Selecting the Right Cable for a Fire Alarm System in the UAE

For any fire alarm system, the cable is the critical lifeline. It connects detectors, panels, and alarms, ensuring seamless communication during an emergency. In the demanding environments of the UAE and GCC, using standard electrical wiring is a significant failure point. For genuine safety and compliance with local regulations, specialized, certified fire-rated cables are mandatory.

The Critical Connection in Fire Safety Systems

The most advanced detectors are rendered useless if the cables connecting them fail in the first moments of a fire. This is why, in the UAE, standard electrical wiring is strictly prohibited for life-safety systems. You must use cables engineered for this specific purpose.

We will explore the two primary types of fire alarm cabling: Fire-Resistant (FR) cables, designed to maintain circuit integrity during a fire, and Low Smoke Zero Halogen (LSZH) cables, engineered to limit the spread of flames and toxic smoke.

Why Specialised Cables Are Mandatory in the UAE

Understanding the distinction between these cable types is non-negotiable for engineers, installers, and project managers aiming to meet the strict UAE Civil Defence codes. The objective is to ensure the system performs flawlessly when it matters most. Of course, these cables also require correct support structures during installation, meaning the use of appropriate cable tray accessories is essential to protect the system's integrity.

The market is responding to this increased focus on safety. The flame-retardant cable market in the Middle East & Africa was valued at approximately USD 42.85 million in 2024 and is projected for significant growth. This expansion is driven by regional governments tightening fire safety codes, mandating flame-retardant and low-smoke cables to minimise toxic smoke during emergencies.

Ultimately, selecting the correct cable for a fire alarm system is more than a line item on a specification sheet—it's about installing a lifeline for building occupants.

Decoding Fire-Rated Cable Technology

When specifying a cable for fire alarm system applications, it's crucial to look beyond technical jargon. These are not just wires; they are specialized components engineered for life-saving functions during a fire. Swapping one type for another is not an option.

Fire-Resistant (FR) cables act as the system's lifeline. They are engineered to withstand extreme heat and continue functioning. Their primary purpose is to maintain circuit integrity, ensuring power and data continue to flow to critical systems like alarms and emergency voice communications long enough for a safe evacuation.

In contrast, Low Smoke Zero Halogen (LSZH) cables are the clean air guardians. When ignited, a standard PVC cable emits thick, toxic black smoke and corrosive halogen gases. LSZH cables are designed to prevent this, which is crucial for maintaining visibility in escape routes and preventing smoke inhalation injuries.

Fire-Resistant (FR) Cable Construction

An FR cable’s resilience comes from its multi-layered construction, where each component is designed to shield the circuit from fire.

- Conductors: The core is made of high-purity copper, providing a reliable pathway for electrical signals and power.

- Insulation Layer: This is where the core technology lies. A layer of mica glass tape is wrapped directly around the copper conductors. Mica, a mineral with exceptional thermal resistance, acts as a fire barrier that insulates the core even after the outer layers have been destroyed by fire.

- Sheath: The final outer jacket provides physical protection and is typically made from a flame-retardant, low-smoke compound, adding another layer of defence.

Low Smoke Zero Halogen (LSZH) Cable Construction

With LSZH cables, the design focus shifts to mitigating the secondary dangers of a fire—smoke and toxic fumes.

- Conductors: Like FR cables, they utilize copper conductors for dependable signal transmission.

- Insulation: The insulation is a thermoplastic or thermoset compound that is completely free of halogen elements like chlorine and fluorine.

- Outer Sheath: This is the key component. The LSZH sheath is formulated to produce very little smoke when it burns and, critically, releases no toxic halogen gases. This makes them essential for enclosed public spaces like malls, metro stations, and hospitals across Dubai and the wider UAE.

Demand for these high-performance, compliant cables is growing rapidly. The global fire alarm cables market was valued at USD 1.2 billion in 2024 and is projected to reach USD 2.5 billion by 2033, with the Middle East being a major driver of this growth. The surge is fuelled by new construction projects, stricter safety regulations, and the adoption of smart fire detection systems. You can discover more insights about this growing market and understand the contributing factors.

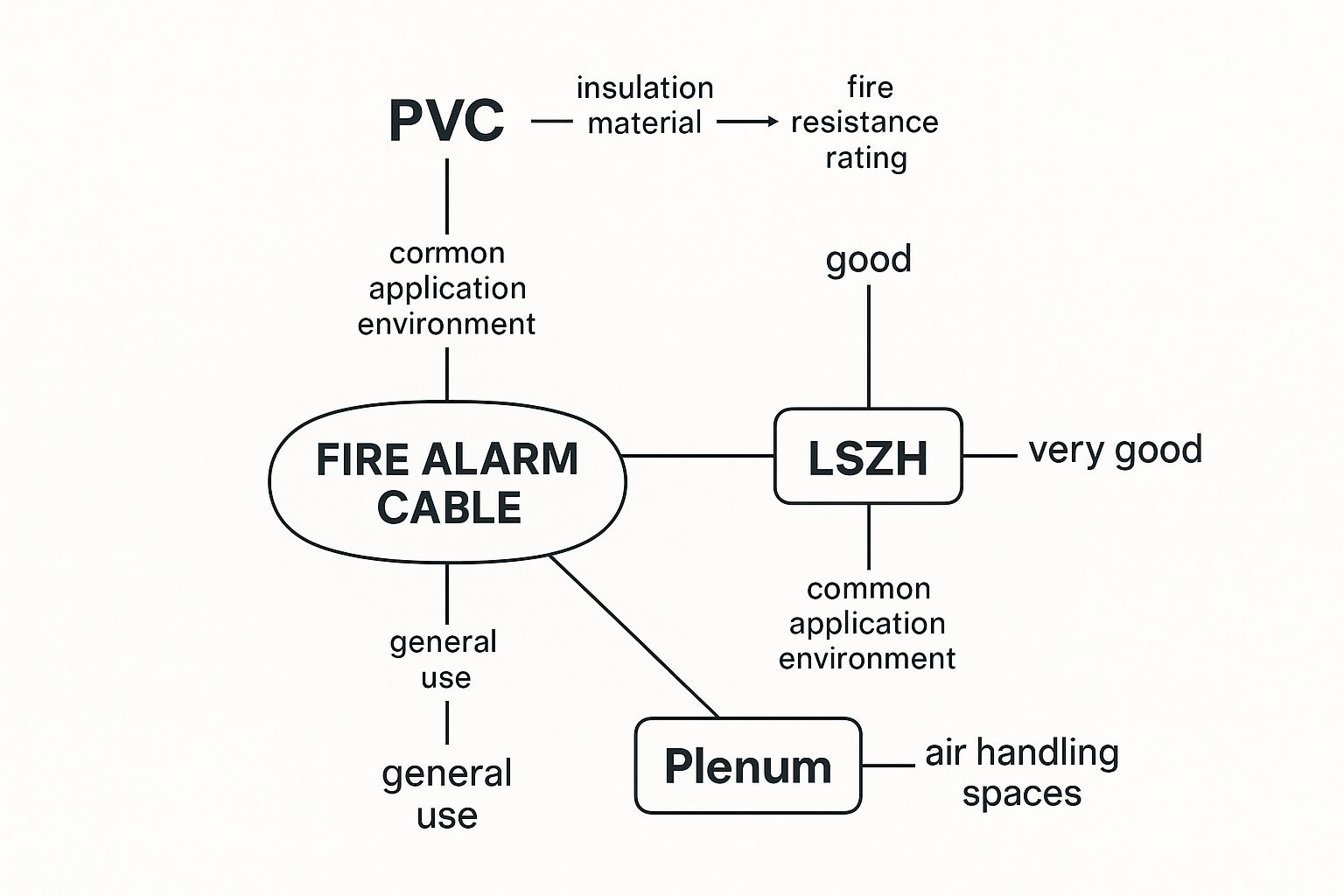

This infographic helps break down the core attributes and typical applications for different fire alarm cable types.

The decision between PVC, LSZH, and Plenum cables depends on the installation environment and its specific fire safety requirements.

To clarify the two main safety-focused types, here’s a quick comparison.

Comparing Fire-Resistant (FR) and Flame-Retardant (LSZH) Cables

This table offers a side-by-side comparison of Fire-Resistant and LSZH cables, detailing their function, application, and relevant standards.

| Characteristic | Fire-Resistant (FR) Cable | Flame-Retardant (LSZH) Cable |

|---|---|---|

| Primary Function | Maintains circuit integrity and continues to operate during a fire for a specified time. | Reduces the spread of fire and limits the emission of smoke and toxic halogen gases. |

| Key Material | Mica glass tape insulation acts as a thermal barrier around the conductor. | Halogen-free compounds in the insulation and outer sheath that don't release toxic fumes. |

| Performance in Fire | Continues to transmit power/data even when directly exposed to flames. | Self-extinguishes once the flame source is removed; produces minimal smoke. |

| Typical Application | Essential life-safety circuits: emergency lighting, voice alarm systems, fire pumps. | Public and enclosed spaces: airports, tunnels, hospitals, high-rise buildings, data centers. |

| Governing Standards | IEC 60331, BS 7629-1 | IEC 60332, IEC 60754, IEC 61034 |

While both are crucial for fire safety, they address different challenges. FR cables keep systems operational, while LSZH cables make the environment safer for evacuation. The construction of a cable for a fire alarm system directly impacts its performance. For engineers and installers in the GCC, understanding these material differences is essential for designing a compliant and life-saving system.

Navigating UAE and International Fire Cable Standards

In the UAE and the wider GCC, compliance with fire safety standards is mandatory and strictly enforced. Selecting a cable for fire alarm system projects means choosing a product that meets a high bar of international and regional regulations. Non-compliance can lead to project delays, failed inspections, and severe safety risks.

For engineers and procurement teams, mastering this regulatory landscape is critical. It requires understanding what the standards test for and why it matters during a fire. This knowledge is your best tool for ensuring the chosen cables perform under pressure and meet the stringent requirements of bodies like the UAE Civil Defence.

Key International Standards for Fire Cables

Global benchmarks form the basis of fire cable safety, creating a common language for performance that authorities across the GCC recognize.

-

IEC 60331 (Tests for electric cables under fire conditions – Circuit integrity): This is the ultimate stress test for fire-resistant cables, verifying if a cable can maintain power flow while exposed to fire and mechanical shock, simulating real-world conditions like falling debris.

-

BS 7629-1 (Electric cables – Specification for 300/500 V fire-resistant screened cables): This British Standard is widely referenced in the UAE. It outlines requirements for screened, fire-resistant cables used in fire detection, alarm, voice alarm, and emergency lighting systems.

-

IEC 60332 (Tests on electric and optical fibre cables under fire conditions): This standard assesses how well a cable resists spreading flames along its length, a critical factor in containing a fire.

-

IEC 60754 (Test on gases evolved during combustion of materials from cables): Essential for LSZH cables, this standard ensures the cable does not release acidic, corrosive gases that can damage sensitive electronics and pose a health hazard.

-

IEC 61034 (Measurement of smoke density of cables burning under defined conditions): This test measures the amount of smoke a burning cable produces. Low smoke density is vital for keeping escape routes visible during an evacuation.

The Role of Local Regulations and Third-Party Certifications

While international standards provide the technical foundation, local authorities like the UAE Civil Defence and Saudi Civil Defence have the final jurisdiction. Their fire and life safety codes often specify which standards are mandatory for different building types.

For any project in the GCC, always consult the latest edition of the local Civil Defence code. These documents are the ultimate authority and will dictate the minimum required performance standards for your fire alarm system cabling, superseding even international norms if there is a conflict.

In addition to local enforcement, third-party certifications offer proof of quality. Approvals from globally recognized labs provide independent verification that a product has been rigorously tested.

- LPCB (Loss Prevention Certification Board): An LPCB approval is one of the most respected marks in the fire safety industry, indicating that a cable meets top performance standards.

- UL (Underwriters Laboratories): A UL-listed fire alarm cable is a universally recognized sign of proven safety and reliability.

The regional construction boom has significantly increased demand for certified, high-performance cables. In 2023, approximately 2.5 million kilometers of fire-resistant cables were installed in the Middle East & Africa, a 7% increase from the previous year, largely driven by the strict enforcement of these standards in the GCC.

For a broader understanding of cabling infrastructure, reviewing resources on structured cabling standards in Dubai is advisable. A firm grasp of these standards ensures your fire alarm system is not just compliant but built for maximum resilience.

Making the Right Cable Choice for Your System

Selecting the correct cable for a fire alarm system is a critical strategic decision that demands a methodical approach, balancing system design, installation environment, and regulatory compliance. For engineering and project teams in the UAE, getting this right is fundamental to a project's success.

The first step is to analyze the system's architecture. The cable requirements for a simple conventional system differ significantly from those of a complex, data-intensive addressable system.

Matching Cable to Circuit Function

Not all circuits have the same function. An initiating device circuit (IDC) connecting smoke detectors has different performance needs than a notification appliance circuit (NAC) powering alarms.

- Detector Loops (IDC/SLC): These circuits form the system's nervous system, carrying low-voltage data signals. For addressable systems (Signalling Line Circuits or SLCs), shielding is non-negotiable to protect against electromagnetic interference (EMI), which can cause false alarms or communication failures.

- Sounder & Bell Circuits (NAC): These circuits carry higher power to activate alarms. The critical factor here is conductor size (measured in mm² or AWG), which must be sufficient to handle the current load over distance without significant voltage drop.

- Power Supply Lines: These cables must have adequate voltage and current ratings to reliably power the main fire alarm control panel (FACP) and any remote power units.

Key Technical Criteria for Selection

After mapping out the circuits, it is time to define the technical specifications. A detailed specification sheet ensures procurement obtains the correct components.

A proper spec sheet should define these four points:

- Voltage Rating: The cable must be rated for the system’s operating voltage, typically 300/500V for fire alarm applications.

- Conductor Size: This is determined by the circuit's current draw and length. Undersizing conductors is a common and dangerous mistake.

- Shielding: For SLCs in addressable systems, an aluminum foil shield with a drain wire is standard practice in the GCC to defend against EMI.

- Number of Cores: Most circuits use 2-core cables, but some applications may require 4-core or multi-pair configurations.

Addressing the GCC Climate Challenge

The intense heat, humidity, and dust across the UAE and GCC region place significant stress on all electrical components. A cable suitable for a milder climate can fail rapidly here.

The outer sheath is a cable's first line of defence. In the GCC, specifying a cable with a UV-resistant and high-temperature-rated sheath (often 90°C or higher) is a necessity for long-term reliability.

Compromising on environmental specifications can lead to premature sheath cracking and insulation breakdown. Always review the manufacturer's datasheet to confirm temperature ratings and material specifications, ensuring the chosen cable for a fire alarm system can withstand harsh local conditions. Proper termination is equally crucial; understanding different electrical cable lugs types ensures a secure, long-lasting connection.

By systematically analyzing the system type, circuit function, technical specs, and local environmental pressures, you can develop a precise cable specification. This approach eliminates guesswork and guarantees the selection of a cable that delivers unwavering performance.

Installation Best Practices for the GCC Climate

Even the highest quality cable for a fire alarm system is only as reliable as its installation. For technicians working in the demanding conditions of the UAE and GCC, flawless installation is non-negotiable. It is the critical step that transforms a well-designed system into a dependable, long-term asset.

Proper installation protects the cable’s internal structure, prevents signal interference, and ensures compliance with local Civil Defence regulations. Getting it right the first time saves money, avoids rework, and, most importantly, protects lives.

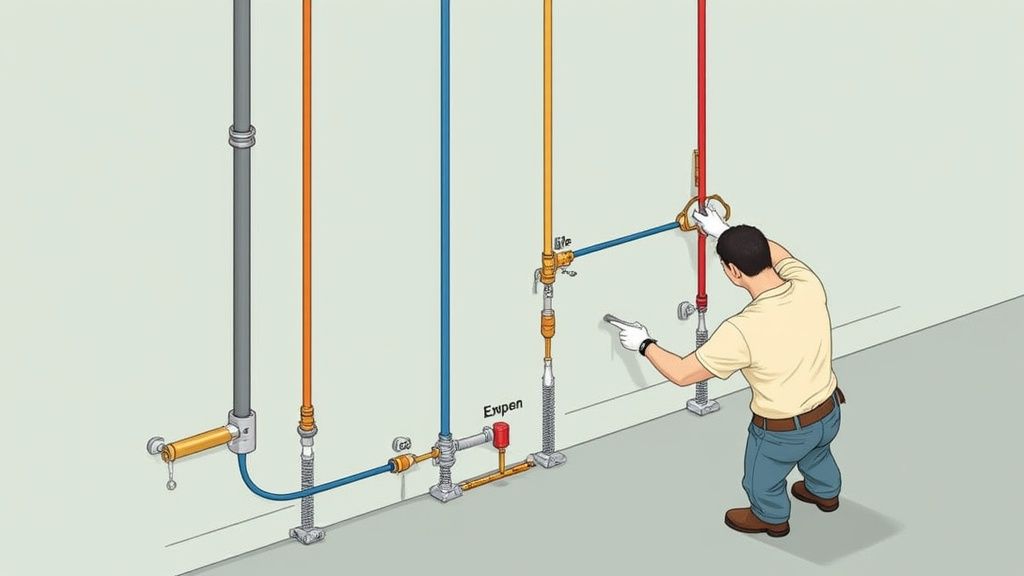

Handling and Routing Cables Correctly

The physical integrity of a fire alarm cable is paramount. Any damage during installation can create a weak point that fails during an emergency. Adherence to the manufacturer's guidelines is therefore essential.

One of the most important rules is respecting the minimum bending radius. Forcing a cable into a tight corner can stretch conductors, crack insulation, and compromise the shield. As a rule of thumb, the bending radius should be at least 10 times the cable's outer diameter. This simple practice prevents latent damage.

Additionally, proper support is vital, especially given the high ambient temperatures in the GCC. Cables must be supported at regular intervals using fire-rated clips, saddles, and fixings.

Using standard plastic clips or zip ties is a critical error. In a fire, they will melt and fail, allowing cables to sag and potentially severing the circuit. Always use metallic, fire-rated fixings certified to withstand the same extreme temperatures as the cable itself. This maintains circuit integrity when it matters most.

Avoiding Common and Costly Installation Mistakes

Several common installation errors can undermine the reliability of a fire alarm system. Avoiding these is the mark of a professional and is closely scrutinized by Civil Defence inspectors in Dubai and Abu Dhabi.

The most common mistake is running fire alarm cables adjacent to high-voltage power wiring. Fire alarm circuits, especially sensitive SLC loops, are highly susceptible to electromagnetic interference (EMI).

Placing them in the same conduit or tray as power cables can lead to:

- False alarms that cause disruption and complacency.

- Communication errors between detectors and the control panel.

- Total system failure in cases of severe interference.

UAE regulations mandate physical segregation. Fire alarm cables require their own dedicated conduits or trunking to protect signal integrity. Understanding the rules for different cable types is key for compliance. For example, knowing the specifications for various armoured cable sizes helps in planning separate pathways for power and life-safety systems.

Here’s a quick guide to best practices.

Fire Alarm Cable Installation Do's and Don'ts

| Do | Don't |

|---|---|

| Use dedicated conduits for all fire alarm wiring to prevent EMI. | Run fire alarm cables in the same tray or conduit as power, data, or lighting cables. |

| Respect the minimum bending radius specified by the manufacturer. | Force cables around sharp corners or pull them with excessive force. |

| Use certified fire-rated clips and metallic fixings for all supports. | Use plastic cable ties or non-metallic clips that will melt in a fire. |

| Seal all conduit penetrations through fire-rated walls with approved firestop materials. | Leave gaps around cables passing through fire barriers, which would compromise compartmentation. |

| Test every circuit for continuity and ground faults after installation. | Assume the cable is fine without thorough testing and commissioning. |

Following these rules is fundamental to a professional and compliant installation.

Adhering to Maintenance and Inspection Schedules

Installation is the beginning of the system's service life. Across the UAE, Civil Defence enforces strict schedules for regular inspection and maintenance to ensure fire alarm systems remain operational.

Technicians must maintain detailed logs of all tests and inspections. This documentation is crucial for compliance and provides a valuable performance history. A system installed correctly from the outset, using the right cable for fire alarm system applications and professional techniques, will pass these inspections, proving its value as a reliable life-safety asset.

Putting It All Together: Meeting Your Fire Safety Goals

Let's recap the key principles for selecting the right cable for fire alarm system projects. The integrity of your entire life-safety system depends on the quality of its cabling.

We have reviewed the crucial differences between fire-resistant and LSZH cables. One maintains system operation during a fire, while the other protects evacuation routes from toxic smoke. Both are critical depending on the application.

The Cornerstones of a Successful Installation

Adherence to both UAE and international standards is non-negotiable. Compliance with benchmarks like IEC 60331 and local Civil Defence codes not only ensures safety but also prevents costly project delays.

Installation quality is paramount. A superior cable will fail if handled incorrectly. Proper installation—avoiding kinks, using correct fixings, and segregating from power lines—is everything.

This knowledge empowers engineers, installers, and procurement managers to make informed decisions that prioritise life safety and compliance. A reliable system starts with quality components and expert installation.

If you require specific guidance for your project in Dubai, Abu Dhabi, or anywhere across the GCC, the team at GoSwitchgear is here to provide expert technical support and product recommendations to ensure your fire alarm system is built on a foundation of proven reliability.

Got Questions? We've Got Answers

When dealing with a component as critical as a cable for a fire alarm system, questions are inevitable. Here are some of the most common queries we receive from professionals across the UAE and GCC.

What's the Real Difference Between FR and LSZH Cables?

The distinction is crucial as it dictates their application.

An FR (Fire-Resistant) cable is designed to continue operating during a fire. Its purpose is to maintain circuit integrity for essential systems like alarms and emergency communications, providing valuable time for a safe evacuation.

An LSZH (Low Smoke Zero Halogen) cable, conversely, focuses on damage control and personnel safety. It is designed to limit the spread of flame and, when it burns, produces minimal smoke and no toxic halogen gases. This keeps escape routes clearer and the air safer.

In short, one cable keeps the system operational, while the other makes the environment less hazardous.

What Colour Should Fire Alarm Cables Be in the UAE?

In a complex installation, immediate identification of critical wiring is essential. Regulations mandate a specific colour for fire alarm cables to ensure this.

According to the UAE Fire and Life Safety Code of Practice, these cables must have a red outer sheath. This distinct colour immediately identifies the wiring as part of a life-safety system.

It is always best practice to consult the latest local Civil Defence regulations for your specific project, as codes are subject to updates.

Can I Run Fire Alarm Cables in the Same Conduit as Other Wires?

Absolutely not.

Regulations throughout the UAE and GCC are explicit on this point. Fire alarm system cabling cannot be run in the same conduit, trunking, or tray as other electrical wiring, such as power or lighting circuits, for two key safety reasons.

First, it prevents electromagnetic interference (EMI). High-voltage lines can induce electrical "noise" in sensitive fire alarm circuits, potentially causing false alarms, communication errors, or complete system failure.

Segregating life-safety wiring is a fundamental principle of compliant installations. It protects the integrity of the fire alarm system from faults or electrical noise originating in other building systems, ensuring it remains reliable and ready to perform when needed most.

Second, it protects the physical integrity of the fire system. A fault in an adjacent power circuit could cause it to overheat and destroy the fire alarm cabling bundled with it. A dedicated pathway is essential for a resilient and dependable system.

Need expert help choosing the right certified cable for a fire alarm system for your project in Dubai, Abu Dhabi, or anywhere else in the GCC? The technical team at GoSwitchgear is ready to assist. Check out our complete range of compliant electrical components at https://goswitchgear.ae.

Leave a Reply