A Complete Guide to Floor Box Sockets for UAE Projects

In the architectural landscape of the UAE and wider GCC, where open-plan offices and vast public spaces are the norm, power solutions must be both ubiquitous and discreet. This is the precise challenge floor box sockets are engineered to solve. They deliver safe, concealed power and data connectivity exactly where needed, preserving aesthetic integrity and eliminating hazardous trip wires.

Simply put, they are a critical component for any modern, flexible building in the region.

Why Floor Box Sockets Are Essential for Modern GCC Buildings

Modern building design, particularly in dynamic cities like Dubai and Abu Dhabi, emphasizes clean lines, open layouts, and multi-purpose spaces. From high-tech boardrooms to sprawling airport lounges, the requirement for power and data has migrated from the walls to the centre of the room. This functional shift makes floor box sockets a non-negotiable element of any serious electrical infrastructure plan.

These integrated units eliminate the need for messy extension cords and unsightly cable runs. This is more than an aesthetic improvement; it's a significant safety enhancement, removing trip hazards while protecting the architect's original design intent. For instance, a well-designed office will almost always feature a conference table with electrical outlets supplied directly from floor boxes, ensuring operational efficiency and a professional appearance.

Meeting Regional Demands

The adoption of floor boxes is not merely a design trend but a fundamental requirement driven by the region's rapid growth. Across the UAE and the wider GCC, demand has escalated, fueled by massive construction projects linked to national strategies like Saudi Arabia's Vision 2030.

The scale is significant. Giga-projects in Saudi Arabia, including the futuristic city of NEOM, have necessitated electrical infrastructure upgrades requiring an estimated 500,000 advanced floor socket units. In the UAE, projects such as the Dubai Expo 2020 legacy sites contributed an additional 150,000 installations.

Addressing Unique Environmental Challenges

Beyond aesthetics and flexibility, floor boxes in the GCC must demonstrate exceptional resilience. They must withstand unique environmental challenges not found elsewhere, including persistent fine dust, high humidity, and the intensive floor cleaning protocols common in commercial facilities.

This makes selecting the correct floor box sockets with appropriate IP (Ingress Protection) ratings absolutely critical for long-term performance and safety.

A correctly specified floor box is the key to long-term reliability. It guards against dust and moisture, maintains system integrity, and ensures full compliance with local standards, protecting both the building's assets and its occupants.

This guide provides engineers, contractors, and procurement teams with practical, technically sound advice for selecting, installing, and maintaining these essential components for any project in the UAE and beyond.

Navigating the Different Types of Floor Box Sockets

Selecting the right floor box can seem complex, but the decision for any UAE-based project primarily depends on three factors: material composition, access mechanism, and the required power or data configurations.

Making an informed choice at the specification stage is an investment in long-term performance, safety, and a clean aesthetic that integrates seamlessly, whether in a bustling Dubai commercial hub or a corporate office in Riyadh. Let's dissect the options from a practical, on-site perspective.

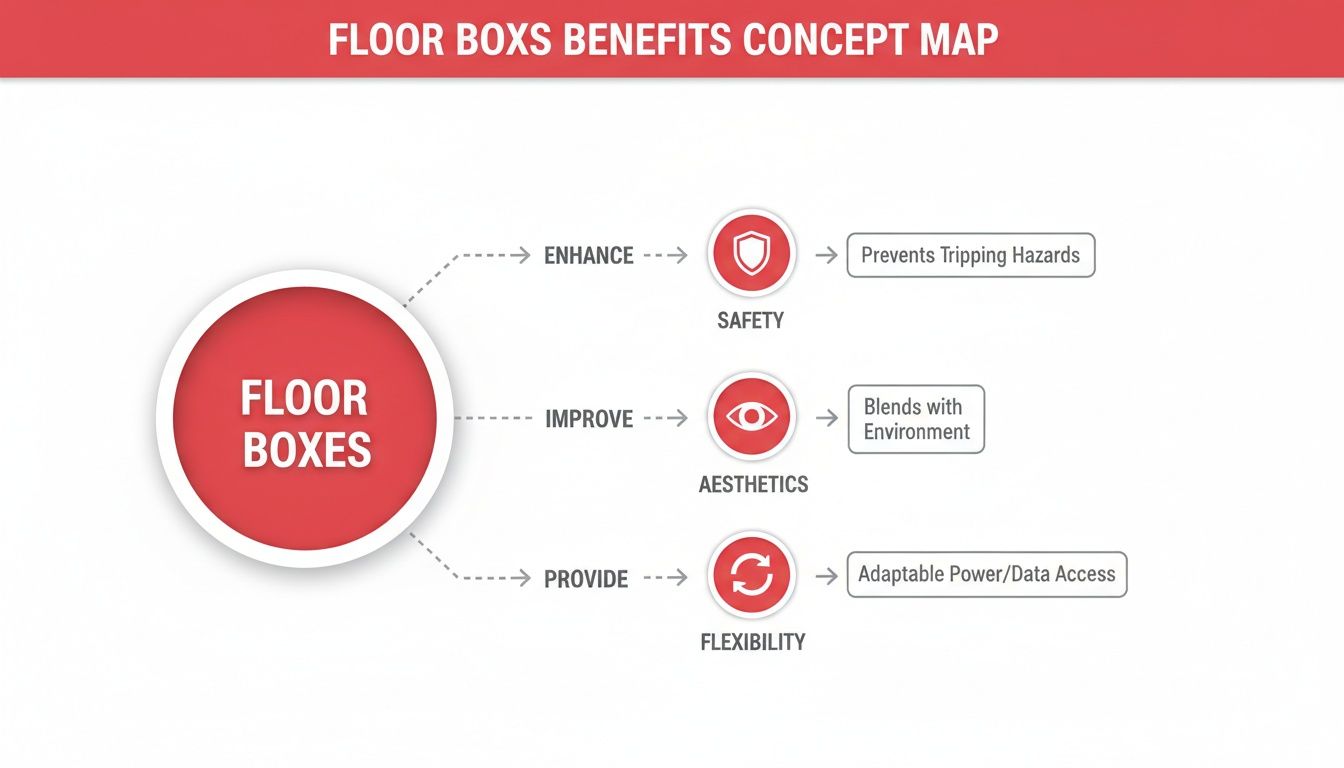

As illustrated, a well-chosen floor box delivers a tripartite advantage: it enhances safety, sharpens interior design, and provides flexible access to power and data precisely where it is most needed.

To simplify the selection process, the following comparison table outlines the most common types of floor box sockets encountered in the GCC market.

Comparison of Common Floor Box Socket Types

| Floor Box Type | Primary Material | Key Advantages | Best Suited For |

|---|---|---|---|

| Metallic Pop-Up | Brass, Stainless Steel | Aesthetically pleasing, flush finish, durable | Boardrooms, high-end retail, hotel lobbies, minimalist offices |

| Metallic Recessed | Stainless Steel, Aluminium | Excellent load-bearing, superior cable protection, safer when in use | Airports, convention centres, public areas, high-traffic zones |

| Non-Metallic Pop-Up | High-Impact PVC | Cost-effective, corrosion-resistant, discreet | Modern offices, residential spaces, areas with low to moderate footfall |

| Non-Metallic Recessed | Polycarbonate, PVC | Lightweight, easy to install, good cable management | General office spaces, classrooms, data centres |

This table provides a snapshot to guide initial specifications. By matching the material and access style to the operational environment, you ensure the floor box will perform reliably for years to come.

Metallic vs. Non-Metallic Materials

The initial decision concerns the material. This choice has a significant impact on durability, lifespan, and budget, especially considering the unique climate and high construction standards across the GCC.

Metallic Boxes (Stainless Steel, Brass, Aluminium): These are heavy-duty solutions specified for high-traffic environments like airport terminals, hotel lobbies, and convention centres in Abu Dhabi. Their primary advantage is exceptional durability and load-bearing capacity. Materials like brass and stainless steel also provide a premium aesthetic preferred by architects for high-end interiors. The trade-off is higher cost and the requirement for proper grounding during installation.

Non-Metallic Boxes (High-Impact PVC, Polycarbonate): These are the preferred choice for value and corrosion resistance. Ideal for modern offices and residential projects, they are lightweight, easier to install, and resistant to the high humidity prevalent in the UAE. While robust, they may not be suitable for areas with heavy trolleys or constant, heavy foot traffic unless specifically rated for such conditions.

Pop-Up vs. Recessed Access Styles

The next consideration is the user access mechanism, a decision balancing sleek design with everyday practicality.

The ideal access style is determined by two questions: How often will it be used, and how critical is a perfectly flat floor? Pop-up designs offer near-invisibility when closed, while recessed models prioritize cable management and safety during use.

Pop-Up Floor Boxes

These units sit completely flush with the floor. A button or latch is pressed, and the socket assembly rises elegantly for use.

- Pros: They are incredibly discreet. When closed, they leave a clean, uninterrupted floor surface, making them perfect for boardrooms, luxury retail, and minimalist spaces where aesthetics are paramount.

- Cons: The raised mechanism can present a greater trip hazard when open. Furthermore, the pop-up mechanism itself can be a point of failure if not sourced from a reputable, high-quality manufacturer.

Recessed Floor Boxes

In these models, a hinged or lift-off lid reveals sockets situated below floor level. A small flap in the lid allows cables to exit while the cover remains mostly closed.

- Pros: They offer superior cable management and protection for plugs. Because they maintain a lower profile when in use, they are significantly less of a trip hazard, making them a safer choice for busy public spaces.

- Cons: The lid and cable flap are always visible, which may not align with certain high-end interior design schemes.

Power, Data, and Hybrid Configurations

Finally, you must decide on the internal configuration. Modern floor box sockets are highly modular, allowing for a combination of services within a single unit to meet the precise needs of a space.

Common configurations for specification include:

- Duplex Power Outlets: The standard configuration, providing two 13A BS sockets for general power requirements.

- Data and AV Modules: Equipped to hold RJ45 data ports, HDMI, VGA, or USB connectors. These are essential for meeting rooms and presentation areas.

- Hybrid Units: The all-in-one solution, combining power sockets with data and AV modules in a single, organized unit. This is the default choice for modern conference rooms in hubs like Dubai's financial district, offering users seamless plug-and-play connectivity.

A critical note for hybrid units: always confirm proper internal segregation between power and data wiring. This is vital to prevent electromagnetic interference (EMI), which can degrade network speed and stability.

To see how these configurations come to life, explore the versatile range of floor socket boxes available on GoSwitchgear.

Decoding Technical Specifications for the GCC Climate

In the demanding commercial environments of the UAE and KSA, a generic datasheet is insufficient. The unique combination of intense heat, fine desert dust, high humidity, and aggressive cleaning protocols means the technical specifications of floor box sockets are not just numbers—they are critical indicators of safety, durability, and compliance.

Selecting a component based on price alone, without scrutinizing its technical resilience, is a formula for premature failure and costly replacements. For engineers and procurement teams in the GCC, understanding these specifications is the first line of defense against operational issues. Let's translate key technical data into practical, region-specific knowledge.

The Critical Importance of Ingress Protection (IP) Ratings

If you examine only one specification, make it the Ingress Protection or IP rating. This two-digit code, defined by international standard IEC 60529, is a direct measure of an enclosure's effectiveness in protecting internal electrical components from solids (like dust) and liquids (like water).

The first digit rates protection against solids (0 = no protection; 6 = completely dust-tight). The second digit rates protection against liquids (0 = no protection; 8 = continuous submersion).

In a region where fine desert dust is a constant and floor mopping is a daily ritual, the IP rating is non-negotiable. It’s the difference between a floor box that lasts for years and one that becomes a safety hazard within months.

For most commercial projects in Dubai or Abu Dhabi, specific ratings are required to handle the local environment:

- IP44: This is the minimum acceptable rating for general office spaces. It protects against objects larger than 1mm (first '4') and from water splashing from any direction (second '4'). This is sufficient for handling stray debris and routine floor mopping.

- IP65/IP66: These ratings represent a significant upgrade. The '6' indicates the unit is totally sealed against dust. The '5' or '6' signifies it can withstand powerful water jets, making it ideal for high-traffic public areas, atriums, or industrial zones with intensive cleaning.

- IP67: This specification means the floor box is not only dust-tight but can also withstand temporary submersion in up to 1 metre of water. While potentially excessive for a standard office, it is a prudent choice for outdoor terraces, poolside areas, or locations where accidental flooding is a possibility.

Electrical Ratings and Load-Bearing Capacity

Beyond environmental protection, a floor box must safely manage electrical and physical stresses. Here are the key specifications to verify:

Electrical Specifications

The standard for power sockets in the UAE is the 13A BS 1363 configuration. Ensure any floor box specified for a UAE project contains outlets compliant with this standard. The internal wiring and terminals must be rated to handle a continuous 13 Amp load at 230V/50Hz without overheating. For hybrid units with data ports like RJ45s, verify proper shielding to prevent electromagnetic interference (EMI) from adjacent power lines.

Load-Bearing Capacity

A floor box is an integral part of the floor and must withstand foot traffic, heavy cleaning machines, and service trolleys. This capacity is measured in kilograms (kg) or kilonewtons (kN). A standard office floor box should handle at least a 300 kg load. For high-traffic areas like airports, malls, or exhibition halls in the GCC, units rated for 1000 kg or more are necessary. Always confirm this value on the manufacturer’s datasheet.

Material Durability and Regional Compliance

The material of the floor box significantly impacts its lifespan and appearance, particularly in the humid and often corrosive coastal climate of the GCC.

- Stainless Steel (Grade 304 or 316): An excellent choice for pure durability and corrosion resistance, well-suited for high-end commercial spaces.

- Brass: Offers a premium, classic aesthetic but requires regular polishing to maintain its appearance.

- High-Impact Polycarbonate: A robust, cost-effective option with excellent corrosion resistance, ideal for modern office fit-outs.

Finally, compliance is mandatory. Any floor box sockets installed in the UAE or KSA must carry the necessary certifications. Look for markings indicating compliance with IEC standards (e.g., IEC 60670-23) and the G-Mark (GCC Conformity Mark). These certifications provide proof that the product has been tested for safety and performance—a critical requirement for project approval from local authorities like DEWA.

Installation Best Practices to Ensure Flawless Performance

A perfectly installed floor box socket is one that operates invisibly and reliably. For electricians and site engineers across the UAE, achieving this requires absolute precision from the project's outset. A flawless installation not only enhances aesthetics but also prevents future complications, guarantees safety, and preserves the integrity of the finished space.

This is a practical guide for executing floor box installations correctly the first time, covering everything from floor preparation to final commissioning, ensuring each unit is secure, compliant with local wiring regulations, and resilient enough for a busy GCC commercial environment.

Preparing the Floor and Cutout

The entire installation's success depends on a perfectly prepared opening, whether working with a new concrete slab or a raised access floor.

In concrete floors, planning must occur before the pour. A temporary former box, or "block-out," is positioned within the rebar to create the required void. It is critical that this former is perfectly level and securely anchored to prevent movement during the concrete pour.

For raised flooring systems, the cutout is made directly into the floor panel. The manufacturer's datasheet for the floor box socket will provide the exact cutout dimensions. Always measure twice; a deviation of a few millimetres can result in a loose and unstable box.

The single most common point of failure in a floor box installation is an improperly sized or finished cutout. Allocating extra time to achieve perfection here prevents significant rework and ensures the box sits absolutely flush and secure.

Ensuring Correct Depth and Alignment

Incorrect depth is another common error. The objective is for the lid or trim of the floor box to sit perfectly flush with the finished floor level, be it tile, carpet, or wood.

- Consider Floor Finishes: Always account for the thickness of the final floor covering. A box set too high creates an immediate trip hazard. One set too low creates an unsightly recess that accumulates dirt and complicates cleaning.

- Align with Trunking: The box must align perfectly with the underfloor trunking or conduit system. Verify that the knockout panels on the box are positioned for smooth, stress-free cable entry. Misalignment places strain on cables, potentially damaging their sheathing and complicating the wiring process.

Common Installation Mistakes to Avoid

In the fast-paced construction projects of Dubai and Abu Dhabi, avoiding a few common errors can distinguish a durable, professional installation from one requiring costly callbacks.

Mistake 1: Improper Sealing

Failing to seal the box correctly negates its IP rating. In the GCC, where dust and moisture from regular floor cleaning are constants, this is a critical flaw.

- Solution: Use the gaskets and seals provided with the box. When installing in a screed floor, ensure the screed is packed tightly against the box body, leaving no gaps. For areas subject to wet cleaning, apply a bead of a suitable waterproof sealant around the frame as a final, essential step.

Mistake 2: Forgetting Construction Phase Protection

During construction, an open floor box becomes a receptacle for debris, cement, paint, and water, which can jam mechanisms and damage electrical connections.

- Solution: Keep the protective cover in place for as long as possible. Quality floor boxes are typically shipped with a disposable temporary lid for this purpose. Do not remove it until the final cleaning phase just before project handover.

Mistake 3: Over-Tightening Fixings

Whether using clamp-fixes in a raised floor or screwing the box into a concrete base, excessive torque can warp the frame or strip the threads. A warped frame will prevent the lid from closing properly.

- Solution: Tighten fixings until they are snug and secure, but do not overtighten. Once fixed, open and close the lid several times to ensure smooth movement, confirming the frame is not distorted. This simple check can prevent significant issues.

A Practical Maintenance Guide for Facility Managers

Following project handover, the day-to-day reliability of a building's floor box sockets falls to the facility management team. In the high-traffic commercial spaces common across the UAE, a "fit and forget" approach is not viable.

A straightforward, proactive maintenance strategy distinguishes a system that provides years of reliable service from one that causes persistent operational disruptions. It is about ensuring user safety, preventing costly emergency repairs, and maintaining seamless functionality. This guide is tailored to the real-world conditions of Dubai and Abu Dhabi, focusing on mitigating dust ingress and ensuring flawless operation.

Developing a Routine Maintenance Schedule

Consistency is paramount. A simple, scheduled plan enables your team to identify minor signs of wear and tear long before they escalate into major failures.

In the dusty climate of the GCC, a quarterly inspection for floor boxes in high-traffic areas is your best defense. This simple check can prevent over 90% of common problems, such as jammed pop-up mechanisms or poor electrical connections. It maintains the floor box as a safe, dependable asset rather than a hidden liability.

Here is a practical quarterly checklist for maintenance teams:

- Visual Inspection: Conduct a visual check of the lid, frame, and sockets for any obvious damage, such as cracks in plastic components or warping of metal frames, which could compromise strength or the IP rating.

- Mechanism Test: For pop-up models, operate the mechanism several times. The movement should be smooth, not sticky or stiff. Resistance indicates dust and grit accumulation.

- Seal Integrity Check: Closely inspect the gaskets and seals around the lid. In the UAE, where daily floor cleaning is common, these seals are vital for preventing moisture ingress. They should be flexible and intact, with no signs of cracking or deterioration.

- Secure Fastenings: Gently attempt to move the box. If it rocks or shifts, the fixings have loosened and require immediate tightening to prevent damage to the unit and the surrounding floor.

Cleaning Techniques for the GCC Environment

The fine dust prevalent in the region presents a unique challenge. Standard cleaning methods can push this dust deeper into moving parts, exacerbating problems.

Safe and Effective Cleaning Steps

- Isolate Power: Safety is the first priority. De-energize the circuit at the breaker before any maintenance begins. This is non-negotiable.

- Use Compressed Air: A can of compressed air is the most effective tool. Use short bursts to clear dust from the pop-up mechanism, hinges, and areas around socket outlets.

- Wipe with a Damp Cloth: Use a slightly damp, lint-free cloth to wipe all surfaces, internal and external. Never spray cleaning fluids directly into the box, as this can lead to moisture ingress and short circuits.

- Final Inspection: Once clean and completely dry, perform a final function test before re-energizing the circuit.

Troubleshooting Common Floor Box Issues

Even with a robust maintenance plan, issues can arise. This quick guide will help your team diagnose and resolve the most common problems efficiently.

| Issue | Possible Cause | Solution |

|---|---|---|

| Pop-up mechanism is stuck | Dust or debris has entered the latch mechanism. | Use compressed air to clear the obstruction. If stiffness persists, a minimal amount of silicone-based lubricant can be applied. |

| Lid does not close flush | An oversized plug is in use, or a cable is pinched in the hinge. | Ensure only standard-sized plugs are used. Check for trapped cables preventing the lid from closing properly. |

| No power from the socket | The circuit breaker has tripped, or there is a loose internal connection. | Always check the breaker panel first. If the breaker is not tripped, a qualified electrician must inspect the internal wiring for loose terminals. |

Your Essential Procurement Checklist for UAE Projects

Procuring the correct floor box sockets is the final, critical step in ensuring your project's electrical infrastructure is safe, compliant, and durable. A minor oversight at this stage can lead to expensive delays, significant installation challenges, and premature component failure.

This checklist serves as a final quality assurance tool for engineers and purchasing teams across the UAE. Before approving the next order for a project in Dubai or Abu Dhabi, review these points to guarantee that the sourced components are perfectly matched to the project's demanding environment.

Power and Data Requirements

First, define the specific functional needs of each location. Will a simple duplex power outlet suffice, or does the space require a hybrid unit with integrated data and AV ports?

- Power Sockets: Always verify that every outlet conforms to the 13A BS 1363 standard. This is mandatory for the UAE.

- Data/AV Modules: Be specific. List the exact modules required (e.g., RJ45, USB-A/C, HDMI). Critically, ensure the chosen floor box provides proper segregation between power and data lines to prevent electromagnetic interference (EMI).

- Future Proofing: Consider specifying boxes with one or two empty module slots. This provides the flexibility to accommodate future technology upgrades without replacing the entire unit.

Environmental and Durability Checks

The GCC climate is harsh on materials. The selected floor box must be engineered to withstand its specific environment, from the flooring type to the daily cleaning regimen.

An incorrect IP rating or material choice is not a minor mistake—it is a direct threat to the installation's longevity and safety. For any UAE-based project, this is the single most critical technical specification to verify.

- IP Rating: For a standard office with regular mopping, specify a minimum of IP44. For high-traffic public areas like malls or airports, or zones with more intensive wet cleaning, upgrade to IP65 or higher for complete protection against dust and water jets.

- Material: Match the material to the setting. For high-end aesthetics and maximum durability, stainless steel or brass are the optimal choices. For standard commercial fit-outs requiring good corrosion resistance, specify high-impact polycarbonate.

- Load Bearing: Confirm the load rating can handle the site's demands. A minimum of 300 kg is required for typical office environments, increasing to over 1000 kg for busy public spaces.

Compliance and Dimensional Verification

Finally, ensure the physical product is fully compliant and will fit perfectly on site, eliminating any surprises during installation.

- Certifications: Check the product datasheet for mandatory IEC standards and, crucially, the GCC Conformity Mark (G-Mark). Without these, you risk rejection by local authorities.

- Physical Dimensions: Verify the cutout dimensions, overall depth, and lid thickness against your architectural drawings and flooring specifications. This ensures a flawless, flush fit.

Partnering with a knowledgeable local supplier like GoSwitchgear provides access to fully compliant, regionally appropriate floor box sockets and the expert guidance needed to make the right procurement decision every time.

Common Questions About Floor Box Sockets

When specifying floor box sockets for projects in the GCC, several questions frequently arise. Whether you are an engineer, an on-site electrician, or a facility manager planning a fit-out, clarifying these details is crucial. Here are straightforward answers to the queries we most often hear from professionals in Dubai, Abu Dhabi, and across the region.

What's the Minimum IP Rating for a Commercial Office in the UAE?

For most standard indoor commercial applications in the UAE, such as offices or retail spaces with regular floor cleaning, a minimum rating of IP44 should be specified. This provides adequate protection against water splashes and solid objects larger than 1mm.

However, consider the specific location. For areas with higher dust exposure or a greater risk of water ingress—such as large atriums or busy public lobbies—it is prudent to specify a higher rating. Selecting IP65 or IP67 is a safer investment that will result in a more durable long-term installation.

Can I Mix Power and Data in the Same Floor Box?

Yes, many modern floor box sockets are designed as modular or hybrid units specifically for this purpose, allowing the combination of power with low-voltage data or AV connections. The key consideration is proper segregation.

It is absolutely critical that the box features a physical barrier separating the power and data compartments to prevent electromagnetic interference (EMI), which can degrade network performance. Always verify that the floor box complies with local electrical codes regarding the separation of different voltage systems within a single enclosure—this is a non-negotiable point for project approvals in the UAE.

How Do I Choose Between a Pop-Up and a Recessed Floor Box?

The choice depends on aesthetic requirements, frequency of use, and safety considerations. Each style offers distinct advantages for different environments.

- Pop-up boxes excel in aesthetics. When closed, they sit almost perfectly flush with the floor, which is ideal for high-end boardrooms and minimalist interiors where a seamless look is desired. The trade-off is that they can present a more pronounced trip hazard when open and in use.

- Recessed boxes with a flip-top lid are the functional workhorses. They allow cables to exit while the cover is mostly closed, maintaining a much lower profile. This design offers better protection for connected plugs and is the preferred choice for high-traffic areas where safety and durability are the primary concerns.

For a comprehensive selection of floor boxes designed for the demanding GCC climate, explore the extensive catalogue at GoSwitchgear. Find the ideal solution for your next project at https://goswitchgear.ae.

Leave a Reply