lightning protection system. Proper equipotential bonding prevents dangerous voltage differences from developing between different conductive parts of the building during a strike.

Stage 3: Dissipation

The final and most critical stage is to safely dissipate the electrical energy into the earth. The earth termination system handles this vital task, typically consisting of long, copper-clad steel rods driven deep into the ground or a grid of buried conductors.

Its function is to create a large surface area of contact with the earth, allowing the immense current to spread out and neutralize without causing a dangerous rise in ground potential. Here in the UAE and wider GCC, achieving a low-resistance earth connection in our often dry, sandy soil can be challenging. This frequently requires specialized solutions, such as ground enhancement materials or more extensive earthing arrays, to ensure the system performs correctly.

Without proper dissipation, the energy has nowhere to go but back up into your facility, defeating the purpose of the entire system.

The Three Pillars of a Comprehensive Protection System

An effective lightning protection system is not a single piece of equipment but a carefully engineered network of three critical parts working together to capture, control, and safely neutralize the power of a lightning strike.

For any engineer or panel builder in the UAE, understanding how these elements synchronize is the first step toward designing a system that can withstand our region's unique climate and architectural demands.

Think of it as creating a protective shield around the entire structure, providing a safe, designated path for the destructive electrical current to follow, away from people and valuable assets.

Pillar 1: Air Terminals for Safe Interception

The first line of defense is the air termination system. Commonly known as lightning rods, they can also be an interconnected grid of conductors. Their job is to be the most attractive point for a lightning strike.

They are strategically placed at the highest points of a building—along rooflines, on parapets, and on exposed equipment. This placement is a science, often determined using the Rolling Sphere Method, a design technique from the IEC 62305 standard.

Imagine rolling a large sphere over a 3D model of the building. Any point the sphere touches is a potential strike zone and requires an air terminal. This method ensures there are no gaps where lightning could bypass the system.

In the GCC, where skylines are dominated by iconic high-rises, this first pillar is essential. With 19 of the world's tallest buildings located in the Middle East, including Dubai's Burj Khalifa which is struck regularly, advanced protection is non-negotiable.

Pillar 2: Down Conductors for Controlled Conduction

Once the air terminal has intercepted the strike, the immense electrical charge needs a safe path to the ground. This is the job of the second pillar: the down conductor system.

This is a network of highly conductive cables, typically copper or aluminum, running from the air terminals down the building's exterior.

The routing of these conductors is critical. If a conductor runs too close to metal cladding, window frames, or internal wiring, the current can jump across the gap—a dangerous phenomenon called a "side-flash."

Best practices for installing down conductors include:

- Maintaining clearance from other metallic parts of the building.

- Creating the most direct path from the roof to the ground.

- Securing them tightly to handle the high winds and temperature fluctuations common in the UAE climate.

Pillar 3: Earth Termination for Final Dissipation

The final and most important pillar is the earth termination system, where all captured energy is safely dispersed into the ground.

This system is usually made up of copper-clad steel rods driven deep into the earth or a buried grid of conductors. The goal is to create a path of least resistance for the electricity to flow into the soil.

A low-resistance path to ground is the single most critical factor in a lightning protection system's performance. If energy cannot dissipate effectively, it can create a dangerous rise in ground potential, potentially flowing back into the facility's electrical systems.

Achieving this low resistance is a significant challenge in the sandy, often dry soils across the UAE and KSA, which have high electrical resistivity. To combat this, we often use specialized solutions:

- Ground Enhancement Materials (GEM): Conductive compounds packed around earth rods to increase their effective surface area and lower overall resistance.

- Deeper Earth Rods: Driving rods deeper to reach more conductive soil layers below the dry surface.

- Extensive Earthing Grids: Installing a large, interconnected grid of buried conductors to create a larger footprint for dissipation.

Core Components of a Lightning Protection System

| Component | Function | Common Materials | GCC-Specific Considerations |

|---|---|---|---|

| Air Terminals | Intercept lightning strikes at predetermined points. | Copper, Aluminum, Stainless Steel | Must withstand high UV exposure, heat, and sand abrasion. Placement is critical on complex, modern architectural designs. |

| Down Conductors | Provide a safe path for the lightning current from air terminals to the ground. | Copper, Aluminum | Routing must account for aesthetic integration on glass-clad buildings. Secure fastening is vital to resist thermal expansion/contraction. |

| Earth Termination System | Safely dissipate the electrical charge into the earth. | Copper-clad Steel Rods, Copper Tape | Requires engineering to overcome high soil resistivity (e.g., using GEMs, deep-driven rods, or extensive grids). Regular testing is crucial. |

Regular testing is vital to ensure the system remains effective. To learn more about the tools and techniques involved, review our guide on choosing an Earth Ground Tester for your projects.

When these three pillars are correctly designed and installed, they form a complete, robust defense against lightning.

Getting to Grips with IEC 62305 for Compliance in the UAE

For engineers, panel builders, and electricians working on major projects in the UAE and GCC, IEC 62305 is the definitive standard for designing and installing lightning protection systems. It is a structured, risk-based framework designed to protect people, buildings, and critical operations.

Following this standard is not just about compliance; it is the only way to ensure your system can withstand the immense power of a lightning strike. The standard mandates a complete risk assessment process, which is vital for projects ranging from complex industrial plants in Abu Dhabi to the iconic skyscrapers of Dubai.

The Four Parts of IEC 62305

The standard is divided into four parts, each addressing a specific aspect of protection. Together, they provide a complete roadmap from initial risk analysis to long-term maintenance.

- Part 1: General Principles. This foundational part explains the sources of lightning damage and introduces the concept of Lightning Protection Levels (LPL).

- Part 2: Risk Management. This section provides a clear methodology to calculate the actual risk to a structure, which determines the required level of protection.

- Part 3: Physical Damage to Structures and Life Hazard. This part details the external LPS components—air terminals, down conductors, and earthing systems.

- Part 4: Electrical and Electronic Systems within Structures. This critical section focuses on shielding internal systems from electrical surges using Surge Protection Devices (SPDs).

These parts are interconnected. The risk assessment from Part 2 directly informs the design of the physical systems in Part 3 and the surge protection measures in Part 4.

Figuring Out the Right Lightning Protection Level

The IEC 62305 approach hinges on a risk assessment that determines the required Lightning Protection Level (LPL). There are four levels, with LPL I being the most stringent and LPL IV the most basic. The LPL is calculated based on factors like:

- The building’s height and location

- Local lightning frequency

- Construction materials

- The value and sensitivity of internal equipment

- The potential risk to human life

For example, a hospital or a data center in a storm-prone area will almost certainly require an LPL I system, which involves a denser grid of air terminals and more down conductors than a simple storage warehouse that might only need an LPL IV setup. The LPL directly shapes every aspect of the system design.

Once the LPL is determined, the standard provides clear guidelines for the physical system.

| Lightning Protection Level (LPL) | Rolling Sphere Radius | Air-Termination Mesh Size | Down-Conductor Spacing |

|---|---|---|---|

| I (Highest) | 20 meters | 5m x 5m | 10 meters |

| II | 30 meters | 10m x 10m | 10 meters |

| III | 45 meters | 15m x 15m | 15 meters |

| IV (Lowest) | 60 meters | 20m x 20m | 20 meters |

A higher LPL (I or II) requires a tighter protection mesh and more down conductors, creating a more robust Faraday cage. This prescriptive method removes guesswork and ensures the system is matched to the real-world risk. For more insights, our guide to electrical risk management offers practical strategies.

By systematically applying the IEC 62305 framework, engineers in the UAE can deliver lightning protection systems that are not only compliant but genuinely effective.

Protecting Electronics From Indirect Lightning Strikes

A structural lightning protection system is a vital first defense, but it only solves half the problem. A common oversight is assuming that if lightning doesn't physically strike the building, assets are safe. In the highly interconnected industrial facilities across the UAE, this is a costly mistake.

An indirect strike—hitting the ground or a utility line kilometers away—can be just as devastating. It creates a massive electromagnetic field that induces powerful surges into nearby conductive paths. These surges race along power lines and data cables, seeking the quickest path to ground, often through your most sensitive equipment.

In a split second, these surges can destroy control panels, PLCs, VFDs, and critical monitoring systems, resulting in immediate downtime and high replacement costs. This is why a complete protection strategy must include Surge Protection Devices (SPDs).

The Coordinated SPD Strategy

Effective surge protection is a layered defense system, as outlined in IEC 62305-4. It uses different types of SPDs at strategic points to progressively clamp down on surge voltages.

Type 1 SPDs (The Front Gate): Installed at the main distribution board (MDB), these heavy-duty devices handle the colossal energy from a direct or very close lightning strike, diverting the majority of the surge current safely to earth.

Type 2 SPDs (The Internal Guards): Placed in sub-distribution boards (SDBs), these are the second line of defense. They protect against residual surges and those generated within the facility, essential for protecting circuits feeding control rooms or server racks in facilities from Dubai to Abu Dhabi.

Type 3 SPDs (The Final Defence): These point-of-use devices are installed next to the most sensitive equipment, like a PLC or server. They clean up any tiny residual voltage transients, ensuring complete shielding.

A coordinated approach is non-negotiable. Without a Type 1 SPD at the service entrance, a powerful surge will simply overwhelm and destroy downstream Type 2 and 3 devices. Each layer relies on the one before it to function correctly.

A Real-World GCC Scenario

Imagine a large industrial plant in a free zone like JAFZA. A lightning strike hits a utility pole a kilometer away. Without SPDs, the resulting surge travels down power lines, bypasses the main breaker, and slams into the MDB.

From there, it spreads through the facility's network, destroying VFDs, frying PLCs, and taking the entire Building Management System (BMS) offline. The financial fallout is catastrophic—not just from replacement costs but from weeks of lost production.

This scenario is preventable. With a proper SPD strategy, the Type 1 device would divert over 90% of the surge energy. Type 2 devices would handle the rest, and Type 3s would ensure the voltage reaching critical equipment remains within safe limits.

Learn more in our detailed guide to electrical surge protection. The cost of SPDs is a fraction of the potential loss.

Your Partner for Complete System Integrity

Proper lightning protection is a multi-layered strategy. First, the external lightning protection system handles the energy of a direct strike. Second, a coordinated internal defense of Surge Protection Devices (SPDs) shields sensitive electronics.

This entire setup must be engineered according to rigorous IEC 62305 standards to ensure genuine safety. Navigating these requirements demands a partner who understands the technical details and provides the full range of certified components. That’s where GoSwitchgear comes in. For professionals across the UAE and GCC, we are the central resource for every layer of your protection strategy.

Your Local Procurement and Support Hub

Projects in this region face unique challenges, from harsh environmental conditions to specific local regulations. Our role extends beyond supplying parts; we provide the hands-on technical support and logistical expertise that engineers, panel builders, and procurement teams in Dubai and Abu Dhabi rely on.

By sourcing all your components through GoSwitchgear, you streamline your project, ensure component compatibility, and gain a partner invested in the long-term integrity of your facility's protection.

For expert advice on specifying components or to request a quote for an upcoming installation in the UAE, contact our team. Let’s work together to build a comprehensive defense against lightning.

Frequently Asked Questions About Lightning Protection

Engineers, facility managers, and procurement teams across the UAE and GCC often have practical questions about specifying and maintaining lightning protection systems. Clear answers are crucial for compliance and safety in our demanding environment.

What Is the Difference Between a Lightning Rod and a Full System?

A single lightning rod (air terminal) is just one component, not a complete solution. On its own, it can be ineffective and even dangerous.

A complete lightning protection system is an engineered network of three parts working in harmony:

- Air Terminals: To safely intercept the strike.

- Down Conductors: To provide a safe path for the current to the ground.

- An Earth Termination System: To dissipate the energy harmlessly into the earth.

A complete, properly designed system is non-negotiable for any high-rise in Dubai or industrial plant in Saudi Arabia.

How Often Should We Inspect Our System in the UAE?

IEC 62305 recommends a visual inspection and a full electrical test every 12 months. However, due to the harsh local conditions in the GCC—intense heat, humidity, and dust—we advise a more proactive schedule. Best practice includes a visual check every 6 months, especially after a major storm or roof work. This can identify issues like corroded connections or loose conductors early. The annual electrical test remains essential to verify grounding network continuity and resistance.

Are Surge Protection Devices Really Necessary?

Yes, absolutely. A structural lightning protection system protects the building from physical damage but does not protect your sensitive electronics from the powerful electrical surges that accompany a strike.

A nearby lightning strike can induce a massive surge through power and data lines, destroying control panels, PLCs, and servers.

Surge Protection Devices (SPDs) are your indispensable second layer of defense. They are the guardians of your internal electrical systems, clamping down on transient overvoltages before they cause expensive damage and crippling downtime. Skipping SPDs leaves your most valuable assets completely exposed.

Can a Lightning Protection System Prevent a Strike?

No. A standard lightning protection system designed to IEC 62305 cannot prevent lightning from striking. Its purpose is to intercept a strike that is already going to occur and provide it with a safe, low-resistance path to the ground. It’s about controlling where the lightning hits and safely dissipating its energy to protect the structure and its occupants. The goal is management, not prevention.

For all your project needs, from certified air terminals to the latest SPDs, GoSwitchgear has you covered. Our teams in Dubai and Abu Dhabi are ready to support your next installation with a complete inventory of certified components.

Explore our full range of electrical solutions at https://goswitchgear.ae.

Leave a Reply