Selecting the Right Electrical Cable Gland in the UAE: A Practical Chart & Guide

For engineers, panel builders, and procurement teams across the UAE, selecting the right electrical components is critical for project safety and reliability. This guide provides a clear electrical cable gland chart to simplify selection for projects in Dubai, Abu Dhabi, and the wider GCC, ensuring your installations withstand the region’s demanding climate.

Why Cable Gland Selection is Critical for UAE & GCC Projects

In the extreme heat, humidity, and dust common across the GCC, a cable gland is more than a simple accessory. It is the frontline defense for your electrical system's integrity, preventing contamination and providing essential mechanical stability. For any professional working in the UAE's booming infrastructure sector, from engineers to electricians, choosing the correct electrical components UAE specifiers trust is non-negotiable.

The demand for high-quality components is soaring. The Middle East cable gland market was valued at USD 40.31 million and is on a clear growth path. You can review the complete market research on this growth for more details.

The Definitive Electrical Cable Gland Sizing Chart

This section provides a practical, go-to electrical cable gland chart designed for the real-world demands of projects across the UAE and GCC. No guesswork, no "close enough"—just the right fit for a secure, compliant, and properly sealed connection every time.

The process is simple: match your cable's overall diameter (OD) to the correct metric gland size. To ensure project teams consistently use the latest specifications, many firms implement document version control best practices.

Metric Cable Gland Sizing Chart

Use this table to match your cable's overall diameter (OD) to the correct metric (M) thread cable gland for a secure, IP-rated seal.

| Metric Gland Size | Cable OD Range (mm) | Common Applications in UAE |

|---|---|---|

| M12 x 1.5 | 3 – 6.5 | Small sensors, control wiring, LED lighting fixtures |

| M16 x 1.5 | 4 – 8 | Standard control panels, small junction boxes, instrumentation |

| M20 x 1.5 | 6 – 12 | General-purpose power & control cables, small motors, pumps |

| M25 x 1.5 | 13 – 18 | Main power feeds for small machinery, distribution boards |

| M32 x 1.5 | 18 – 25 | Larger motor connections, sub-main panel incomers |

| M40 x 1.5 | 22 – 32 | Feeder cables for distribution units, heavy-duty equipment |

| M50 x 1.5 | 32 – 38 | Main panel incomers, large industrial machinery connections |

| M63 x 1.5 | 37 – 44 | Transformer connections, main switchgear, heavy industrial feeds |

This chart is a reliable starting point for most common applications. For an even more detailed, interactive tool, use the complete GoSwitchgear interactive https://goswitchgear.ae/cable-gland-size-chart/ on our website to ensure a perfect fit for every installation.

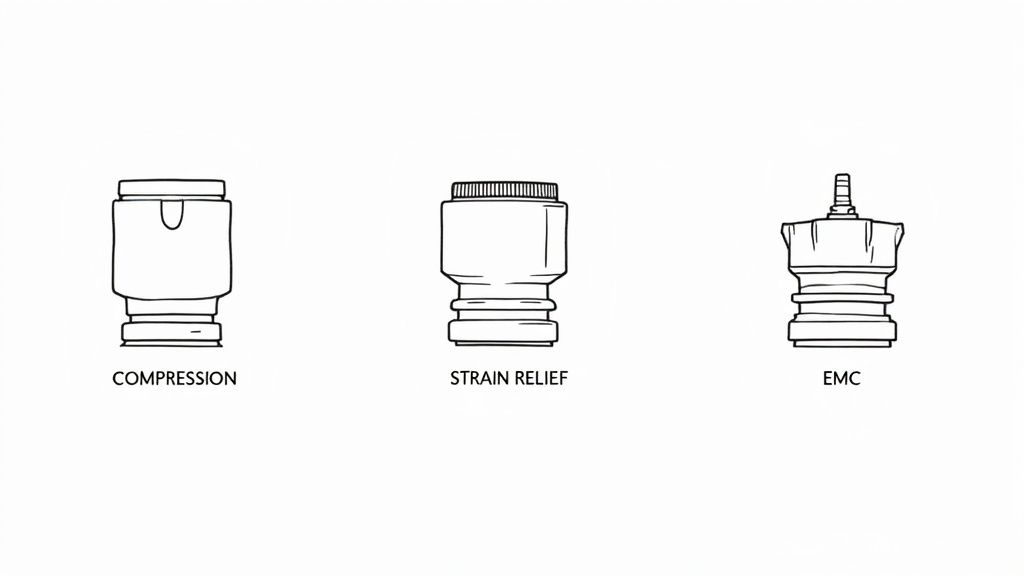

Choosing the Right Gland Type and Material

Selecting the correct size from an electrical cable gland chart is only the first step. For an installation to endure the GCC's demanding climate, the material and gland type are crucial. The choice between brass, stainless steel, or nylon directly impacts how well the fitting resists corrosion, heat, and mechanical stress.

- Nickel-Plated Brass: The workhorse for most industrial applications in Dubai and Abu Dhabi. It’s tough, reliable, and cost-effective.

- Grade 316 Stainless Steel: Essential for highly corrosive environments, such as coastal projects with salt spray or chemical processing plants.

- EMC Glands: Required for sensitive control systems to shield against electrical interference.

- Explosion-Proof (Ex-d) Glands: Non-negotiable for hazardous areas, particularly in the UAE’s oil and gas sector.

Getting these material and type specifications right from the start is what separates a safe, long-lasting installation from one destined for premature failure.

Understanding Metric and NPT Thread Standards

Mismatched threads are a common but critical mistake that can compromise an entire electrical system. In the UAE and across the GCC, you will primarily encounter two thread standards: Metric (M) and National Pipe Thread (NPT).

- Metric (M) Threads: These are parallel and require a sealing washer or O-ring to achieve a proper IP-rated seal. They are the dominant standard in the region.

- NPT Threads: These are tapered. As they are tightened, the threads wedge together, creating a tight seal through an "interference fit." They are often found on equipment from North America.

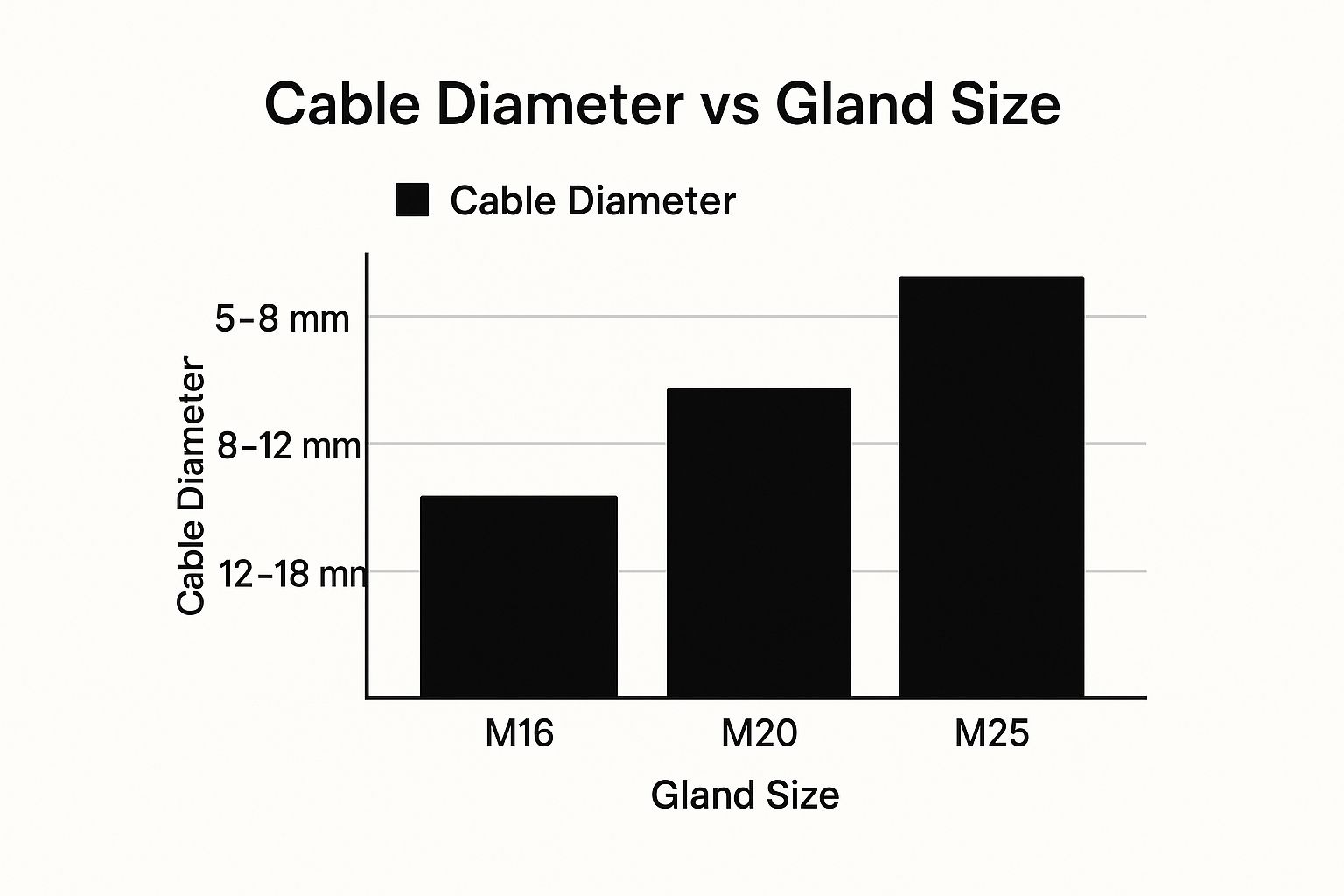

This chart provides a quick visual guide for selecting the right gland based on cable diameter.

Correctly matching the gland to the cable diameter ensures you maintain IP ratings and achieve a mechanically sound connection every time.

Metric vs NPT Thread Comparison

This table offers a clear, side-by-side comparison to ensure you specify the correct thread for your equipment and enclosures, a key step in finding a reliable energy management solution Dubai projects require.

| Attribute | Metric (M) Thread | NPT Thread |

|---|---|---|

| Thread Form | Parallel (straight) threads. | Tapered threads. |

| Sealing Method | Requires a separate sealing washer or O-ring to create an IP-rated seal. | Self-sealing; the tapered design creates a seal as threads are tightened. |

| Primary Standard | ISO Metric Screw Thread (ISO 68-1). The dominant standard in the GCC and Europe. | ANSI/ASME B1.20.1. The dominant standard in the United States and Canada. |

| Common Use Case | Widely used for panel building, machinery, and enclosures in the UAE. | Often found on equipment from North America, especially in process control. |

| Installation Note | Tighten until the washer/O-ring is compressed. Overtightening can damage the seal. | Tighten to create a friction seal. Thread sealant is often recommended. |

Crucially, these thread types are not interchangeable. Always double-check equipment specifications to ensure a perfect match and avoid a weak, unsealed connection.

Ensuring Proper IP Ratings for the GCC Climate

The GCC environment is defined by fine dust, intense humidity, and scorching heat. For this reason, the Ingress Protection (IP) rating on your cable glands is non-negotiable. This rating, found on any professional electrical cable gland chart, indicates how well a gland protects against solids (dust) and liquids (water).

Skimping on the IP rating leads to premature equipment failure and creates serious safety risks. With major industries like oil and gas in the UAE and Saudi Arabia, glands must meet stringent IP standards to handle these extreme conditions. This concept applies to many components; learn more in our guide on IP-rated switches and sockets for industrial use in the UAE.

Best Practices: Cable Gland Installation and Common Mistakes

Selecting the right part from an electrical cable gland chart is only half the battle. A perfect, IP-rated seal depends entirely on proper installation.

Common Installation Mistakes to Avoid

One of the most frequent and damaging mistakes is improper tightening.

- Over-tightening: Crushes the cable's inner bedding and destroys the seal.

- Under-tightening: Leaves the assembly vulnerable to dust and moisture, rendering the IP rating useless.

Other critical errors include:

- Using mismatched components: Never force a gland for unarmoured cable onto an armoured one. They are engineered for different purposes.

- Incorrect sizing: Always measure the cable's Overall Diameter (OD) accurately. Do not estimate.

- Forgetting the sealing washer: This small component is essential for metric glands to achieve a watertight and dust-tight seal.

Your Go-To Partner for Electrical Projects in the UAE

Correct cable gland selection is a critical step in building robust and compliant electrical systems. The MEA wire and cable market reached USD 25.1 billion in 2023, underscoring the region's massive demand, as detailed in this regional cable market research.

GoSwitchgear is your technical partner in the field, stocking a complete range of high-quality glands specifically chosen to withstand the local climate. For a deeper dive into other crucial electrical components, such as a DIN rail isolator or an SMPS power supply, explore our technical resources like this guide on understanding electrical transducers.

Our teams in Dubai and Abu Dhabi are ready to provide expert support for your next project.

Got Questions About Cable Glands? We've Got Answers.

Here are answers to common questions we hear from engineers and electricians working on projects across the UAE.

Do I Really Need a Different Gland for Armoured vs. Unarmoured Cable?

Yes, absolutely. This is a fundamental safety requirement. An armoured cable gland (e.g., for SWA cable) is designed with a mechanism to clamp the armour, providing critical mechanical strength and ensuring earth continuity. Using a standard gland on an armoured cable is a serious safety hazard, as it fails to secure the cable or ground the armour properly. An electrical cable gland chart will always differentiate between types.

What's the Point of a Cable Gland Shroud?

A cable gland shroud is a push-on cover, typically made of PVC, that adds an extra layer of protection. In the harsh outdoor environments common in the GCC, a shroud shields the gland assembly from corrosive dust, moisture, and direct sunlight, extending the life of the termination and ensuring long-term reliability.

Which Certifications Should I Look for in the UAE?

Certification is your assurance of safety and performance.

- IEC 60529: Look for this standard for IP ratings against dust and water ingress in general industrial applications.

- ATEX or IECEx: These certifications are mandatory for hazardous areas, which are common in the region's oil and gas sector. Using uncertified components in these zones is a risk you cannot afford to take.

For expert guidance and a full range of certified cable glands suited for the UAE climate, contact our Dubai team or explore the extensive catalogue from GoSwitchgear at https://goswitchgear.ae.

Leave a Reply