Mastering Electric Vehicle Charging Installation in the UAE: A Guide for Engineers & Panel Builders

A successful electric vehicle charging installation in the UAE and GCC requires more than just connecting wires. For engineers and panel builders, it is a complex project demanding a strategic blueprint that addresses the region’s unique climate and strict regulatory landscape. From site assessment to final commissioning, a deep understanding of local standards is essential to deliver a safe, reliable, and durable energy management solution in Dubai and beyond.

Your Blueprint for EV Charger Installation in the UAE

The rapid growth of electric mobility across the UAE presents a significant opportunity for engineers, electricians, and procurement specialists. To transform this opportunity into a successful project, a structured approach adapted to the GCC's climate and regulatory challenges is non-negotiable.

Whether the project is a commercial hub in Dubai or a residential complex in Abu Dhabi, a solid plan is the starting point. This roadmap helps avoid common pitfalls, such as selecting electrical components that cannot withstand extreme heat or failing to secure approvals from authorities like DEWA or ADDC. Understanding broader concepts like Electric Vehicle Fleet Management provides valuable insight into operational demands, informing infrastructure choices from the outset.

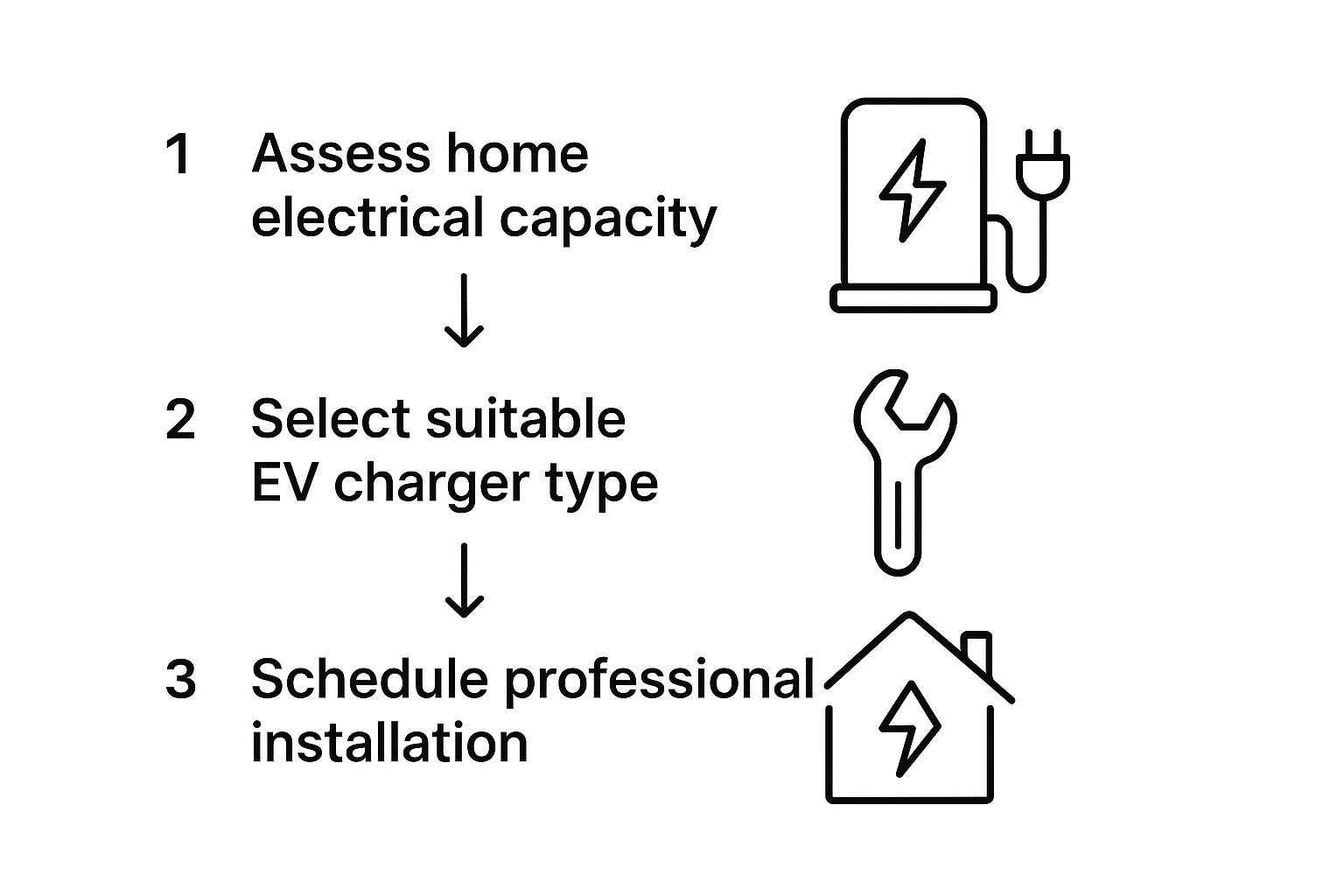

Core Phases of a UAE EV Charging Installation Project

A methodical approach is the foundation of any successful installation. The table below breaks down the essential stages, objectives, and critical considerations for any project in the UAE and wider GCC, serving as a field guide for anticipating challenges.

Core Phases of a UAE EV Charging Installation Project

| Installation Phase | Primary Objective | Critical UAE & GCC Considerations |

|---|---|---|

| Site Assessment & Load Analysis | Determine project feasibility, electrical capacity, and the best spot for the chargers. | Check existing panel loads, especially during peak HVAC use. You must account for extreme ambient temperatures (50°C+) and the impact of direct sun on equipment. |

| Component Selection & Procurement | Choose chargers, switchgear, and protective devices that are safe and built to last in this climate. | Look for components with high IP ratings (like IP65) for dust and moisture protection. Prioritise equipment with proven thermal management and IEC/GCC certification. |

| Installation & Wiring | Physically install everything according to the approved engineering designs and safety rules. | Use correctly sized, heat-resistant cabling to prevent derating in high temperatures. Robust earthing and the right RCD (Type B for EV chargers) are non-negotiable. |

| Regulatory Approval & Commissioning | Get the official sign-off from local authorities and confirm the whole system works as it should. | Prepare meticulous documentation for DEWA/ADDC submissions. Be ready to perform thorough testing, from insulation resistance to functional safety checks. |

By following a structured process, every critical aspect is addressed, from initial design to final handover.

Key Takeaway: A successful electric vehicle charging installation in the GCC is a holistic process. Climate resilience, strict regulatory compliance, and meticulous planning must be integrated from the start to guarantee a safe, efficient, and durable system.

Conducting a Thorough Site Assessment and Load Analysis

A professional electric vehicle charging installation is won through meticulous groundwork. A proper site assessment and load analysis form the foundation, preventing costly overloads, ensuring regulatory compliance, and building a reliable system that withstands the demands of the UAE and GCC climate.

This process is a forensic examination of a building's electrical system. Before any hardware is ordered, engineers and electricians must assess the main distribution board (MDB) and any relevant sub-main distribution boards (SMDBs).

Evaluating Existing Electrical Infrastructure

A common mistake is to only consider the total connected load. It is crucial to analyse the building's maximum demand by reviewing historical energy data, particularly during peak usage times—typically hot afternoons when air conditioning systems run at full capacity. Adding EV chargers to an already strained system can lead to nuisance tripping or equipment damage.

A hands-on assessment should include checking for:

- Available Breaker Slots: Confirm physical space for new circuits.

- Busbar Capacity: Ensure existing busbars can handle the continuous load from EV charging without overheating.

- Condition of Components: Look for signs of stress such as overheating, corrosion, or ageing breakers and wiring.

This evaluation determines if the current setup can handle the new load or if upgrades, such as a panel replacement or a new supply from the local utility, are required.

Calculating Electrical Load for Different Scenarios

Load calculation varies by project scale and type.

For a single-family villa in Abu Dhabi, the full load of a 7.4kW or 11kW AC charger is typically added to the home's existing load. It is best practice to plan for the worst-case scenario: the vehicle charging during peak household consumption.

A multi-charger commercial hub in Dubai requires a more nuanced approach. Instead of simply summing the ratings of all chargers, diversity factors are applied. An office building might see 40-50% of chargers active simultaneously, while a busy shopping mall car park could experience higher concurrent usage.

Expert Insight: For any installation with multiple chargers, a load management system is essential. These smart systems dynamically adjust power to each charger based on the building's total real-time demand, preventing overloads while maximising charging availability.

Identifying the Optimal Charger Location

Choosing the right spot for the charger balances user convenience, technical feasibility, and the harsh local environment. The ideal location minimises the cable run from the electrical panel to reduce voltage drop and material costs.

In the GCC, environmental protection is critical:

- Direct Sunlight: Avoid installing chargers in direct sun, which can cause overheating and power derating. Covered parking or a simple canopy is essential.

- Dust and Humidity: The charger and its enclosure must have a high IP rating (e.g., IP65) to protect against fine dust and moisture. Avoid proximity to irrigation systems or areas subject to pressure washing.

Determining the site's electrical capacity is the critical first step. The principles of load calculation are universal, and a deep understanding of master power supply considerations for other systems can provide valuable parallels. A detailed site assessment creates the blueprint for a safe and efficient installation.

Selecting Climate-Proof Components for Peak Reliability

In the GCC, the climate is an active stressor on electrical systems. A successful electric vehicle charging installation depends on hardware engineered to perform in extreme heat and dusty conditions. For engineers and procurement teams, this means prioritising components with superior thermal management, robust environmental protection, and full certification from local utilities like DEWA and ADDC.

This approach ensures an installation is not just compliant but fundamentally resilient.

Differentiating Between AC and DC Charger Applications

The choice between AC Level 2 and DC Fast Charging dictates the project's scope, budget, and electrical infrastructure demands.

- AC Level 2 Chargers (7kW – 22kW): Ideal for long-dwell locations like residential villas, office car parks, and hotels. They use standard AC power, making them simpler to integrate into existing electrical systems, provided a load analysis confirms sufficient capacity.

- DC Fast Chargers (50kW+): Designed for speed, these are found at public charging hubs and fleet depots. They require a powerful three-phase supply and often necessitate significant electrical upgrades, representing a more complex and capital-intensive project.

Sourcing components for a quick recharge station for electric models involves different considerations than for slower overnight chargers, and every component in the circuit must be selected accordingly.

Why High IP Ratings and Thermal Management Are Non-Negotiable

In the UAE and KSA, fine dust and high humidity can corrode sensitive electronics, while intense sun can cause component failure.

Expert Takeaway: For any outdoor or exposed EV charging equipment in the GCC, an IP65 rating is the absolute minimum. This ensures the enclosure is sealed against dust and resistant to low-pressure water jets, protecting critical components.

Thermal management is equally important. Chargers and switchgear generate heat, which, combined with high ambient temperatures, creates a risk of system failure. Always select chargers with active cooling and specify switchgear rated for operation at 50°C or higher without derating. Enclosures require proper ventilation, and for larger installations, dedicated cooling solutions like those discussed in our guide on selecting the right panel cooling fan are advisable.

Specifying Compliant Switchgear for Local Utility Standards

The switchgear is the system's silent protector. Specifying the correct protective devices is crucial for both safety and regulatory approval. Every component must meet the stringent standards of local authorities. The right "electrical components UAE" suppliers, like GoSwitchgear, provide certified, high-quality hardware.

The EV charging market in the Middle East is projected to reach USD 1,437.7 million by 2030, driven by the need for reliable infrastructure. This growth demands that every installation is built with certified, top-tier components, including quality energy meters and an effective energy management solution Dubai.

Essential Component Selection for the UAE Climate

The following table details essential electrical components and their recommended specifications for reliability in the UAE's demanding climate.

| Component | Recommended UAE Specification | Why It Matters | GoSwitchgear Example |

|---|---|---|---|

| Moulded Case Circuit Breaker (MCCB) | Thermal-magnetic trip unit rated for 50°C ambient temperature. | This prevents nuisance tripping caused by high ambient heat, providing reliable overcurrent and short-circuit protection when it's actually needed. | GoSwitchgear MCCBs are engineered for high-temperature performance, guaranteeing stability under GCC conditions. |

| Residual Current Device (RCD) | Type B RCD with a 30mA sensitivity rating. | Type B is mandatory for EV chargers. It detects the smooth DC fault currents that standard Type A RCDs can't see, which is a critical safety feature. | Our range includes IEC 61851 compliant Type B RCDs, ensuring the highest level of protection for EV installations. |

| Surge Protection Device (SPD) | Type 2 SPD installed at the sub-distribution board. | This shields the sensitive electronics in both the charger and the vehicle from voltage spikes caused by lightning or grid fluctuations. | We offer robust Type 2 SPDs specifically designed to handle the electrical transients common in the region's power grid. |

| Enclosure | IP65 rated, powder-coated steel or GRP (Glass Reinforced Plastic). | An IP65 enclosure offers superior defence against dust, moisture, and corrosion, which dramatically extends the life of all the components inside. | GoSwitchgear provides a variety of IP65 enclosures perfect for housing control and protection devices in harsh environments. |

By selecting components based on their proven ability to handle local conditions, you transform a standard installation into a reliable, long-term asset.

Mastering Installation Wiring and Safety Protocols

This phase is where meticulous plans become a working asset. For electricians and panel builders in the UAE and GCC, installation is about precision and strict adherence to safety protocols, all while accommodating the region's unique climate.

Proper wiring ensures the system can handle continuous high loads in extreme ambient temperatures. This section covers the critical details of wiring, earthing, and on-site safety procedures that define a professional installation.

Core Wiring Principles for AC and DC Chargers

The wiring strategy differs significantly between single-phase AC chargers and high-power, three-phase DC chargers.

A standard 7.4kW single-phase AC charger requires a dedicated circuit from a distribution board. The connection is straightforward (live, neutral, and earth), but cable selection is crucial. In the UAE's high ambient heat, thermal derating must be factored in to prevent a cable that is adequate in cooler climates from becoming a hazard.

Three-phase DC fast chargers are more complex. They require a heavy-duty three-phase AC supply to feed their internal rectifier. The installation involves power lines and data communication cables for management systems. Clean cable management and proper segregation are essential to prevent electromagnetic interference.

Expert Insight: I always recommend using armoured cables (SWA) for underground runs or areas with a risk of damage. If using conduits, select a larger size to allow for heat dissipation and reduce thermal stress—a small detail with a big impact.

Common Wiring Mistakes to Avoid

Even experienced electricians can make errors during an electric vehicle charging installation. These mistakes can create safety hazards, lead to premature equipment failure, and result in a failed inspection.

Common errors include:

- Undersized Cabling: The most dangerous error. Failing to account for heat-related derating causes the cable to overheat, creating a significant fire risk. Always consult IEC guidelines and local regulations for correct sizing in high-temperature environments.

- Wrong RCD Choice: A standard Type A RCD is insufficient for EV chargers. EVs can produce smooth DC leakage currents that "blind" a Type A RCD, rendering it ineffective. Using a Type B RCD is a non-negotiable safety requirement as it is designed to detect AC, pulsating DC, and smooth DC fault currents.

- Weak Earthing: A poor earth connection is a critical safety failure. The earthing system must have a low impedance path to the ground to ensure protective devices trip instantly during a fault. Testing the earth loop impedance is a mandatory part of commissioning.

- Loose Terminations: Connections not torqued to manufacturer specifications create high-resistance points that generate heat under load, leading to terminal burnout and fire risk. A calibrated torque wrench is an essential tool.

On-Site Safety and LOTO Procedures

An installation site is an active construction zone requiring robust safety protocols. A risk assessment must be conducted before work begins.

Lockout/Tagout (LOTO) procedures are mandatory when working on electrical panels. This involves isolating the power source, physically locking the isolator in the 'off' position, and attaching a tag to indicate the circuit is under maintenance. Only the person who placed the lock should have the key to remove it, preventing accidental re-energisation.

The EV charging station market in the Middle East and Africa was valued at approximately US$162.53 million in 2024 and is projected to exceed US$380.67 million by 2029. This growth, driven by initiatives like SASCO's plan for 50 ultra-fast charging stations in Saudi Arabia, underscores the need for an unwavering commitment to safety from all engineers and electricians.

Navigating Regulatory Approvals and Final Commissioning

Mechanical installation is only half the battle. Without official approval from local authorities like DEWA (Dubai), ADDC (Abu Dhabi), or SEWA (Sharjah), an EV charging station remains a collection of unusable hardware. The final stage of regulatory approvals and commissioning is where professionalism and attention to detail are paramount.

Using high-quality, pre-approved electrical components UAE from a trusted supplier like GoSwitchgear provides a significant advantage. Inspectors recognise components that meet stringent local standards, instilling confidence in the installation's safety and reliability.

The Critical Documentation and Inspection Process

A comprehensive documentation package must be submitted and approved before an on-site inspection. This package typically includes:

- Final As-Built Drawings: Detailed single-line diagrams (SLDs) and schematics reflecting the exact installation.

- Component Datasheets and Certificates: Manufacturer's datasheets and IEC/local compliance certificates for all key components, including chargers, MCCBs, RCDs, and energy meters.

- Load Schedule: An updated load schedule for the distribution board showing the new EV charger circuit and its impact on total demand.

- Contractor and Engineer Credentials: Proof of trade licenses and accreditations.

Once the paperwork is approved, the physical inspection is scheduled. Quality workmanship, including tidy installations, clear labelling, and properly torqued connections, greatly influences the inspector's assessment. Our guide on how to conduct an electrical panel inspection offers checklists to help navigate this step successfully.

A Step-by-Step Guide to Testing and Commissioning

Commissioning is a systematic process to verify that every component and safety feature functions as intended. It must be performed and documented before handover.

The UAE's push for EV infrastructure, with goals like Vision 2030 aiming for 70,000 charging stations, leaves no room for cutting corners. This rapid growth, detailed in articles about UAE's EV charging station initiatives, means every installation must meet the highest safety standards through rigorous commissioning.

Expert Insight: Commissioning is the final opportunity to identify potential issues. A detailed commissioning report, with recorded values for every test, is the ultimate proof of a safe, professional installation.

The commissioning checklist must cover these non-negotiable tests:

- Visual Inspection: A final review of the entire installation against the approved as-built drawings.

- Continuity and Polarity Checks: Verification of all protective earth conductors and correct connection of live conductors.

- Insulation Resistance Test: A safety check using a 500V megohmmeter to ensure there are no short circuits or damaged cable insulation.

- Earth Fault Loop Impedance (Zs) Test: Confirms the earth path is sufficient to trip the circuit breaker within the required time during a fault.

- RCD Tests: Comprehensive testing of the Type B RCD to verify it trips at the correct sensitivity (e.g., 30mA) and within the specified time for both AC and DC fault conditions.

- Functional and Communication Tests: Using an EV or a dedicated simulator to confirm the charger communicates correctly, starts and stops a charge cycle, and that all safety interlocks are operational.

By meticulously navigating regulatory approvals and commissioning, you ensure a smooth project handover and deliver a system that is not only powerful but fundamentally safe.

Frequently Asked Questions

For any electric vehicle charging installation in the UAE and GCC, many questions arise due to the unique climate and strict regulations. Here are answers to common queries from engineers, electricians, and procurement teams.

AC vs DC Chargers in a Dubai Commercial Building

The primary differences between installing AC and DC chargers in a commercial setting like a Dubai office tower are power requirements, installation complexity, and cost.

AC Level 2 chargers (7kW to 22kW) are ideal for long-dwell parking (offices, residential complexes, hotels). They run on a standard three-phase AC supply, and installation is relatively straightforward, requiring a dedicated circuit from a sub-main distribution board (SMDB).

DC Fast Chargers (DCFC), starting at 50kW, are designed for speed. This comes with a significant cost and complexity, demanding a massive three-phase power supply that often requires upstream upgrades like a new transformer and heavy-duty cabling from the main distribution board (MDB). The approval process with authorities like DEWA is also more intensive.

Key Insight: The choice depends on the use case. AC chargers are for topping up over several hours. DC chargers are for rapid refuelling, ideal for public hubs or commercial fleets.

The Mandatory RCD Type for EV Charger Safety

For any EV charger installation in the UAE, a Type B Residual Current Device (RCD) is non-negotiable and the mandatory safety standard.

An electric vehicle's on-board charger can produce smooth DC leakage currents during a fault, which a standard Type A RCD cannot detect. This can "blind" the RCD, preventing it from tripping during a fault. A Type B RCD is specifically designed to detect the full spectrum of fault currents (AC, pulsating DC, and smooth DC). Installing anything other than a certified Type B RCD violates IEC 61851 standards and creates a serious safety risk.

How GCC Heat Influences Installation Practices

The GCC's extreme heat is a critical design factor. Ambient temperatures exceeding 50°C can severely impact the performance and lifespan of electrical equipment.

- Component Selection: Choose chargers with active thermal management (e.g., internal fans) to prevent overheating. Switchgear must be rated for high ambient temperatures to avoid nuisance trips. This includes components like a DIN rail isolator or an SMPS power supply.

- Enclosure and Placement: Outdoor enclosures need a high IP rating (IP65 is a good benchmark) and should be installed in shaded, well-ventilated locations to avoid direct sun.

- Cable Sizing: Heat reduces a cable's current-carrying capacity. Account for this derating by using larger conductor sizes than in cooler climates to safely handle the continuous load.

The Need for a Dedicated Commercial Energy Meter

For commercial installations where billing for electricity is required, a dedicated, MID-certified energy meter GCC standard is essential for accurate billing and regulatory compliance.

While many smart chargers have built-in metering, some billing platforms or project specifications may require an external, utility-grade meter in the distribution panel for an undisputed record of energy consumption.

For private homes, a separate meter is not mandatory but highly recommended. Our guide on installing an electric car charger at home provides more detail. An external meter allows homeowners to track their EV's energy usage separately from household consumption, providing a clear picture of running costs.

For expert support on your next EV charging project in Dubai, Abu Dhabi, or across the UAE, trust GoSwitchgear to provide certified, climate-resilient solutions. Our team is ready to assist with everything from component selection to commissioning support.

Explore our full range of electrical components and get a quote for your project

Leave a Reply