Choosing the Right MCCB Circuit Breaker for UAE & GCC Projects

In complex electrical systems, a Moulded Case Circuit Breaker (MCCB) acts as a critical safeguard. Built for high-power circuits, this automatic switch protects valuable equipment from overcurrents and short circuits. For engineers and panel builders in the UAE, selecting the right MCCB circuit breaker is a foundational step for ensuring electrical safety and operational continuity in a demanding climate.

Why the Right MCCB is Mission-Critical for UAE Infrastructure

In the high-demand environment of the UAE and wider GCC, a reliable power supply is the backbone of economic activity. From Dubai's iconic skyscrapers to Saudi Arabia's sprawling industrial zones, every operation depends on stable electricity. An MCCB circuit breaker is the vigilant gatekeeper ensuring that stability.

An MCCB’s primary role is to differentiate between normal operating currents, harmless inrush from motor start-ups, and dangerous faults like overloads or short circuits. When a genuine fault is detected, it trips automatically, cutting power before it can cause equipment damage, electrical fires, or costly downtime. This is a critical function for any energy management solution in Dubai.

Safeguarding High-Value Assets and Operations in the GCC

The financial impact of an electrical failure in this region can be severe. An unexpected outage can halt a manufacturing line, disrupt critical financial services, or compromise essential infrastructure, leading to significant losses.

A correctly specified MCCB delivers:

- Equipment Protection: It shields expensive machinery, transformers, and switchgear from burnout caused by overcurrents.

- Operational Continuity: By isolating faults, it prevents a localized issue from cascading into a system-wide failure, minimizing downtime.

- Personnel Safety: It significantly reduces the risk of severe electrical shock and life-threatening arc flash incidents.

The growing emphasis on robust protection is reflected in market trends. The Middle East's MCCB market was valued at approximately USD 649.3 million in 2023 and continues to expand. This growth is driven by the region's rapid development and increasing energy demands, highlighting the trust placed in these essential electrical components UAE relies on. You can explore the full research on MCCB market growth.

A correctly specified MCCB is not an expense; it is an insurance policy against the immense costs of electrical failure. It’s the silent protector that ensures the lights stay on and industries keep running across the GCC.

The table below provides a snapshot of an MCCB's key protective roles and its common applications across the UAE.

MCCB Functions and Common UAE Applications

| Core Function | What It Protects Against | Typical UAE Application |

|---|---|---|

| Overload Protection | Gradual, sustained overcurrents from overloaded equipment or wiring. | Commercial buildings (HVAC systems), retail malls, residential towers. |

| Short-Circuit Protection | Sudden, massive current surges from direct faults (e.g., phase-to-phase contact). | Industrial manufacturing plants, oil and gas facilities, large-scale construction sites in KSA. |

| Manual Switching | Allows for safe, manual disconnection of a circuit for maintenance or emergencies. | Data centers, hospitals, and any facility requiring planned maintenance shutdowns in Dubai. |

This table underscores how an MCCB’s versatility makes it indispensable, from protecting everyday commercial operations to securing the GCC's most critical industrial assets.

For engineers and procurement teams in the UAE, selecting the right MCCB is a decision with significant consequences. It requires a deep understanding of electrical loads, the challenging local climate, and strict regulatory compliance. GoSwitchgear offers a comprehensive range of high-quality MCCBs designed to meet these specific challenges, providing a solid foundation of safety and reliability for your projects.

How an MCCB Works to Stop a Disaster in Its Tracks

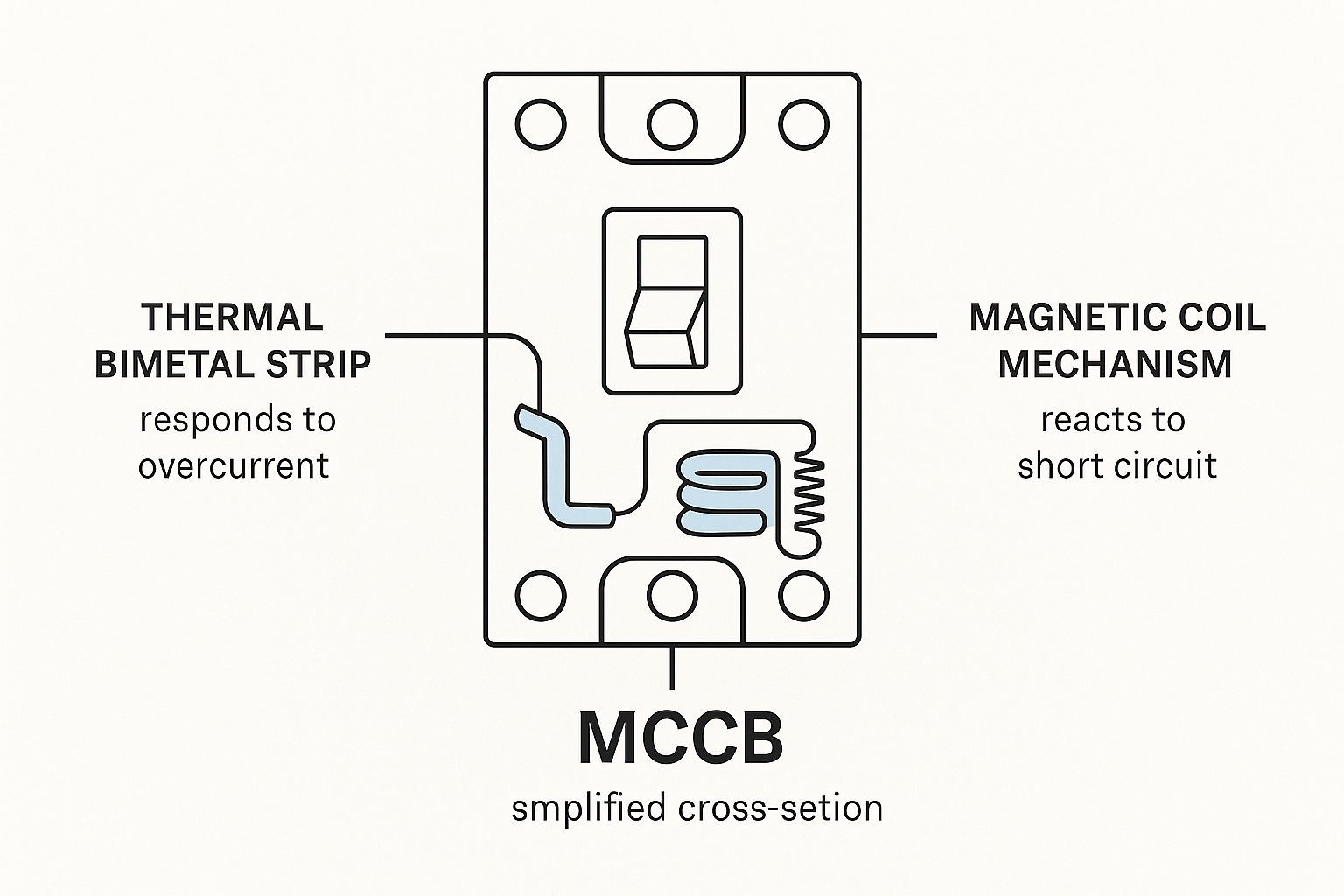

To appreciate why an MCCB circuit breaker is so critical for major projects in the UAE, it's essential to understand its internal workings. It is more than a simple switch; it's an intelligent, self-contained protection device with three key components working in unison: the trip unit, the operating mechanism, and the arc extinguisher. Each part is designed to detect danger and neutralize it before it causes damage.

The trip unit is the MCCB’s brain. It constantly monitors the electrical current, looking for signs of trouble. This brain employs two distinct defense mechanisms to tackle different types of electrical threats.

The Two Lines of Defense: Thermal and Magnetic Trips

The first line of defense is the thermal trip, which acts as the patient guardian against slow-burning overloads. It uses a bimetallic strip—two different metals bonded together that expand at different rates when heated.

When a circuit is overloaded, the excess current heats this strip, causing it to bend. If the overload persists, the strip bends enough to engage the trip bar, which releases the internal switch and opens the circuit. This deliberate, time-delayed action prevents "nuisance trips" from temporary inrush currents (like when a large motor starts), while reliably stopping sustained overloads that could melt wiring.

The second line of defense is the magnetic trip. This is the fast-acting sentinel that responds instantly to catastrophic short circuits. This mechanism uses a simple electromagnet. Under normal conditions, the current flowing through its coil is insufficient to create a strong magnetic force.

However, during a short circuit, the current can skyrocket to hundreds or thousands of times its normal level. This surge creates a powerful magnetic field that instantly pulls an armature, striking the trip bar with force. The reaction is nearly instantaneous—measured in milliseconds—cutting power before the immense energy release can cause fires or explosions.

The image below illustrates this dual-protection system, showing how the thermal and magnetic components work together inside the MCCB.

This simplified diagram highlights how the slow-acting bimetal strip and the lightning-fast magnetic coil provide a complete safety net for different types of electrical faults.

The Crucial Role of Arc Quenching

When an MCCB trips under a massive fault current, its contacts separate. The electricity doesn't simply stop; the immense energy attempts to jump the air gap, creating a brilliant, intensely hot plasma known as an electrical arc. This arc can be hotter than the sun's surface, capable of melting metal, destroying insulation, and igniting devastating fires.

This is where the arc extinguisher, or arc chute, demonstrates its value. It is one of the most critical safety features in an MCCB, especially in high-power industrial settings.

An uncontrolled electrical arc is one of the most dangerous phenomena in power systems. Safely extinguishing it within milliseconds is what separates a minor trip from a major disaster.

The arc chute is a chamber containing a stack of parallel metal plates. As the arc forms, the powerful magnetic field from the fault current forces it into this chamber. The plates slice the single, powerful arc into a series of smaller, weaker arcs. This process rapidly cools the plasma and increases its electrical resistance, effectively "stretching" and "starving" the arc until it is extinguished.

This entire quenching process is completed in a fraction of a second, safely containing the fault's destructive energy within the MCCB's housing. This is a primary reason why a robust MCCB circuit breaker is non-negotiable for protecting assets and personnel in demanding commercial and industrial environments across the GCC.

Choosing the Correct MCCB Type for Your Project

Selecting the right MCCB circuit breaker is a critical decision for the safety and uptime of any electrical system. It is not a one-size-fits-all component. The optimal choice for a commercial tower in Dubai will differ significantly from the requirements of an industrial plant in Saudi Arabia.

Making the correct selection requires a clear understanding of trip characteristics, trip unit technology, and core electrical parameters.

Let's review the essential criteria to confidently specify an MCCB that meets both your project's technical demands and local UAE utility standards.

Understanding Trip Characteristics

An MCCB's trip curve defines its response to different levels of overcurrent. The objective is to prevent nuisance trips during normal operations while ensuring instantaneous action during a genuine fault. MCCBs are typically categorized based on their magnetic trip setting.

- Type B: Trips at 3 to 5 times its rated current (In). Ideal for resistive loads like water heaters or simple lighting circuits with no significant inrush current.

- Type C: Trips at 5 to 10 times the rated current (In). This is the workhorse for most commercial and light industrial applications in the GCC, providing a balance for circuits with moderate inrush currents from small motors or fluorescent lighting.

- Type D: Trips at a much higher 10 to 20 times the rated current (In). This type is essential for heavy-duty industrial applications involving large motors, transformers, and heavy machinery with high start-up currents.

Thermal-Magnetic vs. Electronic Trip Units

The MCCB's "brain," or trip unit, is available in two main types: traditional thermal-magnetic and modern electronic. This choice significantly impacts protection accuracy and system intelligence.

Thermal-Magnetic MCCBs are the industry standard. They use a bimetallic strip for slow-building overloads and an electromagnet for short-circuit protection. They are rugged, reliable, and cost-effective, making them a solid choice for straightforward applications with fixed settings.

Electronic Trip Unit MCCBs offer a superior level of precision and control. They use microprocessors for current monitoring, enabling highly customizable protection.

An electronic trip unit transforms a simple protective device into an intelligent data hub for a modern electrical network. This is absolutely vital for the smart building systems we're seeing more of in Dubai and Abu Dhabi.

Key advantages of electronic trip units include:

- Adjustable Settings: Engineers can fine-tune long-time, short-time, and instantaneous trip settings to create a precise protection envelope for the specific load.

- Enhanced Accuracy: They are less sensitive to ambient temperature fluctuations—a major benefit in the hot GCC climate, reducing the risk of false trips.

- Communication Capabilities: Many models integrate with Building Management Systems (BMS) or SCADA, enabling remote monitoring, data analysis, and predictive maintenance.

Key Electrical Parameters for Selection

Beyond the trip type, several fundamental electrical ratings must be correctly specified for safety and compliance. For a closer look at different models, feel free to browse our full catalog of electrical protection equipment.

These three parameters are absolutely critical:

- Rated Current (In): The maximum current the MCCB can carry continuously without tripping. It must be higher than the circuit's normal operating current but lower than the cable's ampacity.

- Ultimate Breaking Capacity (Icu): This rating indicates the maximum fault current the MCCB can interrupt without catastrophic failure. This value must be higher than the prospective short-circuit current (PSCC) at the point of installation.

- Rated Voltage (Ue): The MCCB's voltage rating must match or exceed the system voltage. An under-rated MCCB cannot properly extinguish an electrical arc during a fault.

Selecting an MCCB for the Demanding GCC Climate

The GCC’s climate—characterized by extreme heat, high humidity, and pervasive dust—presents a uniquely challenging environment for electrical components. These are not minor inconveniences; they are severe stressors that test the limits of performance and reliability.

When selecting an MCCB circuit breaker, these local conditions are critical variables. They directly affect performance, long-term reliability, and safety. Simply matching electrical specifications from a datasheet is insufficient; you must consider how the device will behave at 50°C amid high humidity and dust.

The growing focus on robust circuit protection is no surprise. As industrialization and infrastructure projects continue across the UAE and KSA, the market for reliable electrical components has seen significant growth. MCCBs have proven their worth by protecting critical low-voltage systems in some of the world's toughest environments.

The Critical Concept of Temperature Derating

The primary challenge in the GCC is heat. Ambient temperatures in the UAE frequently exceed 40°C and can reach 50°C. This poses a significant problem for standard thermal-magnetic MCCBs.

These breakers contain a bimetallic strip that heats up and bends to trip the mechanism during an overload. However, this strip is also affected by the ambient air temperature. On a scorching Dubai afternoon, the strip is already pre-heated, meaning it requires less load current to reach its tripping point. This leads to "nuisance tripping" on circuits that are not genuinely overloaded.

To counteract this, we apply temperature derating.

Derating is the process of intentionally reducing the current-carrying capacity of an MCCB to account for high ambient temperatures. Not doing this in the GCC is a common and dangerous oversight.

This adjustment ensures the MCCB circuit breaker trips only when it should. Manufacturers provide derating curves or tables to simplify this calculation. For example, a 100A breaker rated at 40°C might only handle 85A at an ambient temperature of 50°C.

Here is a sample guide for derating an MCCB in high ambient temperatures.

MCCB Derating Guide for High Ambient Temperatures

This table shows sample derating factors for a standard MCCB based on ambient temperatures typical in the UAE, helping you select the correct rating.

| Ambient Temperature (°C) | Nominal Rated Current (In) | Derated Operational Current | Correction Factor |

|---|---|---|---|

| 40°C (Standard) | 100A | 100A | 1.00 |

| 45°C | 100A | 95A | 0.95 |

| 50°C | 100A | 90A | 0.90 |

| 55°C | 100A | 85A | 0.85 |

| 60°C | 100A | 80A | 0.80 |

Always consult the manufacturer’s datasheet for the specific model you are using to ensure technical accuracy.

Protection Against Dust and Moisture: The Importance of IP Ratings

Fine desert dust and coastal humidity in cities like Dubai and Abu Dhabi pose another major threat. Dust can infiltrate the internal mechanics of a breaker, obstructing the trip mechanism. Moisture can cause corrosion and create conductive paths, leading to insulation failure and fire hazards.

This is where Ingress Protection (IP) ratings are essential. An IP rating indicates how well an enclosure protects its internal components from solids (like dust) and liquids (like moisture).

- For an indoor panel in a clean, air-conditioned environment, IP4X may suffice.

- For outdoor installations or dusty industrial floors, a higher rating like IP54 or IP65 is necessary to ensure the breaker remains protected and functional.

Choosing a properly rated enclosure from a trusted supplier like GoSwitchgear is as crucial as selecting the right breaker. This is why a multi-layered defense is so critical for a resilient energy management solution in Dubai. Combining a properly derated MCCB with a high-IP-rated enclosure provides a robust setup capable of withstanding the GCC climate.

Best Practices for MCCB Installation and Commissioning

Selecting the right MCCB circuit breaker is just the first step. Its performance and safety ultimately depend on professional, standards-compliant installation. For any panel builder or electrician in the UAE, proper installation and commissioning are crucial for the long-term integrity of the electrical system.

It begins with secure mounting. The MCCB must be firmly fastened to the panel's back plate or DIN rail, where applicable. Any vibration can loosen terminal connections over time, creating a significant failure point. Stable mounting is fundamental to mechanical and electrical reliability.

Equally important is providing adequate clearance. MCCBs generate heat during operation, a factor exacerbated by the high ambient temperatures in the GCC. Crowding the breaker traps heat, which can lead to nuisance tripping or thermal damage. Always adhere to the manufacturer’s specified minimum clearance distances.

Securing Connections and Preventing Overheating

A large percentage of electrical faults originate from poor connections. Therefore, achieving the correct terminal torque is one of the most critical installation tasks.

Under-torqued terminals create high-resistance hot spots that can melt insulation and ignite a fire. Conversely, over-torquing can strip the screw, damage the conductor, or crack the breaker's housing, compromising the connection's integrity.

Always use a calibrated torque wrench to tighten each terminal to the exact Newton-meter (Nm) value specified in the MCCB's datasheet. This simple action is a powerful safeguard against future failures.

The Commissioning Checklist: Final Verification

Once the MCCB is installed, it must be properly commissioned before the circuit is energized. This final verification process ensures the breaker and circuit are safe, compliant, and ready for service, meeting the strict standards of local authorities like DEWA or ADDC.

Your commissioning workflow should include these essential checkpoints:

-

Visual and Mechanical Inspection:

- Verify that the MCCB's ratings (Amps, Volts, Icu) match the project drawings.

- Inspect for any physical damage from shipping or handling.

- Confirm all terminal connections are correctly torqued.

- Ensure the enclosure has the correct IP rating for the environment.

-

Insulation Resistance Test:

- Often called a "Megger" test, this step verifies the health of the cable and MCCB's internal insulation. It detects low-resistance paths to ground that could indicate damaged insulation or moisture.

-

Contact Resistance Test:

- Using a Ductor or micro-ohmmeter, measure the resistance across the breaker's main contacts when closed. A high reading may indicate internal issues like dirty or pitted contacts, which can cause overheating under load.

-

Trip Functionality Test:

- This is the final verification. Using a primary current injection test set, a controlled fault current is passed through the MCCB. This test proves that both the thermal and magnetic trip mechanisms operate within the time and current specifications on the manufacturer’s trip curve. It is the ultimate confirmation that your MCCB circuit breaker will perform its protective function when it matters most.

By following these installation and commissioning steps, you ensure an electrical installation that is not only safe and compliant but also robust enough to provide reliable protection for years.

MCCB Maintenance and Troubleshooting for UAE Facilities

A high-quality MCCB circuit breaker is designed for longevity, but its reliability depends on proactive maintenance. For facility managers and engineers in the UAE, a robust maintenance and troubleshooting plan is essential for ensuring operational continuity and protecting assets from catastrophic failure. A well-maintained MCCB is a predictable one.

Regular maintenance is the first line of defense against the harsh environmental conditions of the GCC. The combination of dust, humidity, and extreme temperatures creates a challenging environment for electrical equipment. Consistent maintenance prevents these factors from degrading your breaker's protective capabilities.

Routine Inspection and Maintenance Schedule

A consistent maintenance schedule can significantly extend an MCCB's service life and prevent unplanned shutdowns. This schedule should be tailored to the specific conditions of your site, whether a data center in Dubai or an industrial facility in Abu Dhabi.

A practical maintenance routine includes:

- Visual Inspections (Quarterly): Check the MCCB housing for signs of overheating, such as discoloration or charring. Look for cracks or other physical damage. This simple walk-through can reveal serious underlying issues.

- Cleaning (Annually): Dust is a persistent issue in the region. Use a vacuum or a clean, dry, lint-free cloth to remove accumulated dust and debris from the breaker and its enclosure. This prevents contaminants from interfering with the mechanical trip mechanism.

- Connection Re-Torquing (Annually or as per manufacturer): Loose connections are a common fire hazard. Thermal cycling can cause terminal connections to loosen over time. Use a calibrated torque wrench to ensure every connection is tightened to the manufacturer’s specifications.

An MCCB that is regularly cleaned, inspected, and tested is significantly less likely to fail. This simple discipline is one of the most effective ways to ensure facility-wide electrical safety and reliability.

Common MCCB Problems and Solutions

Even with diligent maintenance, issues can arise. Knowing how to diagnose common problems allows for faster resolution and reduced downtime. The following table outlines frequent issues, their likely causes, and recommended actions.

| Common Problem | Potential Causes | Recommended Action |

|---|---|---|

| Nuisance Tripping | – Sustained Overload: The circuit is drawing more current than its rating. – High Ambient Temperature: Heat is derating the breaker, causing premature tripping. – Incorrect Trip Settings: Electronic trip units may be set too sensitively. |

– Verify Load: Use a clamp meter to measure the actual current draw. – Check Ventilation: Ensure the panel has proper cooling. – Review Settings: Adjust electronic trip unit settings to match the load profile. |

| Failure to Trip | – Mechanical Jamming: Dust, debris, or internal damage is obstructing the mechanism. – Welded Contacts: A severe past fault has fused the internal contacts. – Incorrect Sizing: The breaker is oversized for the circuit's fault level. |

– Manual Test: Carefully operate the breaker handle. If it feels stuck, do not force it. – Professional Testing: The breaker must be de-energized and tested by a qualified technician using current injection equipment. – Immediate Replacement: If contacts are welded or the mechanism is jammed, the MCCB must be replaced immediately. |

For a deeper dive into asset care, our comprehensive maintenance and troubleshooting guide delivers additional expert insights specifically for UAE facilities. Ultimately, proactive management of your MCCB circuit breaker inventory is the cornerstone of a resilient and safe electrical system.

Got Questions About MCCBs? We’ve Got Answers.

When it comes to projects across the UAE and GCC, we field a lot of questions from our engineering and procurement clients about the molded case circuit breaker (MCCB). To clear things up and help you make better decisions, we've put together answers to some of the most common queries we hear.

What's the Real Difference Between an MCCB and an MCB?

The simplest way to think about it is capacity and control. An MCB (Miniature Circuit Breaker) is your standard protection for smaller circuits, usually handling anything under 100A. You'll find them everywhere, guarding final distribution circuits for things like lighting and small appliances.

An MCCB, on the other hand, is the heavy-hitter. It’s built for much higher currents, typically starting from 100A and going all the way up to 2500A. The big advantage? Many MCCBs come with adjustable trip settings. This allows engineers to perfectly tailor the protection to the specific load, like a large motor or a main distribution board—a level of fine-tuning you just don't get with an MCB.

How Do I Figure Out the Right Breaking Capacity for My Project?

This is non-negotiable and requires precision. The required breaking capacity (often listed as Icu or Ics) absolutely must be higher than the maximum prospective short-circuit current (PSCC) at the exact spot where the breaker will be installed. This isn’t a number you can guess; it has to be determined by a qualified electrical engineer who performs a proper fault level study.

Don't ever cut corners here. Installing an MCCB with an insufficient breaking capacity is a major safety hazard. If a short circuit happens that's stronger than the breaker's rating, it can fail violently, causing an explosion and a dangerous arc flash.

Can I Just Use an MCCB from Another Country in the UAE?

We strongly advise against this unless the device has been explicitly certified for the region's tough environmental conditions and meets local standards. MCCBs used in the UAE and the broader GCC have to perform reliably in very high ambient temperatures, which often means they need to be derated.

Even more importantly, they must comply with regulations from local authorities like DEWA and ADDC. Using a non-compliant breaker doesn't just void its warranty; it puts your entire facility at risk. This is precisely why there's such a strong regional market for certified electrical components. In fact, the Middle East and Africa's electrical protection market, which includes MCCBs, was valued at USD 2.11 billion in 2024 and is set to grow. You can learn more about the factors driving this regional market expansion.

For expert help in selecting the right MCCB for your specific needs in Dubai, Abu Dhabi, or across the KSA, reach out to our team for project support. The specialists at GoSwitchgear offer a full range of certified electrical components built for the unique demands of the GCC.

Explore our full range of circuit protection solutions at GoSwitchgear

Leave a Reply