Choosing the Right Clamp Meter for UAE and GCC Projects

For professionals in the UAE and wider GCC, a clamp meter is an indispensable diagnostic tool for ensuring operational safety, accuracy, and continuity. On Dubai's high-rise construction sites or within Saudi Arabia's industrial plants, standard equipment often fails to meet the region's unique environmental challenges. Selecting the right instrument for precise, non-contact current measurement is critical for project success and safety.

Why Your Clamp Meter Choice Is Critical in the GCC

Selecting the right clamp meter is a serious decision for electricians, engineers, and panel builders across the Gulf. The combination of intense heat, high humidity, and pervasive dust creates a demanding environment where only the most robust and reliable tools perform consistently.

A generic clamp meter may provide a basic reading in a controlled setting, but it often lacks the durability and precision required for demanding local applications. An inaccurate measurement can lead to incorrect diagnoses, equipment failure, and significant safety risks, particularly when working with the high-energy circuits common in the region's commercial and industrial facilities. This is where a specialized, high-quality instrument from a trusted supplier of electrical components UAE professionals rely on proves its worth as a vital energy management solution Dubai projects need.

Meeting Regional Demands

The explosive growth in the Middle East's energy and infrastructure sectors has fueled significant demand for top-tier clamp meters. The Earth Leakage Clamp Meters segment in the MEA region alone constitutes approximately 10% of the global market, a figure directly reflecting the rapid urbanization and industrial projects in countries like the UAE and KSA. These tools are vital for non-intrusive current checks in high-voltage settings. You can explore the market data on this sector's growth.

At GoSwitchgear, we understand these challenges intimately. We specialize in supplying robust electrical components and testing solutions engineered to withstand the GCC's demanding conditions. This guide provides expert insights to help you make a confident decision for your next project, whether in Dubai, Abu Dhabi, or elsewhere in the region.

How a Clamp Meter Actually Works

The primary advantage of a clamp meter is its ability to measure electrical current without cutting wires or interrupting power. By sensing the magnetic field that naturally forms around any live conductor, it provides a safe, non-intrusive reading. For professionals working on critical systems across Dubai and Abu Dhabi, this capability is a game-changer.

The core principle is electromagnetic induction. When the jaws are clamped around a single wire, the magnetic field from the current flowing through it is channeled through the meter’s iron core. This induces a smaller, proportional current within the meter's windings, which is then calculated and displayed as a precise amperage reading.

Understanding AC vs DC Current Measurement

Not all currents are the same, and your meter must be equipped for the specific application. The distinction between Alternating Current (AC) and Direct Current (DC) is fundamental for anyone working in the UAE's diverse electrical landscape, from high-rise buildings to large-scale solar farms.

- AC Clamp Meters: These are the most common type, operating on a simple current transformer principle. They are ideal for measuring the constantly changing magnetic field produced by AC, making them suitable for standard building wiring, HVAC units, and most industrial machinery.

- DC Clamp Meters: DC current produces a steady magnetic field that a standard AC meter cannot detect. To measure it, these meters employ a Hall Effect sensor. This sensor directly measures the magnetic field's strength and converts it into a voltage, which the meter then displays as current.

A DC-capable clamp meter is essential for projects involving solar panel installations, battery backup systems, or automotive electronics—all rapidly growing sectors in the GCC. An AC-only meter will simply register zero on a DC circuit.

Field Tip: When measuring DC, most meters feature a "ZERO" or "REL" button. Press this before clamping onto the conductor to nullify stray magnetic fields from nearby equipment, ensuring an accurate reading.

Why True-RMS is Non-Negotiable for Modern Systems

A feature that is now an absolute necessity is True-RMS. Modern systems, such as variable frequency drives (VFDs) and sophisticated electronic power supplies, generate distorted, "non-linear" electrical waveforms rather than clean sine waves.

A basic, non-True-RMS clamp meter uses an averaging formula that is only accurate for perfect sine waves. When applied to a distorted waveform, the reading can be off by as much as 40%. This level of inaccuracy can lead to misdiagnosing a functional motor or, more critically, failing to identify a dangerously overloaded circuit.

A True-RMS clamp meter utilizes a more advanced calculation to measure the actual "heating value" of any waveform, whether it's a clean sine wave, a square wave, or a complex signal from a VFD. It delivers the true root mean square value, providing an accurate and trustworthy measurement every time. For any serious electrician or engineer in the UAE, a True-RMS meter is a core requirement for safe and precise work. You can check our lineup of professional testing tools on the GoSwitchgear electrical components UAE page.

Decoding Technical Specs for the GCC Climate

The true test of a clamp meter is its performance on a bustling job site in Dubai or within a remote industrial facility near Riyadh. Understanding how datasheet specifications translate to performance in the harsh GCC climate is what separates an adequate tool from a sound investment. Let’s break down the specs that matter in the field.

Jaw Size Matters for Large Installations

For professionals in the UAE working on main distribution panels or heavy industrial switchgear, a large jaw opening is essential. Many installations use thick, high-current busbars or bundled parallel conductors that a small-jawed meter cannot accommodate. Attempting to use a clamp that is too small or does not close properly will yield dangerously misleading readings. Ensure the jaw size can handle the largest conductors on your projects.

Matching Current Range to Your Application

A versatile clamp meter must handle both high-power feeders and delicate control circuits.

- High Current Range (e.g., 600A/1000A): Non-negotiable for measuring loads on main circuits, large motors, and primary feeders.

- Low Current Range (e.g., 600mA or lower): Crucial for troubleshooting control systems, identifying parasitic drains in battery systems, and checking for earth leakage currents.

For procurement teams, specifying a meter with a wide range ensures your crew has a versatile tool for nearly any task, maximizing its value.

Environmental Durability with IP Ratings

In the GCC, electrical faults are compounded by intense heat, fine airborne dust, and corrosive coastal humidity. An Ingress Protection (IP) rating is a critical specification.

An IP rating, such as IP54, indicates how well the meter is sealed against solids and liquids. The first digit (5) signifies a high degree of dust protection, while the second (4) means it is protected against water splashes. For a tool used on exposed construction sites, a robust IP rating is your best guarantee of a long, reliable service life. Ignoring this spec can lead to premature equipment failure from dust ingress or humidity-induced corrosion.

The Critical Importance of CAT Safety Ratings

The most important specification is the safety rating. The CAT (Category) rating indicates if a meter can withstand a transient voltage spike—a sudden surge of energy that can cause catastrophic failure and a deadly arc flash. Understanding CAT ratings is a critical safety requirement tied to your work environment.

Understanding Clamp Meter Safety Ratings CAT III vs CAT IV

| Safety Rating | Voltage Level | Typical Application | Why It Matters in the GCC |

|---|---|---|---|

| CAT III | 1000V | Three-phase distribution systems, switchgear, panel boards, and large fixed motors in commercial or industrial buildings. | Ideal for most downstream commercial and industrial work after the main utility connection. |

| CAT IV | 600V | Measurements at the source of the low-voltage installation, like utility service drops, main panels, and electricity meters. | Absolutely essential for anyone working at or near the utility connection point. This is the highest level of protection. |

Working near a utility source in a Dubai high-rise or an Abu Dhabi industrial plant demands a meter rated for at least CAT IV 600V or CAT III 1000V. Using a lower-rated instrument in these environments is an unacceptable safety risk. At GoSwitchgear, we stock a range of electrical components UAE professionals depend on, including meters with the correct safety ratings for every job.

Mastering Field Techniques and Safety Protocols

A top-tier clamp meter is only effective when used safely and correctly, especially within the complex electrical panels found on projects across the UAE. Proper technique not only guarantees accurate readings but is also fundamental to preventing serious electrical hazards.

A pre-use check is non-negotiable. Inspect the meter's housing for cracks, ensure test leads are not frayed, and confirm the function dial operates correctly. Equally critical is wearing the right Personal Protective Equipment (PPE), including arc-rated clothing, safety glasses, and insulated gloves rated for the voltage level.

Step-by-Step Current Measurement

Consistent methodology is key to obtaining reliable data every time.

How to Measure AC or DC Current:

- Select the Right Function: Turn the dial to the correct current setting—A~ for AC or A⎓ for DC. If your meter is not auto-ranging, select the appropriate range.

- Zero the Meter (Crucial for DC): When measuring DC current, press the "ZERO" or "REL" button before clamping to cancel out background magnetic fields.

- Clamp a Single Conductor: Open the jaws and clamp them around only one wire. Clamping both live and neutral wires will result in a zero reading as their magnetic fields cancel each other out.

- Center the Conductor: For optimal accuracy, position the wire in the center of the jaws.

- Record the Reading: The display will show the real-time current.

Capturing Motor Inrush Current

When a motor starts, it draws a massive, brief surge of current known as inrush, which can be 5 to 15 times the normal running current. Standard clamp meter settings are too slow to capture this event. Models with a dedicated "Inrush" function are designed for this purpose.

To measure inrush, select the inrush function, clamp the motor’s main supply wire, and then start the motor. The meter will capture and hold the peak current from the initial surge, providing invaluable data for diagnosing nuisance breaker trips and sizing motor protection correctly.

Essential Voltage Verification

Before touching any circuit, you must verify it is de-energized, a life-or-death safety step mandated by standards like IEC 61010. Never trust that a breaker has operated correctly—always test to confirm.

Lockout/Tagout (LOTO) and Voltage Testing:

- Isolate the Circuit: De-energize the power source and apply your personal lock and tag.

- Test Your Meter: Check your meter on a known live source to confirm it is working correctly.

- Test the Target Circuit: Use your test leads to measure for voltage between phase-to-phase, phase-to-neutral, and phase-to-earth.

- Confirm Zero Voltage: The reading should be zero (or very close to it) across all tests.

- Re-test Your Meter: Test your meter again on the known live source to ensure it did not fail during the test.

This "Live-Dead-Live" testing method is the gold standard for safety and a non-negotiable procedure for every professional in the GCC.

Staying Sharp: Why Proper Calibration is Non-Negotiable

A high-quality clamp meter is a precision instrument, but its reliability depends on regular calibration. Continuous exposure to the demanding conditions of a Dubai construction site or the humid, salty air of a coastal facility can cause even the most robust instrument to drift from its factory specifications. An uncalibrated meter provides a guess, not a measurement, leading to misdiagnoses and severe safety risks.

Calibration is a meticulous process where the instrument's readings are compared against a highly precise, traceable standard, validating that every measurement is accurate and dependable. The global push for maintained accuracy is reflected in the clamp meter market analysis, which highlights the growing adoption of high-precision tools in line with stringent safety directives.

The Case for Annual Professional Calibration

While daily checks are good practice, they do not replace formal, professional calibration. We strongly recommend having your meter professionally calibrated by an accredited lab at least once a year, or more frequently if it is used heavily in harsh environments or has sustained physical impact.

Certified calibration provides:

- Traceability: A formal certificate linking your meter's performance to national and international standards.

- Confidence: Confirmation that your meter performs within the manufacturer's stated accuracy specifications.

- Compliance: Fulfillment of requirements for quality management systems like ISO 9001.

Simple Upkeep for a Long Life in the GCC

Between professional calibrations, user maintenance can significantly extend your meter’s life and reliability.

Your Quick Maintenance Checklist:

- Keep the Jaws Clean: Before each use, wipe the jaw surfaces with a clean, dry cloth to remove dust and grime, which can create air gaps and affect current readings.

- Inspect Your Test Leads: Regularly check leads for any damage to the insulation. Damaged leads are a major safety hazard and should be replaced immediately.

- Store It Smart: When not in use, store your clamp meter in its protective case. Avoid leaving it in extreme heat or humidity to protect its internal electronics.

Following these habits will protect your investment and ensure your clamp meter remains a safe and reliable tool.

Your Go-To Clamp Meter Selection Checklist

This practical checklist is designed to help professionals in the UAE cut through the noise and select the right clamp meter for their specific needs.

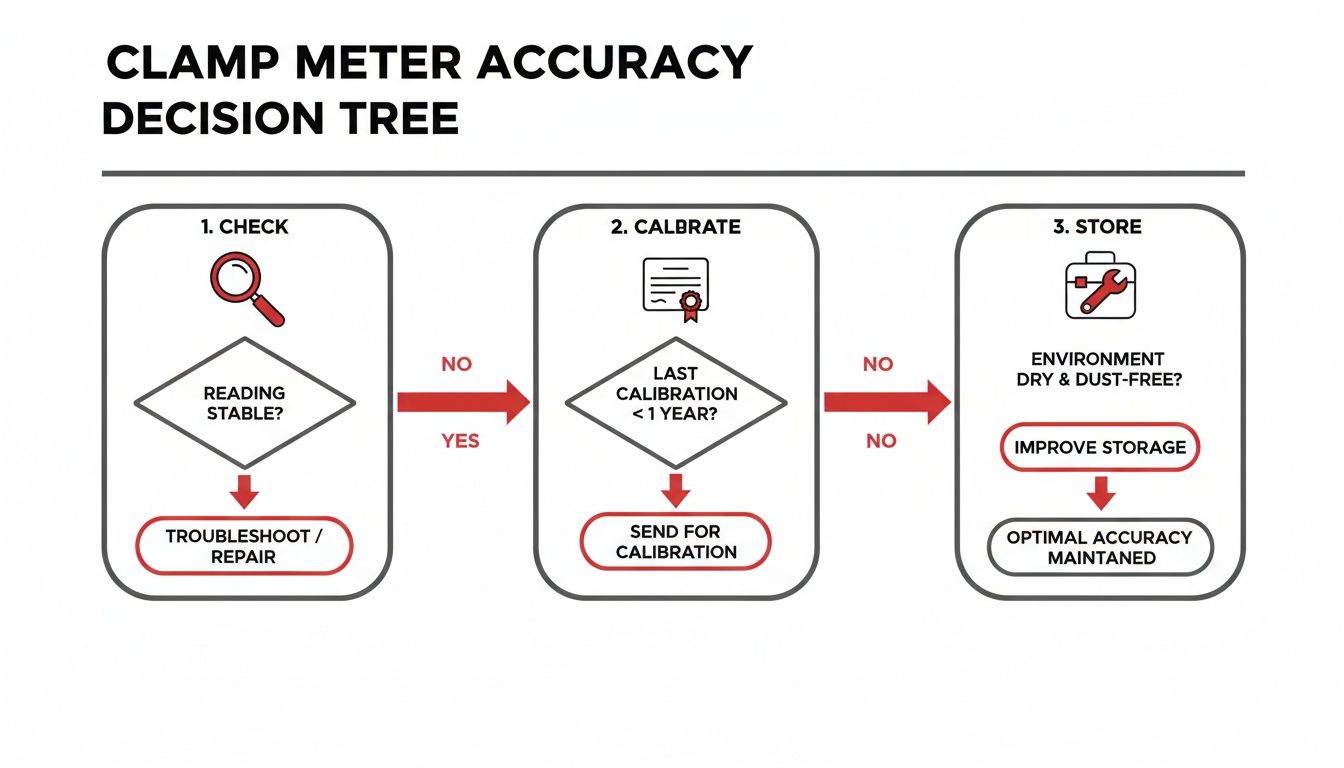

This decision tree provides a simple framework for maintaining your clamp meter's trustworthiness through regular checks, annual calibration, and proper storage.

As shown, consistent user checks, professional annual calibration, and proper storage are the pillars of long-term accuracy.

Define Your Primary Applications

Your daily tasks will determine the essential features you need.

- Switchgear and Panel Maintenance: Requires a high current range (up to 1000A), a CAT III 1000V or CAT IV 600V safety rating, True-RMS, and a large jaw for busbars.

- HVAC Systems: Needs a meter with AC/DC current capabilities, temperature functions, and a microamps (µA) range for diagnosing flame sensors.

- Solar PV Installations: A clamp meter with a high DC current rating (1000A or more) and a 1000V DC voltage rating is non-negotiable.

- General Electrical Contracting: A versatile meter with a 600A range, True-RMS, and a solid CAT III 600V rating is suitable for most residential and commercial work.

This reference table breaks down essentials by application.

Key Clamp Meter Features by Application

| Application | Typical Current Range | True-RMS Required? | Minimum Safety Rating | Key Feature |

|---|---|---|---|---|

| Switchgear/Panels | 600A – 1000A AC | Yes | CAT IV 600V / CAT III 1000V | Large jaw size for busbars |

| HVAC Systems | 400A – 600A AC/DC | Yes | CAT III 600V | Temperature, Capacitance, µA DC |

| Solar PV | 1000A – 1500A DC | Yes | CAT III 1000V DC | High DC current & voltage rating |

| General Contracting | 600A AC | Yes | CAT III 600V | Versatility, good balance of features |

This table helps you pinpoint what matters most for your work, ensuring you get the right tool for the job.

Confirm Essential Specifications

These core specs are non-negotiable, especially for the demanding conditions in the UAE and KSA.

- Current Range: Ensure it covers the highest and lowest currents you expect to measure.

- True-RMS: Mandatory for accurate readings on VFDs, electronic ballasts, or any modern power supplies.

- Safety Rating (CAT): The rating (e.g., CAT IV 600V) must match the highest-risk environment you will be working in. Never use an underrated meter.

- Environmental Protection (IP Rating): In the GCC, an IP54 rating or higher is critical for durability against dust and moisture.

Consider Value-Added Features

Finally, consider features that can make your job faster, safer, or easier.

Pro Tip: Focus on the total cost of ownership, not just the initial price. A durable, reliable meter with time-saving features like data logging offers a better long-term return on investment.

Powerful additions to consider:

- Inrush Current Measurement: Essential for diagnosing nuisance breaker trips and sizing motor protection.

- Data Logging: Invaluable for tracking intermittent faults or monitoring energy usage over time.

- Low Impedance (LoZ) Mode: Eliminates "ghost" voltages from adjacent live wires, preventing false readings.

- Flexible Current Probes: Allows measurement on oversized busbars or in tight spaces where rigid jaws won't fit.

By using this checklist, you can invest in a clamp meter that is accurate, safe, and robust enough for professional use across the UAE. For personalized advice, the experts at GoSwitchgear are ready to support your project needs.

Frequently Asked Questions

Here are answers to common questions from engineers, electricians, and panel builders across the UAE and GCC.

Why Is a True-RMS Clamp Meter So Important for My Work in the UAE?

Modern electrical systems in the UAE are filled with non-linear loads like VFDs, LED lighting, and server rooms, which create distorted AC waveforms. A standard 'averaging' meter can produce readings with up to 40% error on these waveforms. A True-RMS clamp meter has the advanced processing to accurately calculate the real power value, regardless of waveform distortion, which is critical for accurate diagnostics and system safety.

What Is the Real Difference Between CAT III and CAT IV?

CAT ratings are about personal safety, indicating a meter's ability to withstand a transient overvoltage.

- CAT III is for three-phase distribution systems, such as commercial lighting, switchgear, and large motors inside a building.

- CAT IV is for measurements at the power source, like utility service entrances and main distribution panels.

For most work on building distribution systems in Dubai, a meter rated at CAT III 1000V or CAT IV 600V is the minimum. If your job involves the utility's power source, CAT IV is mandatory.

How Do I Measure Current on a Busbar Too Large for My Meter's Jaw?

Never attempt a partial clamp, as the reading will be inaccurate and the practice unsafe. The correct tool is a flexible current probe, often called a Rogowski coil. This flexible loop wraps around large or awkwardly shaped conductors and plugs into your clamp meter, allowing you to safely and accurately measure very high currents (often up to 3000A) in spaces where rigid jaws cannot fit.

For expert help selecting the right testing instruments or any electrical components UAE projects require, the team at GoSwitchgear is here to help. Reach out to our Dubai team for project support.

You can explore our full lineup of professional-grade tools and solutions at https://goswitchgear.ae.

Leave a Reply