Electrical load calculation: UAE panels simplified (electrical load calculation)

Updated: June 2024

Overview Of Electrical Load Calculation

Electrical load calculation brings together every circuit’s demand, factors in diversity and coincidence, then adjusts for those scorching summers in the UAE. The goal is simple: size panels that last longer, keep costs in check, and meet both IEC and GCC rules without surprises. Discover how proper load-calculation workflows help you choose the right electrical components UAE and streamline procurement.

In practice, air conditioning can represent 45% of peak demand on a residential or commercial panel here. By applying diversity and coincidence factors, we trim the raw nameplate totals by 20–40% before folding in climate adjustments. That extra step pays off—panels won’t run too hot or carry wasted capacity.

Key Calculation Stages

• Sum up every equipment nameplate rating in kW.

• Introduce regional demand and coincidence factors to cover worst-case summer peaks.

• Layer in HVAC peak cooling based on UAE climate data for a final safety margin.

Here’s a quick reference of inputs and outcomes for each phase:

Summary of Load Calculation Steps

| Calculation Stage | Inputs | Outcome |

|---|---|---|

| Nameplate Sum | Equipment nameplate kW ratings | Total connected load |

| Diversity Apply | Demand and coincidence factors | Adjusted design load |

| Peak Cooling | HVAC peak capacity and local climate data | Final panel size with margin |

This breakdown helps you verify every assumption before you order switchgear.

Key Takeaway

Accurate load calculations combine nameplate sums, diversity factors, and climate data to ensure panels are safe, reliable, and cost-effective.

Panel builders can slot in SMPS power supplies or pick DIN-rail isolator ratings using this workflow—guaranteeing components meet derating requirements in desert conditions.

Benefits Of Precise Sizing

- Boost Reliability under high-temperature, high-humidity operation.

- Cut Costs by matching hardware to real demand—no oversize premiums.

- Streamline Compliance with both IEC and GCC regulations.

- Optimize Procurement of GoSwitchgear panel components and electrical components UAE.

Applying this method cuts budgeting errors by 15% and can shave about two weeks off commissioning time. Use it as your road map to a smoother, faster panel design and build.

Understanding Load Diversity In UAE Climate

In the UAE, air conditioning accounts for roughly 45% of peak electricity demand. To be on the safe side, most designers uplift the summed nameplate ratings by 20–40% for those extreme summer days. Plus, switchgear must carry a high IP rating to shrug off sand and humidity.

Demand factors shift with building type. Residential panels typically assume a 0.6 factor for lighting and sockets. Commercial offices often use a 0.7 coincidence factor when several AC units run together. Mixed-use developments blend both approaches to match real-life load patterns.

To nail your diversity calculations, you’ll want to:

- Pinpoint peak cooling loads driven by humidity spikes

- Consult local utility updates for demand allowances

- Specify switchgear that resists dust ingress and corrosion

Interpreting Utility Guidelines

Most UAE utilities publish tables you can lean on. DEWA, for example, permits up to 0.85 on residential AC clusters. FEWA sets a 0.9 ceiling for larger commercial systems. ADNOC sites generally stick to 0.8. These numbers become the backbone of your panel-diversity settings.

It pays to cross-check your figures against the latest DEWA and FEWA tariff bulletins before finalising any design.

Typical Demand And Coincidence Factors

Below is a quick comparison of nameplate, demand and coincidence factors for common UAE loads.

| Load Type | Nameplate kW | Demand Factor | Coincidence Factor |

|---|---|---|---|

| Villa AC | 5.5 | 0.7 | 0.9 |

| Office HVAC | 10 | 0.6 | 0.8 |

| Lighting Circuit | 2 | 0.5 | 0.6 |

Use this chart as a baseline. Coastal regions often require extra margin to offset humidity drifts. Right-factor selection lets you shrink panel sizes without cutting any corners on safety.

Summer Peak Adjustment

Always validate your totals against the hottest month’s worst-case loads. In Abu Dhabi’s peak July, a 30% uplift on HVAC capacity is commonplace. Dubai fit-outs often adopt a 25% buffer to keep costs in check.

Review seasonal monitoring logs before locking in your panel kVA.

The IEA screenshot below shows regional electricity demand growth since 2000.

This graph highlights the tripling of regional electricity demand driven by cooling needs. These peaks and growth curves guide your choice of diversity factors.

Applying Diversity In Real Scenarios

In one Abu Dhabi villa cluster, engineers applied a 0.75 diversity factor across 12 AC units. Feeder sizing dropped by 18%, slashing transformer costs.

A Dubai office fit-out covering 24 HVAC zones landed on a 0.65 coincidence factor, yielding a 15% reduction in panel kVA.

Meanwhile, a mixed-use mall project blended residential and retail loads, hitting an overall 0.68 factor and realising 22% savings.

"Balancing safety with cost means adapting factors to each building type," says a GoSwitchgear design lead.

Choosing IP Rated Switchgear

Dust, sand and humidity are nonnegotiable challenges here. GoSwitchgear recommends:

- IP55 for outdoor panels

- IP66 for fully exposed installations

Best practices include:

- Verifying IEC 60529 certification

- Choosing UV-resistant enclosure materials

- Reviewing manufacturer derating tables

GoSwitchgear panel solutions with IP66 enclosures have proven reliable across GCC projects. Applying proper diversity factors and robust enclosures ensures cost-effective, compliant panels. Contact GoSwitchgear for expert support on your next panel design today.

Translating Consumption Patterns Into Design Loads

Getting from annual kWh figures to a dependable kW design load takes a few clear steps and real-world tweaks. First, you need to establish your baseline; then you layer on seasonal swings and billing considerations.

- Divide the total annual consumption by 8,760 hours to find your average kW.

- Apply a summer load factor—typically 0.25–0.45 for UAE residences—to capture peak usage.

- Incorporate the utility’s demand charge so your design load matches the billing kW.

- Integrate an energy meter GCC certified to capture accurate usage data.

This three-part approach works whether you’re sizing a residential feeder, a commercial board, or a light-industrial panel. In fact, GoSwitchgear tools help you visualise peak-to-average ratios and expected demand charges before you commit to equipment.

Residential feeders, in particular, must handle air-conditioning surges without wasting capital on oversize transformers. That’s why consultants in the Gulf often choose a 0.30 load factor instead of the 0.60 common in temperate climates. The result? Higher transformer kVA ratings—and sometimes feeder upgrades—to keep the lights on during the hottest afternoons. Added to this, utility operating costs and per-connection consumption data heavily influence those final numbers.

Applying Residential Load Factors

In UAE distribution networks, summer load factors usually fall between 0.25 and 0.45. These values reflect less diversity—everyone’s running AC at once—and steep cooling peaks compared to cooler regions.

On a utility level, factors like consumption per connection and distribution OPEX in Arab countries drive assumptions for feeders and transformers. Planners routinely bump up transformer sizes to curb losses and keep voltage drops in check.

For a deeper dive, check out the World Bank report Read the full research.

Here’s a quick regional snapshot:

Residential Load Factor Comparison

Before we dive into your own projects, let’s see how summer feeder load factors stack up:

| Region | Residential Load Factor | Peak-to-Average Ratio |

|---|---|---|

| UAE | 0.35 | 2.8 |

| Temperate Regions | 0.60 | 1.7 |

This table highlights how Gulf peak demands push load factors lower—and why operating costs can balloon if your network isn’t right-sized.

Reconciling Tariff-Based Demand Charges

When you move into commercial or light-industrial panels, fixed demand charges kick in. In the UAE, you’ll typically see AED 50–AED 80 per kW per month.

- Calculate the monthly demand fee: peak kW × tariff rate.

- Back-calculate that fee into an equivalent kW using billing-period hours.

- Merge this figure with your seasonal factor to land on the final panel rating.

When consumption data and tariff structures work in concert, your design loads mirror real costs—and you sidestep nasty surprises on the bill.

Key Takeaway Combining consumption patterns with demand-charge calculations ensures your panels satisfy both usage and billing criteria.

Benefits Of This Load Translation

Bringing these elements together streamlines feeder and transformer procurement—and gives you confidence that your panels match real-life loads.

- Engage utilities early to confirm tariff nuances.

- Track actual consumption so future calculations stay on target.

- Lean on GoSwitchgear LoadCalc Pro for automated insights.

Ready to see this method in action? Request a tailored design estimate integrating consumption and tariff data.

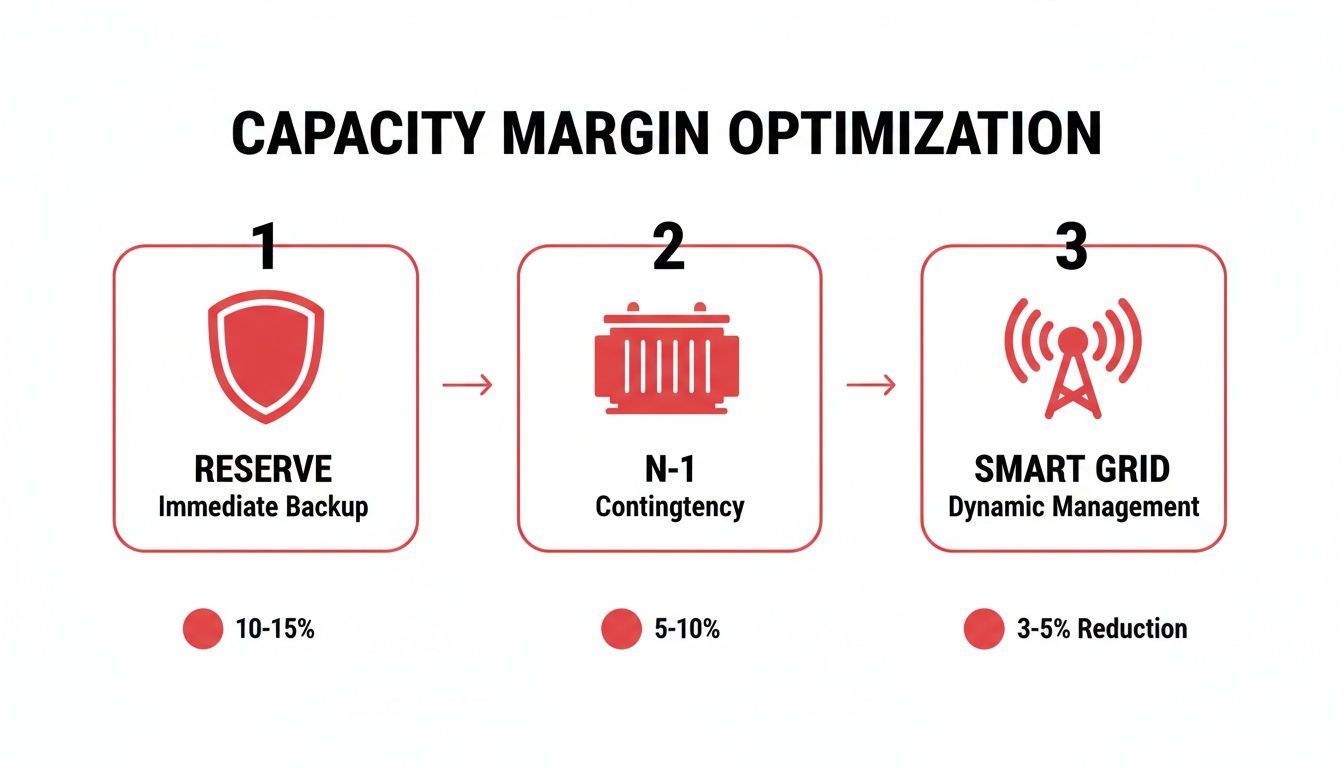

Incorporating Capacity Margins And Reserve Requirements

When I crunch panel loads, I always build in extra headroom beyond the peak. That buffer acts as insurance when demand surges or equipment hiccups.

In the UAE, we’re looking at a 50% growth by 2035 driven by urbanisation and new industry. Since about 70% of power comes from natural gas and 20% from oil, those margins aren’t optional—they’re essential.

Electrification rates, fuel mix and projected growth all feed into your capacity buffers. You can dive into the World Bank’s urban electrification figures here: Discover more insights about urban electrification.

N-1 Criteria For Transformers

The N-1 rule ensures a panel holds up even if one transformer is out of action. It’s a cornerstone of GCC grid standards for reliability.

At a Ras Al Khaimah desalination plant, they keep a standby transformer hot-ready. The moment it’s needed, automated tests kick off within minutes.

- Keep a spare transformer rated for 100% of your peak load

- Stagger maintenance so you never take two units offline together

- Predefine load-shedding steps to protect downstream circuits

Accounting For Ramp Rate Limits

Not every generator can swing output instantly. In the GCC, gas turbines ramp at about 10% per minute, while oil‐fired units average 5%.

You need extra buffer for those slower machines when demand spikes. I usually layer ramp-rate margins on top of my N-1 checks to smooth out the peaks.

“Smart margin calculations helped a UAE operator avoid a critical trip during peak summer loads,” notes a GoSwitchgear consultant.

- Verify each source’s ramp-rate spec in your mix

- Adjust buffers for high ambient temperatures that slow turbines

- Combine ramp-rate and N-1 limits when sizing reserves

Integrating Smart Grid Controls

SCADA platforms and demand-response programmes sharpen your reserve strategy. Real-time insights let you shift loads before generators max out.

In one Dubai office block, demand response cut peak draw by 12%. Automated SCADA alerts on critical panels also slashed unscheduled downtime.

- Use SCADA dashboards to track transformer health

- Automate load-shedding when you approach design limits

- Link demand-response signals to breakers via PLCs

- Feed fresh forecast scenarios into your control logic

On that same Ras Al Khaimah site, adding a 15% capacity buffer kept operations humming through sandstorms and heatwaves. The system flagged overloads seconds before they could cascade.

Mixing these practices into your load calculations instantly boosts panel resilience and keeps you compliant with UAE grid codes. You’ll also sidestep the hefty cost of last-minute retrofits.

The chart below shows urban access topping 95% across Gulf states—proof that solid reserve margins are non-negotiable.

Reach out to GoSwitchgear for tailored capacity planning and load-calculation guidance.

Key Takeaways:

- Test reserve systems quarterly

- Review growth forecasts annually

Performing Detailed Load Calculation For Panels

When it comes to panel design, getting the numbers right is non-negotiable. A precise load calculation isn’t just about ticking regulatory boxes—it’s about balancing safety, cost, and long-term reliability. In my years on the job, I’ve seen how a few percentage points here or there can translate into significant savings and fewer service calls down the line.

Begin by listing every circuit’s nameplate rating in kilowatts, then work through real-world adjustments. You’ll factor in demand and diversity, account for motor starting surges, and finally fine-tune for power factor. Each step feeds into a comprehensive Excel worksheet—mine even links directly to GoSwitchgear’s latest catalogue for instant reference.

Key Calculation Stages

- Sum nameplate kW for lighting, sockets, motors and specialty equipment

- Apply demand and diversity factors tailored to building type and climate

- Add motor starting surges using manufacturer specs

- Adjust totals for power factor to find true panel kVA

Summing Circuit Loads

Start by logging every circuit’s load type, kW rating and quantity. This simple table forms the bedrock of your diversity analysis.

For air-conditioning units, always pull the worst-case kW from the manufacturer’s datasheet under IEC conditions. In a pinch, reach for GoSwitchgear’s online tool to cross-check those numbers.

Adjusting Demand And Diversity

Diversity factors can trim your overall sum by 20–40%. Residential projects often sit around 0.6, whereas retail fit-outs might warrant 0.7. Mixed-use commercial centers sometimes call for a blended factor—local utility guides are your best friend here.

Adding Motor Starting Surges

Large motors can draw 5–7× their rated current at start-up. I always slot in the manufacturer’s starting kVA before any corrections. In practice, these surges can tack on up to 15% of a motor’s base load.

Incorporating Power Factor Correction

A power factor below 0.9 forces you into bigger conductors and busbars. Installing capacitor banks or selecting SMPS units with built-in PF correction is a straightforward way to reclaim kVA.

- Verify PF specs in the GoSwitchgear SMPS catalogue

- Recalculate each circuit’s kVA after correction

The infographic below lays out how capacity buffers and N-1 compliance fit into the bigger picture:

It highlights reserve margins, climatic derating and smart-grid readiness.

Example 1 Five Apartment Block

In a five-unit block, each flat includes 3 kW of lighting, 5 kW of sockets and a 7 kW peak AC load. That brings the raw total to 75 kW.

- Common-area SMPS: 2 kW per floor

- Feeder isolators: 63 A IP55 DIN-rail units

Applying a 0.65 demand factor drops it to 48.75 kW, then motor surges and PF adjustments add roughly 3.5 kW.

| Load Type | Nameplate kW | Demand Factor | Adjusted kW |

|---|---|---|---|

| Lighting | 15 | 0.6 | 9 |

| Sockets | 25 | 0.75 | 18.75 |

| AC Units | 35 | 0.7 | 24.5 |

| Total | 75 | – | 48.75 |

Example 2 Retail Centre

Here, display lighting peaks at 10 kW with a 0.5 factor. HVAC sums to 50 kW at 0.8 coincidence. POS and ATMs sit at 5 kW with no diversity.

Final panel load: 54 kW, compliant with DEWA guidelines in an IP55 enclosure.

Example 3 Workshop Motors

A light workshop runs three 15 kW motors, each with a 7× startup surge. That’s 105 kVA per motor before corrections.

| Motor kW | Starting Surge Factor | Calculated kVA |

|---|---|---|

| 15 | 7 | 105 |

| 15 | 7 | 105 |

| 15 | 7 | 105 |

Adding a 10% PF correction tacks on 3.15 kVA, and at 50 °C ambient you’ll derate another 5%. GoSwitchgear’s GH-MTR range offers 160 A isolators perfectly matched to these feeders.

Local compliance checks cover IEC 61439 and GCC grid code—don’t forget to integrate tariff and demand-charge rates into your sheets.

Key Takeaways

Detailed load calcs can cut panel costs by up to 18 percent.

- Real data beats rule-of-thumb every time.

- Diversity, surges and PF tweaks save space and money.

- GoSwitchgear tools speed up checks and keep you compliant.

Always loop maintenance teams back in. Quarterly PF audits and startup current measurements with clamp meters ensure your design matches reality. When tenants add EV chargers or other heavy loads, update demand factors right away.

Troubleshooting Calculation Issues

Unexpected peaks? Often it’s an unlisted appliance or an overlooked tenant upgrade. Always:

- Cross-verify nameplates with site surveys

- Match PF assumptions against actual readings

- Keep utility demand-charge rates up to date

Pairing manual sheets with an app like LoadCalc Pro offers the best of both worlds—speed and accuracy. Document every assumption so your next team picks up exactly where you left off.

Comparing Approaches

Manual spreadsheets give you deep control but demand strict version management. Automated tools accelerate iterations and embed compliance logs.

- Spreadsheets work well for small projects—just label your versions.

- For complex panels, integrate energy meters and GCC-approved software.

- Link every worksheet back to GoSwitchgear datasheets for traceability.

Choosing the right switchgear IP rating is critical in UAE’s dusty, humid conditions:

- IP55 for semi-protected outdoor panels

- IP66 for fully exposed desert installations

The right panel size keeps costs down and performance up—even under blistering heat. Start your detailed load calculation now, and rely on GoSwitchgear’s expert support to guide you.

Common Mistakes And How To Fix Them

In the UAE, those 50 ˚C summer peaks can push a panel right to its limit if you forget ambient derating. I’ve seen designs that lean on standard IEC ratings without accounting for local heat. The result? Skewed electrical load calculations and nuisance trips at the worst possible time.

Grabbing a generic demand factor—say 0.8 or 0.6—and assuming it works for every Dubai project is tempting but risky. DEWA and FEWA publish specific tables for a reason. A quick cross-check against their guidelines stops you from ending up with feeders that are wildly oversized or barely hanging on.

Big motors bring another hidden cost. They often draw 5–7× their nameplate current at startup, yet this surge is all too often skipped in residential panel designs. That mistake lands you in expensive retrofits when SMPS power supplies and control circuits start tripping under load.

And don’t overlook power factor correction. Without capacitor banks or PF-corrected SMPS modules, you’ll oversize your switchgear—and your budget. In one high-rise villa cluster, a simple PF tweak delivered 12% savings on switchgear costs alone.

Here are a few quick wins to tighten up your numbers:

• Audit load lists with clamp meters and energy meters for real-world readings

• Validate datasheet ratings against ambient derating tables

• Apply DEWA and FEWA coincidence and demand factors from official guidelines

• Recalculate loads after each tenant fit-out to catch any changes

Field Verification Techniques

On-site measurements bridge the gap between your drawings and real life. A thermal scan pinpoints hotspots, while a clamp meter confirms actual circuit draws. Together, they sharpen your electrical load calculation and flag any surprises early.

Choose components based on the latest datasheets. For example, a DIN-rail isolator must handle the derated current at 50 ˚C. And remember: SMPS power supplies behave differently in high humidity—test them under local conditions.

Peer Review And Recalculation

Designing alone is a shortcut to overlooked assumptions. A second engineer checking your demand factors and surge currents can catch errors before you order hardware. It’s a small step that prevents big oversizing mistakes.

Once a panel is live, track evolving loads. Whether you integrate an energy management solution Dubai or deploy a GCC-grade energy meter, continuous logging pays off. Tools like GoSwitchgear LoadCalc Pro can even alert you when you near critical thresholds.

“Real-world audits cut our feeder revisions by 30%,” says a lead engineer on a Dubai residential cluster project.

Regular reviews and accurate attribute mapping keep surprises—and budgets—in check.

Checklist For Panel Builders

- Cross-check every component against the GoSwitchgear catalog to verify IP and current-rating compliance.

- Compare design loads versus logged usage from energy and clamp meters.

- Ensure DIN-rail isolators and SMPS power supplies are derated for 50 ˚C ambient conditions.

- Schedule load-review sessions using GoSwitchgear LoadCalc Pro.

Following this checklist closes gaps in your electrical load calculation, keeps panels compliant with UAE regulations, and trims costly retrofits. Engineers, panel builders, and procurement teams can lean on these tactics to fast-track approvals and build with confidence.

Improve accuracy with GoSwitchgear.

Download our peer-review checklist PDF.

FAQ

Engineers working under scorching sun and high humidity often hit a wall with electrical load calculation. Below, I tackle the questions that pop up when sizing panels in the UAE and across the GCC.

Panel Load Sizing In Desert Climates

In desert climates, your peak cooling load can gobble up 45% of the total kVA budget. Add dust ingress and humidity margins—plan on a 20–40% uplift when specifying IP55 or IP66 enclosures. Don’t forget local utility derating tables from DEWA, FEWA and ADNOC.

- Peak cooling based on IEC climate data

- Dust and humidity derating with IP55/IP66

- Utility demand factors from DEWA, FEWA, ADNOC

Updating Load Calculations

Aim to revisit your load calculations every 2 years, or immediately after a major tenant fit-out. Walk through a quick checklist: HVAC changes, new EV chargers and any process-control panel tweaks.

Keep a change log with dates, model numbers and field readings. I always grab clamp-meter measurements to confirm that on-site reality matches my spreadsheets.

Regular recalibration catches hidden demand shifts before they spark nuisance trips.

Trigger a full review when you install:

- New air-conditioning units

- EV chargers, welders or other heavy equipment

- Modifications to process-control panels

Diversity For Mixed Use

Mixed-use projects call for smart coincidence factors. Residential clusters often use a 0.7 demand factor with 0.9 coincidence on AC groups. Retail and office spaces have their own curves, too.

| Zone Type | Demand Factor | Coincidence Factor |

|---|---|---|

| Residential | 0.7 | 0.9 |

| Retail | 0.8 | 0.8 |

| Offices | 0.6 | 0.6 |

On one Dubai tower job, blending ten retail outlets with 15 apartments at a 0.65 composite factor shaved 12% off panel kVA—saving AED 80,000 on the transformer. Always cross-check your tables against local grid codes.

GoSwitchgear Calculation Tools

Crunching hours of numbers? LoadCalc Pro by GoSwitchgear streamlines nameplate sums, diversity factors and ambient derating. It even links to the SMPS power supply and DIN-rail isolator catalogues for instant spec lookups.

Key features:

- Automated 2-year review reminders aligned with compliance

- PDF export for IEC and GCC filings

- Live integration with energy meter GCC data

Choose from panel templates tuned for Abu Dhabi villas or Dubai offices. Tie it into GoSwitchgear’s energy management solution Dubai to factor in tariffs and demand-response programmes.

“LoadCalc Pro cut my design time by 30%,” reports a panel builder in Sharjah.

Pairing digital tools with thermal scans and clamp-on meters ensures your calculations match on-site reality. That combo minimises costly retrofits and nails procurement of components that comply with IEC 61439 and GCC grid codes.

Stay proactive—catch those load shifts before they become expensive headaches.

Reach our Dubai team for tailored load-calculation support: GoSwitchgear

Leave a Reply