A Practical Guide to Lock Out Tags for Industrial Safety in the UAE

In high-risk industrial environments, like those across the UAE and GCC, preventing a machine from unexpectedly starting up isn't just a guideline—it's a life-or-death necessity. This is where lock out tags become absolutely crucial. Think of them as the ultimate non-verbal safety communicators, clearly broadcasting that a piece of equipment is powered down for maintenance and must not be touched. This guide offers practical insights for engineers, panel builders, and procurement teams on selecting and implementing these vital electrical components in the UAE.

Why Lock Out Tags Are Essential for Workplace Safety

In the demanding industrial hubs of Dubai, Abu Dhabi, and the wider GCC, the sudden release of hazardous energy can have catastrophic results. A proper Lock Out Tag Out (LOTO) program is the definitive procedure designed to stop that from ever happening during service or maintenance work. At the very heart of this program, you'll find lock out tags—simple, yet incredibly powerful tools that form the backbone of a safe work environment and a robust energy management solution.

A lock out tag is the final, crystal-clear instruction in a chain of safety commands. While a physical lock provides the "can't," the tag provides the critical "why." It tells anyone who approaches exactly who secured the equipment, why it's offline, and maybe even when it’s expected to be back up and running. For electricians, engineers, and maintenance crews working with complex machinery and switchgear, this visible warning system is absolutely indispensable.

The Core Purpose of a Lock Out Tag

The primary jobs of a LOTO tag are straightforward, but they are completely non-negotiable for keeping your people safe and your operations intact.

- To Warn and Inform: Its most vital role is to be a bright, unmissable warning that a machine is de-energized and being worked on. This is what stops a well-meaning colleague from accidentally starting it up, unaware of the work in progress.

- To Identify and Authorize: Every tag clearly names the authorized employee who placed the lock. This creates a direct line of accountability, making sure only that specific person can remove the safety measures once the job is finished safely.

- To Comply with Regulations: Using a standardized LOTO system, which includes the right tags, is a core requirement for meeting both local UAE and international safety standards. Proper implementation helps facilities in the UAE and KSA sidestep regulatory penalties and build a true culture of safety.

This principle of controlling access to prevent harm isn't just for physical equipment. Just as lock out tags are vital for securing machinery, sophisticated security protocols are essential in the digital world. This includes establishing clear access controls and using advanced tools like specialized Privileged Access Management systems to ensure only authorized personnel can get to critical digital assets.

Navigating LOTO Compliance and Regulations in the UAE

To build a Lock Out Tag Out (LOTO) program that actually works, you have to start with the local regulatory landscape. For any facility manager or electrical contractor in the UAE and GCC, getting a handle on these legal requirements isn't just about ticking boxes to avoid fines. It's about fundamentally making the workplace safer for everyone who steps foot on site. The standards set by local authorities are the bedrock of any LOTO system worth its salt.

These regulations give us a clear framework for everything, from how we train our people to the specific materials used for lock out tags. They create a level of consistency and reliability that is absolutely critical in high-risk environments, especially around electrical switchgear. Following these rules isn't optional; it's a core responsibility that protects both your team and your expensive equipment from disaster.

The results speak for themselves. The push for structured lockout-tagout systems in the UAE's electrical sector has seriously cut down on accident rates, making it an indispensable tool for switchgear manufacturers and system integrators. In the UAE alone, recent stats show that proper LOTO protocols prevented around 450 electrical shock incidents in the manufacturing and energy sectors. That's a massive 42% drop from the 780 cases that were recorded before these rules were widely enforced. This progress is right in line with the UAE's broader industrial safety goals, with some Abu Dhabi facilities hitting 98% LOTO compliance in audits, leading to a major reduction in penalty fines.

Key Compliance Pillars for LOTO in the UAE

A truly effective LOTO program in the UAE is built on a few non-negotiable pillars. Think of them as legs on a stool—if one is weak, the whole thing comes crashing down. These components work in harmony to create a comprehensive safety net, making sure every single procedure is done right, every single time.

You'll want to focus your energy on three critical areas:

- Mandatory Employee Training: Your authorized employees need to be experts at spotting hazardous energy sources and knowing the exact procedures to isolate and control them. This isn't a one-and-done training session; it demands regular refreshers to keep skills sharp.

- Comprehensive Documentation: Every LOTO procedure needs to be written down, period. This includes the specific, step-by-step instructions for shutting down, isolating, blocking, and securing equipment to keep hazardous energy under control.

- Periodic Audits and Inspections: Regulations require you to inspect your LOTO procedures at least once a year. These audits are your chance to find gaps, see what's working, and make continuous improvements before an incident occurs.

Nailing these pillars not only prevents accidents but also boosts your operational uptime by making maintenance workflows predictable and safe. To get the full picture, it's also smart to stay current with broader OSHA guidelines for workplace safety.

Local Mandates and Their Daily Impact

Here in the UAE, authorities like the Dubai Municipality and the Abu Dhabi Occupational Safety and Health Center (OSHAD) issue specific guidance that directly impacts day-to-day work. Their mandates often get very specific, detailing requirements for the durability, standardization, and legibility of lock out tags to make sure they can survive our harsh climate of extreme heat and humidity.

What does this mean for panel builders and electricians on the ground? It means you have to source tags and devices that are built to meet these tough local standards. For instance, tags might need to be bilingual (Arabic and English) to ensure everyone in a diverse workforce understands the warning. Procurement teams have to be on the ball, verifying that all LOTO gear, especially lock out tags, meets these regional specs to stay compliant.

A compliant LOTO program is a living system. It requires consistent training, diligent record-keeping, and regular reviews to remain effective. It is an investment in safety that pays dividends by preventing incidents and fostering a proactive safety culture.

Cutting corners on these standards can result in hefty penalties, project delays, and—worst of all—a much higher risk of someone getting seriously hurt. By partnering with a knowledgeable supplier like GoSwitchgear, you can rest easy knowing your LOTO components are fully compliant with all local rules. It reinforces your commitment to safety and gives you genuine peace of mind. We also offer deep-dive resources, like our detailed electrical safety course, to get your team trained up and ready.

How to Select the Right Lock Out Tags for Your Environment

Picking the right lock out tags isn’t a one-size-fits-all task, especially when you’re dealing with the tough industrial environments here in the UAE and across the GCC. A tag that looks perfectly fine indoors can quickly become unreadable or fall apart when exposed to direct sun or high humidity. This guide is for the engineers, panel builders, and procurement teams in places like Dubai and Abu Dhabi who need to make smart choices that keep people safe and the site compliant.

The process goes way beyond just grabbing a tag that says "DANGER." It’s about really thinking through where the tag will be used, what it needs to communicate, and how it will hold up. When you get this right, you can be confident that every tag will stay put and stay legible for the entire job, doing its part in your LOTO procedure.

Matching Tag Materials to GCC Conditions

The material a lock out tag is made from is its first defense against the environment. In a region that throws extreme heat, dust, and humidity at your equipment, choosing a tough-as-nails material isn't just a good idea—it's essential. The wrong tag can fade, tear, or completely disintegrate, turning a safety measure into a serious hazard.

Here’s a look at common materials and how they stack up in our local conditions:

- Heavy-Duty Vinyl (PVC): This is a solid, cost-effective workhorse for most indoor and some outdoor spots. It handles moisture, grease, and many chemicals well, making it a dependable option for factory floors and enclosed panel rooms.

- Polyester Laminate: When you absolutely can't compromise on durability, polyester is the way to go. These tags are incredibly resistant to tearing, harsh chemicals, and the relentless UV exposure of our climate. For any equipment sitting out in the UAE sun, a laminated polyester tag will outlast a vinyl one every time.

- Aluminium: For the most punishing industrial settings—think high heat or abrasive conditions—aluminium tags offer the ultimate in durability. They're completely weatherproof and can take a physical hit without compromising the safety message.

A crucial tip: Always check the manufacturer's temperature rating. A tag rated for up to 80°C is built for a sun-baked isolator in the GCC, unlike a standard one that might warp or fade. It's a small detail that makes a world of difference in reliability.

Before we move on, let's put these materials head-to-head in a simple table to make the choice even clearer for our specific regional challenges.

Comparing Lock Out Tag Materials for GCC Environments

This table breaks down the most common lock out tag materials, comparing their durability, resistance to industrial hazards, and overall cost-effectiveness for the demanding climate of the UAE and the wider GCC region.

| Material Type | Durability & Heat Resistance | Chemical & UV Resistance | Ideal Application Environment | Cost-Effectiveness |

|---|---|---|---|---|

| Heavy-Duty Vinyl (PVC) | Good for moderate heat; can become brittle in extreme sun. | Good resistance to moisture, grease, and common chemicals. | Best for indoor or shaded outdoor areas like factory floors and covered machinery. | Most budget-friendly option for general use. |

| Polyester Laminate | Excellent; withstands high temperatures and resists tearing. | Superior resistance to harsh chemicals and long-term UV exposure. | Perfect for outdoor equipment, solar farms, and chemical processing plants. | Higher initial cost but offers the best long-term value in harsh conditions. |

| Aluminium | Maximum durability; withstands extreme heat and physical impact. | Completely weatherproof and resistant to most industrial chemicals. | Ideal for heavy industrial settings, offshore rigs, and high-temperature machinery. | Highest cost, but justified for the most extreme environments where others fail. |

As you can see, the environment dictates the material. Matching the tag to its future home is the first step toward a bulletproof LOTO system.

Tailoring Tag Design for Specific Applications

Once you’ve nailed down the right material, the next step is making sure the tag’s design and message are crystal clear for its specific job. The information on that tag needs to be understood instantly by anyone who walks up to the equipment.

Think about these customization options to boost clarity and compliance:

- Bilingual Text: With the diverse workforce in the GCC, having warnings in both English and Arabic is a critical best practice. It dramatically improves understanding and safety for everyone on site.

- Pre-Printed vs. Write-On Fields: Your tags must have clean, dedicated spaces for the employee's name, department, date, and why the equipment is locked out. For routine jobs, pre-printing specific hazards like "High Voltage" or "Do Not Close Valve" adds immediate, crucial context.

- Company Branding and Colour Coding: Adding your company logo isn't just for looks; it reinforces the official nature of the procedure. You can also use a color-coded system—maybe red for electrical hazards and blue for mechanical—to help technicians identify the danger at a glance.

Finally, how the tag is attached is just as important as the tag itself. Look for a strong nylon or metal grommet that stops the tie-hole from ripping, a very common failure point. When you pair that with a sturdy, self-locking nylon tie, you ensure the tag stays firmly attached to the lockout device, like an isolator switch, throughout the entire maintenance task. If you're looking for more on choosing the right hardware, our guide on selecting an isolator switch from ABB offers some great technical advice.

Choosing the right lock out tags is a cornerstone of any effective LOTO program. By thinking through the material, customizing the message for total clarity, and using a secure attachment, you’ll significantly strengthen your safety protocols and, most importantly, protect your team.

A Step-by-Step Guide to Implementing LOTO Procedures

A solid Lock Out Tag Out (LOTO) program is all about having a clear, repeatable process that everyone on the floor can understand and follow. Getting from the safety manual to the real world requires a structured approach that leaves zero room for error. Let's walk through the entire process, from prep to sign-off, turning best practices into second nature for engineers and electricians across the UAE.

Think of the LOTO process as a safety chain. Every single link has to be strong and executed in the right order. One weak link, and the whole procedure can fail, leading to disaster.

Phase 1: Preparation and Notification

Before anyone even thinks about picking up a tool, the first step is solid preparation. The authorised employee—the person actually doing the maintenance—needs to investigate and get a complete handle on every hazardous energy source connected to the equipment. We're not just talking about the main electrical feed. This includes stored energy like compressed air, hydraulic pressure, or even the simple force of gravity.

Once all the hazards are mapped out, the next move is all about communication. The authorised employee has to let all affected employees know what's happening. These are the machine operators or anyone working nearby who needs to be aware that the equipment is being shut down for service. This simple heads-up prevents confusion and stops a well-meaning colleague from trying to fire up the machine while it’s being worked on.

This initial phase is crucial. It ensures the person doing the work knows all the risks, and everyone in the area is aware of the shutdown.

Phase 2: Shutdown and Isolation

With the plan in place and everyone notified, it's time for the shutdown. The equipment has to be turned off using its normal operating controls. This makes for an orderly shutdown and avoids the kind of surprises you might get from just yanking the main breaker. It's a controlled, predictable first step in the de-energization process.

After the shutdown, the equipment has to be completely cut off from its energy sources. This is the absolute core of the LOTO procedure—physically disconnecting the machinery from its power.

During this phase, you'll be:

- Opening a main circuit breaker or isolator switch.

- Closing a valve to cut off the flow of fluids or gases.

- Disconnecting any lines or pipes that are supplying energy.

This creates a real, physical barrier between the equipment and its power, making it impossible for energy to reach the machine while you're working.

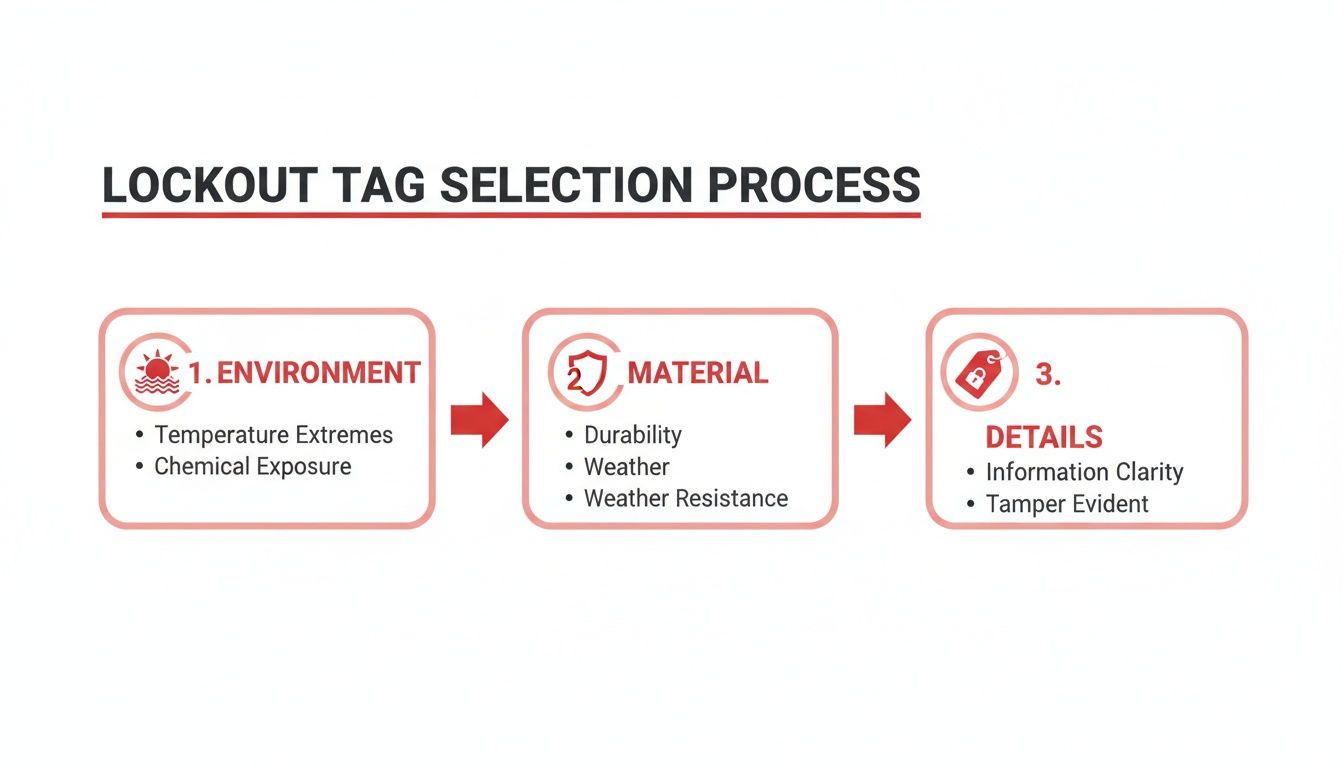

This infographic is a great visual guide for picking the right lock out tags for the job, which is a key part of this isolation phase.

Moving from assessing the environment to choosing the right material and tag details ensures every tag is up to the task, especially in the tough climates we see across the GCC.

Phase 3: Application and Verification

Once the equipment is isolated, the authorised employee puts on the lockout device and the lock out tag. The lock physically stops the energy-isolating device from being switched back on. The tag, meanwhile, clearly communicates who locked it out and why.

Verification is the most frequently overlooked yet most critical step in the entire LOTO procedure. It is the final confirmation that all hazardous energy has been successfully controlled and the equipment is truly safe to work on.

After applying the lock and tag, the authorised employee must try to start the equipment using its normal controls. This is the "try" step. Pushing the start button or flipping a switch should do absolutely nothing. This action verifies that the isolation worked and the machine is completely dead.

Finally, you have to check for any leftover energy. This could mean bleeding hydraulic lines, discharging capacitors, or blocking elevated parts that could fall due to gravity. Never assume a machine is safe just because the main power is off. This final check is your guarantee that you've achieved a true zero-energy state.

Integrating Tags with a Complete LOTO System

A lock out tag is a powerful visual warning, but it's critical to understand that it doesn't do the job alone. It’s just one piece of a much larger safety puzzle. True protection from hazardous energy release only happens when tags, physical lockout devices, and solid procedures all work together seamlessly.

This integrated system is what turns a simple warning into a verifiable safety barrier. For engineers and electricians working on complex switchgear in Dubai or Abu Dhabi, this isn't just best practice—it's non-negotiable. The tag explains the why and the who, while the lock provides the cannot. Together, they create an unmistakable state of safety.

The Tag and Lock Partnership

At its heart, a Lock Out Tag Out (LOTO) system is a partnership. The tag handles the communication, and the lock provides the physical prevention. If you have one without the other, you’ve got a massive gap in your safety protocol. That's why the tag is always attached to a lockout device, never directly to the equipment itself.

Some of the most common lockout devices you'll see working hand-in-hand with lock out tags include:

- Safety Padlocks: The backbone of most LOTO programs. These are individually keyed to a single authorized employee, making sure only that person can remove it.

- Circuit Breaker Lockouts: These clamp directly onto a circuit breaker's switch, making it physically impossible to flip it back on. The padlock and tag are then secured to this device.

- Valve Lockouts: Used to isolate pneumatic or hydraulic energy, these devices fit over valve handles to stop them from being turned.

- Hasps: Ever see multiple locks on one piece of equipment? That’s a hasp at work. When several technicians are on the same job, each one attaches their own padlock and tag to the hasp. The machine can't be re-energized until the very last person has finished and removed their lock.

This combination creates a barrier that is both physically tough and information-rich, leaving zero room for guesswork on the facility floor.

Think of it like a bank vault. The thick steel door is the physical lockout device—it's an impenetrable barrier. The sign on the door explaining it's time-locked until 9 AM is the lock out tag—it provides the critical context. You absolutely need both for real security.

In the fast-paced industrial world of the UAE, especially in sectors like oil and gas, LOTO procedures are a cornerstone of safety. In recent years, UAE industrial facilities reported over 1,200 LOTO-related safety audits, which led to a 28% drop in energy isolation incidents. Facility managers also found that proper LOTO implementation cut maintenance downtime by 35%, leading to faster project turnarounds. You can dig into more of these findings over at DataInsightsMarket.com.

Handling Complex Scenarios with Group Lockouts

Sometimes, a single maintenance job needs a whole team—electricians, mechanics, technicians—all working on the same machine at once. A simple one-person, one-lock system just won't cut it. That's where a group lockout procedure, managed with a lockout box, is essential.

The process is brilliantly simple and highly effective:

- Initial Isolation: A lead authorized person, usually a supervisor, applies a single primary lock to the main energy source. They then place the key to that lock inside the group lockout box.

- Individual Lock Application: Next, every single member of the maintenance team attaches their personal padlock and lock out tag to the outside of the group box.

- Ensuring Total Safety: The equipment is now completely de-energized because the key to the main lock is trapped inside the box. It cannot be restarted until every single team member has finished their work and personally removed their own lock.

This method creates a clear, verifiable system that protects every single worker. It guarantees that no one individual can re-energize the equipment while others are still in a dangerous position, making it a critical practice for large-scale maintenance projects across the GCC's industrial sector. After all, true safety is always a collective effort.

Maintaining and Auditing Your LOTO Program

Putting a Lock Out Tag Out (LOTO) program in place is a massive win for workplace safety, but it's just the starting line, not the finish. In the tough industrial environments you find across the UAE, keeping your team safe long-term comes down to diligent, consistent upkeep and auditing of the entire system. Without it, procedures get stale, equipment fails, and the program's effectiveness slowly bleeds out.

Think of it like regular car maintenance. You wouldn't just skip an oil change and expect your engine to keep running smoothly, right? Your LOTO program needs the same kind of regular check-up to make sure every single part, especially the highly visible lock out tags, is working correctly and meeting the strict safety standards required in the GCC. This isn't just about ticking boxes; it's about embedding a real, living culture of safety.

Conducting Periodic Inspections

Regular inspections are the bedrock of any healthy LOTO program. This is way more than a quick glance around the facility. It's a systematic review of all your physical LOTO gear and a reality check on whether your team is actually following the procedures. These checks need to be scheduled, carried out, and documented so nothing ever falls through the cracks.

A solid, straightforward inspection routine should cover:

- Tag Legibility: Grab the lock out tags currently in use and the spares in storage. In this region's harsh sun and humidity, have they faded, cracked, or become impossible to read? A tag you can't read is a major failure waiting to happen.

- Device Functionality: Check all your lockout devices—the padlocks, hasps, breaker lockouts—for any signs of wear, corrosion, or damage. A lock that's about to fail is just as bad as having no lock at all.

- Procedure Accuracy: Your annual audit needs to confirm that the documented procedures for every piece of machinery are still correct. Has a new energy source been added? Did the shutdown sequence get an update?

- Employee Competency: Watch your authorized employees as they perform LOTO procedures. Are they hitting every single step, especially that crucial final verification stage? This is where theory meets practice.

The Importance of Meticulous Record-Keeping

Good documentation is your program’s memory. It’s also the engine for continuous improvement. This isn't just about having a paper trail for compliance; meticulous records are your best tool for spotting systemic weaknesses and proving you've done your due diligence.

Maintaining detailed records transforms your LOTO program from a static set of rules into a dynamic, learning system. Each audit, training session, and incident review provides valuable data to refine and strengthen your safety protocols.

Your record-keeping should be comprehensive, covering three key areas:

- Training Logs: Keep a detailed log of every employee's LOTO training. Note the dates, what topics were covered, and how they were assessed. This is your proof of competency.

- Audit Reports: Document everything from your annual LOTO procedure audits. Note any deviations found, the corrective actions taken, and who was responsible for the review.

- Incident Reviews: If a near-miss or an actual incident happens, a thorough, documented review is non-negotiable. This analysis is absolutely vital for digging into root causes and making sure it never happens again.

By consistently keeping up with maintenance and audits, you ensure your program stays robust, effective, and compliant. This ongoing effort is directly tied to the operational reliability of your entire facility. To get a better handle on structuring these efforts, check out our insights on planned preventative maintenance strategies.

Your Lock Out Tag Questions Answered

We get a lot of questions from engineers and facility managers across the UAE about the finer points of lockout-tagout. Let's clear up a few of the most common ones.

What's the Real Difference Between a Lock and a Tag?

Think of it this way: a padlock physically stops a machine from being turned on. It’s the brute force. A lock out tag, on the other hand, is the brain behind the brawn.

The tag is a critical communication device attached to that lock. It tells everyone passing by who locked out the equipment and, crucially, why it's out of service. You need both for a proper LOTO procedure. The lock is the physical barrier; the tag provides the essential warning and information.

How Often Should We Be Reviewing Our LOTO Procedures?

Best practice, which aligns with top international standards followed here in the GCC, is to conduct a formal review of your LOTO procedures at least once a year.

This isn't just a paper-pushing exercise. An annual audit confirms that your documented procedures are still accurate for the equipment you have and that your team is actually following them correctly. It’s how you keep the program effective and ensure it's genuinely protecting your people.

Can We Reuse Lock Out Tags?

That’s an emphatic no. Lock out tags are strictly single-use items and should never be reused for any reason.

Why? Reusing a tag is a recipe for disaster. It can easily lead to displaying old, inaccurate information, creating a massive safety risk on the floor. Once a job is done and the authorized person removes their tag, it needs to be disposed of immediately. This ensures every lockout starts with fresh, correct information.

Conclusion: Securing Your Operations in Dubai and Abu Dhabi

For engineers, electricians, and procurement teams in the UAE, implementing a robust LOTO system isn't just about compliance—it's about a fundamental commitment to safety and operational excellence. By carefully selecting lock out tags suited to the harsh GCC climate and integrating them into a comprehensive, well-audited procedure, you create a safer, more efficient work environment.

If you need project support or want to source high-quality, compliant electrical components in the UAE, reach out to our team. Contact us for a quote for your Dubai projects and let's build a safer workplace together.

Browse Our Full Range of Electrical Safety Components at GoSwitchgear

Leave a Reply