A Complete Guide to PVC Conduit Pipes for Projects in the UAE & GCC

For any major construction project in the UAE, from Dubai's skyscrapers to industrial hubs in Abu Dhabi, PVC conduit pipes are the critical, unseen network protecting electrical wiring. For engineers, electricians, and procurement teams, selecting the right conduit is fundamental to ensuring safety, organisation, and long-term system reliability in the demanding GCC climate.

The Foundation of Electrical Safety in the UAE & KSA

At its core, every electrical system needs a solid framework to shield wiring from mechanical stress, moisture, and chemical exposure. Here in the UAE and across the GCC, PVC conduit pipes are the go-to solution for this vital task. Their role is not just about tidiness; it's a fundamental part of electrical safety and system longevity, built to withstand local environmental challenges.

This guide details how this vital component stands up to the unique challenges of the GCC climate, from extreme heat and humidity to dust. Proper selection and installation are non-negotiable for project efficiency and compliance with local regulations. To fully grasp why PVC conduits are so important, it helps to understand the wider electrical industry insights and best practices that shape our work.

Why PVC Conduits are Critical in the GCC

The rapid pace of construction in the region demands high-quality electrical components. For panel builders and switchgear assemblers, sourcing reliable materials is a necessity. The GCC PVC pipes market, including conduits, was valued at USD 1.78 billion in 2024 and is projected to reach USD 2.63 billion by 2033. This growth is driven by the UAE's investment in sectors that depend on durable, corrosion-resistant PVC conduits.

Key advantages for the GCC environment include:

- Corrosion Resistance: Unlike metal, PVC is immune to rust and degradation from the humid, saline air common along the UAE coastline. This is a crucial performance factor for any electrical components UAE projects require.

- Electrical Insulation: As a natural insulator, PVC provides an extra layer of safety against short circuits and electrical shocks, a core principle of worksite safety.

- Cost-Effectiveness: PVC is typically more affordable than metal alternatives. Its lightweight nature also reduces transport and labour costs, a significant benefit for large-scale projects in Dubai and Abu Dhabi.

By mastering the selection and application of PVC conduit pipes, engineers and procurement teams can significantly enhance project safety, reduce long-term maintenance costs, and ensure compliance with local regulations.

Ensuring your team is proficient in these areas is crucial. For those looking to enhance their team's expertise, GoSwitchgear offers valuable resources, including our comprehensive electrical safety training. This guide serves as a practical resource for selecting and installing the right conduit system for your next project.

Choosing The Right PVC Conduit For Your Project

Selecting the correct type of PVC conduit pipes directly impacts the safety, longevity, and efficiency of your electrical system. Each type is engineered for specific applications and environments. Before specifying, having a firm grasp of general conduit information is essential for protecting electrical wiring. For any project in the UAE and GCC, the smart choice involves matching the conduit’s properties to the unique demands of the job site.

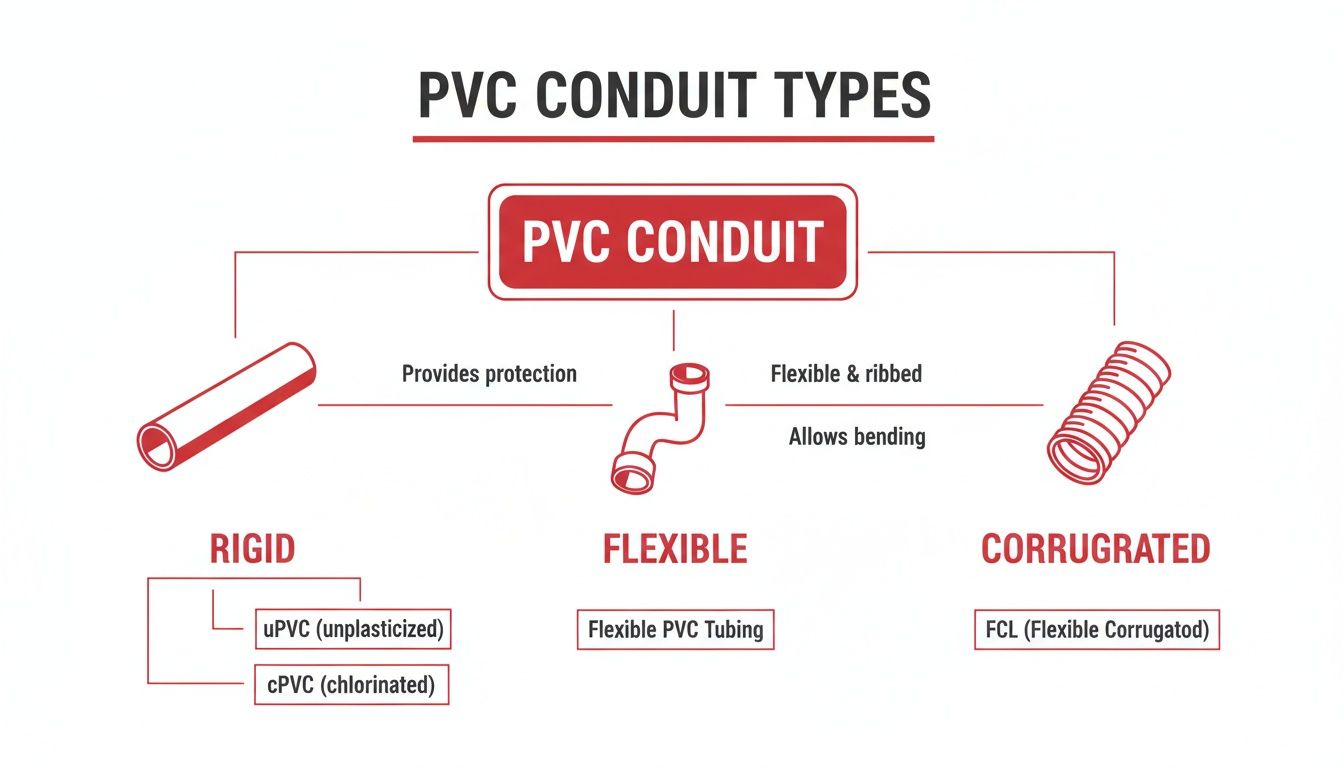

Let's break down the three main types of PVC conduit—Rigid, Flexible, and Corrugated—to help you specify the ideal product for any application.

Rigid PVC Conduit (uPVC)

For long, straight runs of electrical wiring, Rigid PVC, or uPVC (unplasticised polyvinyl chloride), is the standard. It provides a straight, tough, and secure pathway for cables, acting as the reliable backbone of a conduit system.

Key features for GCC applications:

- High Impact Resistance: Offers excellent protection against physical damage, making it ideal for exposed installations in commercial buildings, industrial plants, and utility projects across the UAE.

- Structural Integrity: Its rigidity prevents sagging over long distances, which is crucial for smooth and efficient cable pulling.

- UV Resistance: In the sun-intensive environment of the UAE, UV-stabilised versions are available, making them perfect for outdoor applications like solar farms or wiring runs on external walls.

Consider a new commercial tower in Dubai. For long vertical risers and straight pathways encased in concrete or mounted on walls, Rigid PVC is the undisputed standard, guaranteeing circuit protection for the long term.

Flexible PVC Conduit

Flexible PVC conduit provides adaptability where rigid pipes cannot. It is designed for final connections to equipment that may vibrate or for navigating tight, awkward spaces with multiple bends.

In any electrical system, flexibility is a problem-solver. Flexible PVC conduits are essential for the final connection to machinery, motors, and HVAC units, as they absorb vibrations that would otherwise stress and break rigid connections over time.

Imagine connecting a large motor in a manufacturing plant in Abu Dhabi. The constant vibration would quickly fatigue a rigid connection. A short length of Flexible PVC conduit acts as a shock absorber, isolating the main conduit run from this movement and ensuring system longevity. You can explore how a flexible electrical conduit is used in demanding industrial settings.

Corrugated PVC Conduit

With its unique ribbed design, Corrugated PVC conduit excels at bending and withstanding pressure. It is a preferred choice for underground applications or for routing through walls and ceilings where the path is irregular.

Why it’s so useful:

- Extreme Flexibility: It can be easily bent by hand to navigate around obstacles without special heating or bending tools.

- Good Compression Strength: The corrugated structure helps the conduit resist the immense pressure of being buried in the ground or encased in concrete.

This makes it an excellent option for pre-casting into concrete slabs or for residential wiring where speed and ease of installation are priorities.

Comparison of PVC Conduit Pipe Types for GCC Applications

This table provides a quick comparison to help you match the right conduit to your project's needs, with a focus on challenges specific to the GCC region.

| Conduit Type | Primary Application | Key Mechanical Property | Best Suited For (GCC Context) |

|---|---|---|---|

| Rigid PVC (uPVC) | Exposed straight runs, surface mounting, concrete encasement | High impact strength, rigidity | Commercial towers, solar farms, industrial plant backbones |

| Flexible PVC | Final connections to motors, transformers, and equipment | High flexibility, vibration absorption | HVAC units, vibrating machinery, tight equipment connections |

| Corrugated PVC | Concealed wiring, underground runs, pre-cast concrete | Extreme flexibility, good crush resistance | Residential buildings, underground utility connections |

Ultimately, understanding these differences enables engineers and procurement teams to confidently source the right PVC conduit pipes from suppliers, ensuring every part of the electrical system is robust, compliant, and suited for its environment.

How PVC Conduits Conquer the GCC Climate

The GCC environment—with its intense UV radiation, high humidity, dust, and salty coastal air—is harsh on building materials. This is where PVC conduit pipes become a strategic choice for any electrical installation in the region, offering a reliable energy management solution Dubai projects can count on.

When specifying materials for a project in Dubai or Abu Dhabi, long-term performance in this punishing climate is paramount. Unlike metal counterparts, PVC conduits are naturally immune to the primary environmental threats in the GCC.

The Battle Against Corrosion and Humidity

In coastal areas like Dubai and Abu Dhabi, airborne salt relentlessly attacks metals, causing rust that compromises structural integrity and electrical safety. Even galvanised steel conduits eventually fail, leading to costly replacements and safety hazards.

As a polymer, PVC is inert and does not react to salt or moisture. It provides a permanent shield for wiring, ensuring the conduit system remains intact for decades. This makes it the superior choice for outdoor or humid indoor applications, from beachfront properties to industrial plants. This non-corrosive feature is a major advantage when compared to options like our GI electrical conduits.

Superior Electrical Insulation Properties

Beyond weather resistance, PVC offers a fundamental safety benefit: it is a natural electrical insulator. Metal conduits are conductive, meaning a damaged wire can energise the entire conduit run, creating a severe electric shock hazard.

A PVC conduit system inherently isolates wiring, adding a critical layer of protection. This non-conductive property contains short circuits and faults, preventing their spread and enhancing the safety of personnel and equipment.

This is vital in complex systems like switchgear assemblies and control panels, where electrical integrity is non-negotiable.

Thriving Under the Sun: UV Resistance

The intense GCC sun exposes outdoor installations to high levels of ultraviolet (UV) radiation, which can make many plastics brittle over time. However, PVC conduit pipes intended for outdoor use are specifically formulated with UV stabilisers.

These additives act as a sunscreen for the material, protecting it from solar degradation. This ensures the conduit maintains its mechanical strength and does not become brittle, even after years of direct sun exposure. That's why UV-stabilised PVC is the standard for:

- Rooftop solar farm installations across the UAE.

- External wiring runs on commercial and residential buildings.

- Power connections to outdoor machinery, AC units, and lighting systems.

This diagram breaks down the main types of PVC conduit and their ideal applications, helping you select the right product for your project's environment.

As shown, rigid, flexible, and corrugated conduits each serve a distinct purpose, from providing robust support for straight runs to navigating complex bends and tight spaces.

The Cost-Benefit Analysis for Procurement Teams

For procurement managers and project engineers, the benefits of PVC directly impact the bottom line. Its lightweight nature compared to heavy metal conduits offers a significant logistical advantage.

This translates into tangible savings: lighter materials mean lower shipping costs and faster, easier on-site handling, reducing labour hours. This shift from heavy metals is a key factor in the UAE's pipes and fittings market, helping to reduce transportation costs by 20-25% in a region where logistics are critical. This is especially important as the MEA electrical conduit market grows at a world-leading 8.4%, driven by mega-projects and utility upgrades.

When you combine the lower initial purchase price, reduced transport and labour costs, and the elimination of future corrosion-related maintenance, the total cost of ownership for a PVC conduit system is significantly lower than that of its metal counterparts. It is a financially smarter and technically superior choice for the demanding conditions of the UAE and the wider GCC.

Mastering PVC Conduit Installation Techniques

The highest quality PVC conduit pipes are only effective if installed correctly. A flawless installation transforms individual components into a robust, reliable, and safe electrical system.

For electricians and panel builders in the UAE, mastering these techniques is non-negotiable. Adhering to best practices from the start prevents costly rework and ensures every project meets the highest standards for durability and compliance with local regulations, such as those from DEWA or ADDC.

Achieving Watertight Joints with Solvent Cement

In the humid climate of the GCC, a poorly sealed joint is a significant failure risk, inviting moisture that can lead to catastrophic electrical faults. The gold standard for creating a permanent, watertight bond is solvent cement welding. This is a chemical process that fuses the PVC parts into a seamless connection.

For a perfect seal, follow these steps meticulously:

- Cut Squarely: Always use a proper PVC cutter or a fine-toothed saw to achieve a clean, square cut. An angled cut will prevent the pipe from seating fully in the fitting, creating a weak point.

- Deburr Thoroughly: Use a deburring tool or knife to remove all burrs from the inside and outside edges of the cut pipe. Burrs can damage cable insulation during pulling and prevent a snug fit.

- Clean and Prime: Apply a designated PVC primer to the outside of the pipe and the inside of the fitting. The primer softens the PVC surface, preparing it for the solvent cement. This essential step is often skipped but is critical for a strong, reliable weld.

- Apply Cement Evenly: Working quickly, apply a thin, even layer of solvent cement to the outside of the pipe and a slightly thicker layer to the inside of the fitting.

- Insert and Twist: Immediately push the pipe into the fitting with a quick quarter-turn twist. This action distributes the cement evenly and helps the surfaces fuse properly. Hold it firmly for at least 30 seconds to prevent the pipe from pushing back out.

A common mistake is applying excessive cement. This does not strengthen the joint; it creates internal ridges that can obstruct or snag wires. A thin, even coat is all that is required for a chemical weld as strong as the pipe itself.

The Art of Bending PVC Conduit

Creating smooth, accurate bends without kinking or weakening the pipe is a core skill for professional electricians. While pre-made elbows are available, on-site custom bends are often necessary to navigate unique obstacles cleanly.

The key is controlled, even heat application.

A heat gun is the ideal tool. Heat the conduit evenly, rotating the pipe constantly over a section larger than the intended bend, until it becomes pliable but not scorched. Then, carefully shape it using a bending form or guide to achieve the desired angle without flattening or kinking it. A perfect bend ensures a smooth pathway for pulling wires.

Avoiding Common Installation Pitfalls

Even experienced installers can make mistakes that lead to significant problems. Awareness of these common pitfalls is the first step to avoiding them.

Here are common issues to watch for when working with PVC conduit pipes in the UAE:

- Improper Support Spacing: In the high ambient heat of the GCC, PVC conduit can sag if not supported correctly. Always follow local regulations (e.g., DEWA guidelines) and manufacturer recommendations for support spacing to maintain structural integrity.

- Over-tightening Fittings: Threaded adapters and connectors can easily crack if over-tightened. Best practice is to hand-tighten first, followed by a final quarter-turn with a wrench.

- Ignoring Expansion Gaps: PVC expands and contracts with temperature changes. For long, straight runs exposed to direct sun, installing expansion joints is mandatory. Neglecting this can cause the conduit to buckle and break over time.

Understanding Essential Conduit Accessories

An installation using pvc conduit pipes is only as strong as its weakest link. While pipes form the primary pathway for wiring, the ecosystem of accessories completes the system, ensuring its integrity, safety, and long-term reliability.

A single poorly chosen fitting can compromise an otherwise perfect installation.

This section breaks down the essential accessories for panel builders and system integrators in the UAE. Understanding each component's function is critical for creating an accurate bill of materials, avoiding project delays, and ensuring the final installation is compliant and secure.

Core Components for System Continuity

These are the fundamental building blocks of any PVC conduit network, creating continuous, protected pathways for electrical wiring.

Couplers: The simplest yet most critical fitting, used to join two straight lengths of conduit. Using the correct solvent cement is key to creating a watertight seal, which is non-negotiable in the humid conditions across Dubai and the wider GCC.

Elbows and Bends: Available in standard angles like 90° and 45°, these fittings allow for clean navigation around corners and obstacles without on-site bending. They provide a smooth, consistent radius, which is crucial for preventing cable damage during pulling.

Junction Boxes: These are the control centres of a conduit system, providing a safe enclosure for wire connections and splices or serving as a hub for changing the direction of multiple conduit runs. They are also vital access points for future maintenance and inspection.

In the dusty and occasionally wet environments across the GCC, selecting boxes with the appropriate IP (Ingress Protection) rating is mandatory for compliance and performance.

Securing and Terminating the System

Properly securing conduit runs and terminating them correctly is fundamental to safety and compliance. These accessories ensure the system remains stable and interfaces correctly with enclosures and equipment.

The integrity of a conduit system often hinges on its termination points. A correctly installed conduit gland maintains the IP rating of an entire panel or enclosure, preventing dust and moisture ingress that could lead to equipment failure.

Key components for termination and support include:

Conduit Glands and Connectors: These fittings are used to terminate a conduit run into a junction box, control panel, or switchgear enclosure. They provide a secure mechanical connection and often include seals to create a dust-tight and water-resistant entry point.

Clamps and Spacers: These support structures anchor the conduit to walls, ceilings, or other surfaces. Using the correct type and spacing is vital to prevent sagging, especially in the high ambient temperatures of the UAE, which can cause PVC to soften over long, unsupported spans.

Bushings: A small but vital component. A bushing provides a smooth, rounded surface at the end of a conduit where it enters a box, protecting cable insulation from being scraped or damaged by sharp edges during pulling.

By meticulously planning for each of these accessories, engineers and procurement teams can ensure every part of the pvc conduit pipes system is accounted for, preventing last-minute sourcing issues and guaranteeing a robust, professional-grade installation.

Your PVC Conduit Procurement Checklist

Sourcing the right PVC conduit pipes and accessories is the final, crucial step that transforms a solid plan into a successful installation. For engineers and procurement teams in the UAE, a methodical approach is essential for avoiding costly mistakes, project delays, and compliance issues.

This checklist provides a practical framework based on everything we've covered. Use it to navigate the procurement process with confidence, ensuring every component sourced meets the demanding standards of the GCC region.

Verify Compliance and Certifications

Before raising a purchase order, you must verify that the products meet both international and local standards. This is non-negotiable for project approval and long-term safety.

- Look for IEC Standards: Ensure the conduit and fittings conform to relevant International Electrotechnical Commission (IEC) standards, primarily IEC 61386, which specifies requirements for conduit systems. This is your baseline for quality.

- Confirm Local Approvals: Verify compliance with regulations from local authorities, such as DEWA in Dubai or ADDC in Abu Dhabi. Reputable suppliers should provide certificates of conformity upon request.

- Request Manufacturer Datasheets: Always ask for technical datasheets. These documents contain vital performance data, such as temperature ratings, IP ratings, and material specifications, proving the product is fit for purpose.

Confirm Technical and Dimensional Specifications

A minor mismatch in specifications can cause major installation headaches. Double-checking these details before procurement can save significant time and money on-site.

Meticulous verification prevents the logistical nightmare of receiving incorrect materials. A quick check of dimensions and ratings upfront eliminates the risk of project delays and budget overruns caused by returns and reorders.

Key details to confirm:

- Outer Diameter (OD) and Wall Thickness: Ensure these dimensions match your project requirements precisely, especially when connecting to existing systems or specific equipment.

- IP (Ingress Protection) Rating: Specify the required IP rating for all components, particularly for junction boxes and glands, to guarantee protection against dust and moisture in the UAE's challenging environments.

- UV Resistance: For any outdoor installation (e.g., solar projects, external wall runs), you must explicitly confirm you are sourcing UV-stabilised conduit designed for prolonged sun exposure.

Vet Your Supplier and Logistics

Your choice of supplier is as important as the product itself. A reliable partner ensures you receive certified materials on time and within budget, avoiding supply chain disruptions.

When evaluating suppliers, such as those on the GoSwitchgear platform, consider these points:

- Stock Availability: Can the supplier fulfill your entire bill of materials from their current stock? This is vital for avoiding piecemeal deliveries that disrupt your project timeline.

- Traceability and Authenticity: Insist on genuine products with clear manufacturer markings and batch numbers for quality assurance and traceability.

- Local Presence and Support: A supplier with a strong local presence in Dubai or Abu Dhabi can offer faster delivery and more responsive technical support, which is invaluable for fast-moving projects.

By methodically working through this checklist, you can streamline your procurement process, minimise risks, and build the foundation for a safe, compliant, and robust electrical installation.

Common Questions About PVC Conduits

Even with a strong understanding of PVC conduit pipes, practical questions often arise during projects in the UAE and GCC. Here are straight-to-the-point answers to common queries from engineers, electricians, and procurement specialists.

What's the Real Max Temperature for PVC Conduit in the UAE Heat?

Standard rigid PVC conduit is typically rated for a continuous operating temperature of around 75°C (167°F). This is sufficient for most indoor or shaded outdoor applications in the UAE.

However, direct and prolonged sun exposure on a rooftop can push surface temperatures higher. For such applications, it is crucial to use high-temperature PVC variants or consider alternative materials. Always consult the manufacturer’s technical datasheet for the exact temperature rating and ensure the conduit is not in direct contact with equipment that radiates significant heat.

Can We Bury PVC Conduits Underground for Electrical Work in the GCC?

Yes, absolutely. PVC conduits are an excellent and widely specified choice for direct burial and underground applications across the region. Their primary advantage is their immunity to moisture, soil chemicals, and corrosion, giving them a significant performance edge over metal conduits in these harsh conditions.

For direct burial, heavy-wall (Schedule 80) PVC is often used for additional mechanical strength to resist crushing from soil weight or overhead traffic. The key to a successful installation is using watertight fittings and proper solvent cementing to create a perfect seal, fully protecting the cables inside from water ingress.

How Does PVC Conduit Stack Up Against Steel for Outdoor Solar Projects?

For outdoor solar projects in the demanding UAE climate, PVC conduit offers several key advantages over traditional steel.

- Corrosion Immunity: PVC is completely immune to rust and the corrosive effects of high humidity and coastal salt spray, a common failure point for steel installations.

- Enhanced Safety: As a non-conductive material, PVC adds a critical layer of safety by preventing the entire conduit run from becoming live during a fault.

- Faster Installation: Its lightweight nature significantly reduces installation time, labour costs, and logistical challenges on large-scale solar farms.

The critical requirement is to specify UV-stabilised PVC conduit designed for outdoor exposure. Without this protection, intense sunlight will eventually degrade the material, making it brittle. While steel offers superior impact resistance, the long-term durability, safety, and cost-effectiveness of UV-rated PVC conduit pipes make it the preferred choice for most solar installations in the GCC.

For a comprehensive selection of certified PVC conduit pipes and accessories suited for the demanding requirements of the GCC market, explore the digital catalogues on GoSwitchgear.

Find the right components for your next project at https://goswitchgear.ae.

Leave a Reply