How to Choose Motion Detectors for Lights in the UAE Climate

In the demanding commercial and industrial environments of the UAE and wider GCC, optimising energy consumption while ensuring robust security is a critical challenge for any project. Motion detectors for lights offer a powerful energy management solution in Dubai, automating lighting to significantly reduce waste and enhance facility safety.

Tackling Energy and Security Challenges in the UAE

For engineers, panel builders, and procurement teams across the region, specifying the right electrical components in the UAE is crucial to project success. Lighting often represents a substantial portion of operational expenses in facilities from Dubai to Abu Dhabi. Unoccupied corridors, warehouses, and offices left illuminated not only inflate utility bills but also increase a company's carbon footprint—a key concern in line with the UAE's Net Zero 2050 goals.

Conversely, inadequate lighting can create security vulnerabilities and safety hazards. Manual lighting control across large facilities is inefficient and unreliable. This guide details how motion detectors provide a practical solution to these issues, contributing to smarter, safer, and more cost-effective buildings.

We will cover:

- Core Sensor Technologies: Understanding the functional differences between sensor types.

- GCC Climate Suitability: Selecting components resilient to extreme heat, humidity, and dust.

- Installation Best Practices: Ensuring optimal performance and avoiding false triggers.

By the end of this guide, you will have the technical knowledge to integrate this energy-saving solution into your next project. For hands-on support with electrical components in the UAE, explore the GoSwitchgear catalogue.

How Motion Detector Technology Actually Works

To specify the correct motion detectors for lights for a project in the UAE, it is essential to understand the underlying technology. At their core, these devices sense presence to activate a response—typically switching on a light. The primary differentiator lies in how they detect that presence.

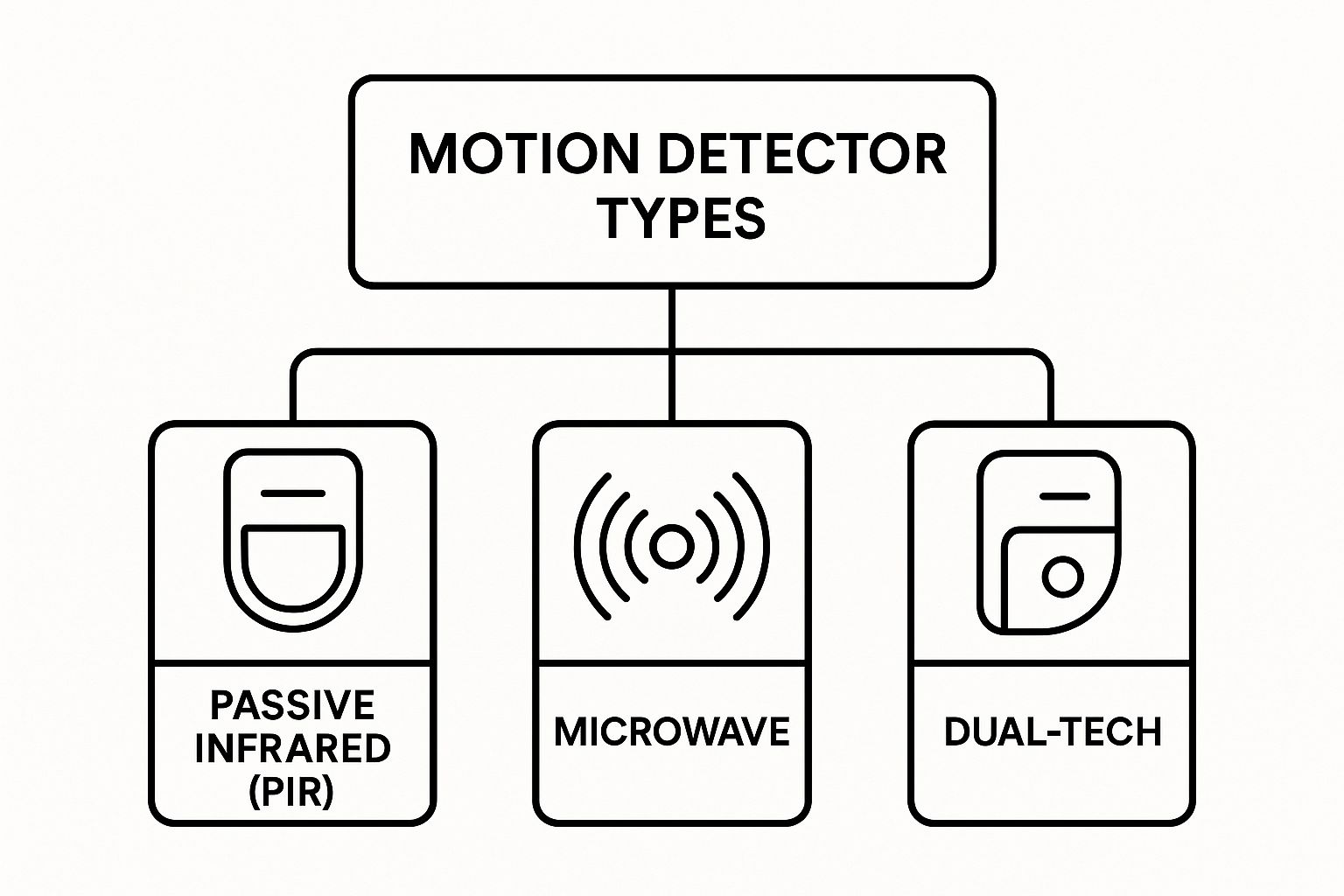

Three main technologies dominate the market, each with distinct operational principles and ideal applications. A clear understanding of these is the first step toward designing a reliable system.

Passive Infrared (PIR) Sensors

The most common and cost-effective option is the Passive Infrared (PIR) sensor. As its name implies, a PIR sensor is passive; it does not emit energy. Instead, it detects infrared energy (heat) from objects in its field of view.

Every object with a temperature above absolute zero, including people, emits heat as infrared radiation. A PIR sensor uses a segmented lens to create a grid of detection zones. When a warm body moves from one zone to another, the sensor detects this rapid change in infrared energy and triggers the connected load.

- Best For: Defined spaces such as offices, hallways, and small storage rooms with a clear line of sight.

- GCC Consideration: PIR sensors can be sensitive to rapid temperature fluctuations. In the hot UAE climate, it is critical to install them away from HVAC vents or windows where direct sunlight can cause false activations.

Microwave (MW) Sensors

Conversely, Microwave (MW) sensors are active devices. They operate like a small radar system, continuously emitting low-power microwave signals and analysing the "echo" that reflects off objects.

The sensor measures the time interval for the reflected signal to return. When an object moves within the detection zone, it disrupts the signal pattern and alters the echo time. The sensor registers this change and activates the lighting circuit.

Microwave sensors offer superior sensitivity and can cover larger areas than PIR sensors. Their signals can penetrate non-metallic materials like thin walls, glass, and plastic, making them ideal for irregularly shaped rooms or spaces with obstructions like cubicles.

Dual-Technology Sensors

For critical applications where false alarms are unacceptable, Dual-Technology (PIR + MW) sensors provide the highest level of reliability. These units combine both technologies, requiring simultaneous triggers from both the PIR and MW sensors before activating the lights.

This dual-check mechanism is invaluable in demanding GCC environments, virtually eliminating false activations caused by environmental factors like drafts of hot air. This advanced technology is fueling growth in the wireless sensor market, which is projected to expand at a CAGR of 15.6% over the next five years in the Middle East and Africa, driven by smart city initiatives. You can read more about the wireless sensor market growth in the MEA region for more details.

Choosing the Right Sensor for the UAE Climate

When specifying motion detectors for lights in the UAE and the broader GCC region, environmental resilience is as important as detection capability. Standard sensors often fail prematurely due to intense heat, pervasive dust, and high humidity. For engineers and procurement teams, selecting devices robust enough to withstand these conditions is non-negotiable to avoid costly, frequent replacements.

This requires a detailed review of technical specifications beyond the headline features. A sensor installed in a Dubai warehouse or an Abu Dhabi car park must be engineered for reliability in harsh conditions.

The image below illustrates the primary sensor technologies, providing a visual comparison of the available options.

The progression from single-technology sensors to more advanced dual-technology units highlights the options available. For demanding environments where false triggers must be minimized, dual-technology models are the preferred choice.

Key Specifications for Regional Durability

When reviewing datasheets for a project in the UAE, several key specifications indicate a sensor's suitability for our climate.

-

IP (Ingress Protection) Rating: This is arguably the most critical factor. For outdoor applications or dusty indoor environments like workshops, parking garages, or industrial facilities, an IP65 rating is the absolute minimum. This certification ensures the unit is dust-tight and protected against low-pressure water jets, safeguarding internal components from corrosion and failure.

-

Operating Temperature Range: Many standard sensors begin to malfunction when ambient temperatures exceed 50°C. Specify detectors with a wide operating temperature range to ensure consistent performance inside a non-air-conditioned warehouse during a UAE summer.

-

UV-Resistant Housing: For any sensor exposed to direct sunlight, the housing must be constructed from a UV-stabilised material like polycarbonate. Without this, solar radiation will degrade the plastic over time, causing it to become brittle, crack, and compromise the IP rating.

Performance and Compliance Considerations

A durable sensor must also meet the project's performance requirements and comply with local regulations. Verifying certifications and performance metrics is essential for a smooth approval process.

For any project, ensuring your selected motion detectors for lights carry IEC (International Electrotechnical Commission) and relevant GCC conformity marks is essential. This not only guarantees a standard of quality and safety but also streamlines the approval process with local authorities and clients.

Key performance specifications to verify include:

-

Detection Range and Angle: The sensor's coverage pattern must match the space. A long corridor requires a different pattern (e.g., a 360-degree ceiling mount) than a wide, open-plan office (which may use a wide-angle wall mount).

-

Sensitivity Adjustment: The ability to fine-tune sensitivity is crucial for reducing false triggers. It allows installers to calibrate the sensor to ignore minor movements, such as a swaying tree branch visible through a window, and react only to human presence.

-

Time Delay and Lux Level Settings: An adjustable time delay prevents lights from switching off prematurely on a stationary occupant. Furthermore, a lux level setting maximises energy savings by keeping artificial lights off when sufficient natural daylight is available, making your energy management solution highly efficient.

Ensuring a product meets these criteria—from rugged construction to intelligent performance features—is how you can confidently specify motion detectors that deliver a reliable and effective energy management solution in Dubai and throughout the GCC.

Motion Detector Technology Comparison for GCC Applications

Selecting the correct sensor technology is critical in the GCC, where extreme environmental conditions can easily lead to false alarms or sensor failure. The following table compares the three primary types of motion sensors to help match the technology to your specific application and environment.

| Sensor Type | Detection Principle | Best Suited For | Key Advantages | Considerations in UAE Climate |

|---|---|---|---|---|

| PIR (Passive Infrared) | Detects changes in infrared radiation (body heat) from moving objects. | Offices, corridors, small rooms with clear lines of sight. | Cost-effective, low power consumption, excellent at detecting major motion. | Prone to false triggers from hot air drafts (AC units) or direct sun exposure on floors. |

| Microwave (MW) | Emits low-power microwaves and detects motion by analyzing the Doppler shift in the return signal. | Large open areas, spaces with obstacles (warehouses, car parks), and oddly shaped rooms. | Can detect motion through non-metallic objects (partitions, glass); highly sensitive to fine motion. | Can be too sensitive, potentially detecting movement outside the target area (e.g., through a thin wall). |

| Dual-Technology (PIR + MW) | Combines both PIR and Microwave sensors in one unit; both must trigger to activate the lights. | High-traffic areas, critical spaces where false triggers must be eliminated (classrooms, conference rooms). | Highest accuracy and reliability; virtually eliminates false alarms. | More expensive; complex setup requires careful calibration. |

By understanding these core differences, you can avoid common pitfalls. A simple PIR sensor might seem like a budget-friendly choice for a warehouse, but the constant false triggers from hot air movement will quickly become a nuisance. In that scenario, a more robust Microwave or Dual-Technology sensor is a far better long-term investment.

To discuss the specific needs of your project, you can explore the range of certified sensors in the GoSwitchgear online catalogue.

Installation and Placement Best Practices

A high-performance sensor is ineffective if installed incorrectly. For electricians and panel builders in the UAE, proper placement and wiring distinguish a reliable, energy-saving system from one plagued by issues. Correct installation of motion detectors for lights ensures maximum coverage, accurate detection, and the elimination of false triggers that undermine a project's objectives.

Proper installation from the outset saves significant time and cost during commissioning and reduces post-project callbacks. As industrial automation expands in the MENA region, these sensors are increasingly used for both lighting and safety applications. The safety motion control market is projected to grow at a CAGR of approximately 3% over the next five years, making installation expertise more valuable than ever. You can review market data on the MEA safety motion control market for a complete regional overview.

Strategic Sensor Positioning

Sensor placement is paramount. The primary objective is to cover major traffic areas—entry and exit points—so the sensor's detection cone blankets the paths people will take. Poor positioning results in blind spots and delayed light activation.

Adhere to these core placement principles:

- Mounting Height: Always follow the manufacturer's specifications. For ceiling-mounted sensors in a standard office, this is typically between 2.4 and 3.6 meters. Mounting too high or too low will compromise the sensor's effective range.

- Line of Sight: The sensor requires an unobstructed view of the monitored area. Obstacles such as storage racking, partition walls, or large machinery can create detection "shadows."

- Traffic Flow: Position the sensor so that occupants walk across its detection zones rather than directly toward it. PIR sensors, in particular, are more effective at detecting lateral movement.

Avoiding Common False Triggers in the GCC

The unique climate in the UAE and the wider GCC presents challenges that can lead to false alarms. Unwanted light activation is not just an annoyance; it wastes energy and erodes user confidence in the system.

The most common installation error is failing to account for the environment. A sensor aimed at an HVAC vent or exposed to direct afternoon sun is a guaranteed source of false triggers, especially if it is a basic PIR model.

To ensure reliable operation, follow these rules:

- Avoid Heat Sources: Never install a PIR sensor near an AC vent, heater, or equipment that emits significant heat. Sudden temperature changes can be misinterpreted as motion.

- Block Direct Sunlight: A sunbeam on the floor can create a warm spot that triggers a PIR sensor. Position units away from windows or select models with integrated light shields.

- Secure the Mounting: Ensure the sensor is firmly mounted. Vibrations from the building or nearby equipment can cause a loose sensor to trigger.

- Watch Out for Reflections: Be mindful when positioning microwave (MW) sensors. Aiming them at large metal surfaces or panes of glass can cause signal reflections and erratic triggering.

By carefully planning placement and considering these environmental factors, you will deliver a motion detection system that functions as a truly reliable and efficient energy management solution in Dubai.

Building a Complete Energy Management System

Motion detectors for lights are a crucial component, but their full potential is realised within a larger, integrated ecosystem. For project managers and system integrators in the UAE, the goal should be to move beyond standalone sensors and design a comprehensive energy management solution in Dubai. This involves layering technologies to maximise efficiency and deliver a greater return on investment.

A standalone sensor is reactive; an integrated system is proactive. It makes lighting controls more intelligent by providing them with more data points for decision-making.

Integrating Control Layers for Maximum Efficiency

The most advanced systems combine motion detection with other control inputs to create a layered logic where lights only activate when multiple conditions are met. This approach drastically reduces unnecessary energy consumption, especially in large-scale facilities like those in Jebel Ali.

Key technologies to integrate with your motion detectors for lights include:

- Daylight Sensors (Photocells): This is the most vital partner for a motion detector. A photocell measures ambient natural light and can inhibit the motion sensor from activating artificial lighting when sufficient daylight is present. This simple integration yields significant savings in buildings with extensive windows or skylights.

- Astronomical Time Clocks: These intelligent timers know the exact sunrise and sunset times based on the building's geographical location. They can be programmed to enable or disable motion sensors during specific hours—for instance, deactivating all outdoor security lighting during daylight hours to save energy and extend equipment life.

- Building Management Systems (BMS): For large commercial or industrial projects, integrating motion sensors into a central BMS is the ultimate solution. A BMS can orchestrate lighting across an entire facility, scheduling on/off times, dimming lights based on real-time occupancy data, and providing facility managers with detailed energy usage reports.

When integrated, a simple motion detector transforms from a basic switch into a valuable data-gathering node. Information on when and where motion is detected becomes powerful data for optimising building operations beyond just lighting.

Beyond Lighting Control: Space Utilization Analytics

The data from a network of motion detectors offers a powerful secondary benefit: space utilisation analytics. By tracking occupancy patterns over time, facility managers can gain deep insights into how different areas of a building are actually used.

This business intelligence can inform critical operational decisions:

- Optimizing Office Layouts: Identify underutilised desks or meeting rooms to reconfigure floor plans for improved collaboration and efficiency.

- Informing Cleaning Schedules: Focus janitorial resources on high-traffic zones and reduce cleaning frequency in areas that are rarely occupied.

- Improving HVAC Efficiency: Integrate occupancy data with the HVAC system to avoid conditioning empty sections of the building, leading to substantial energy savings.

Viewing motion detectors as the foundation of a complete system unlocks levels of efficiency and operational intelligence that a single sensor cannot provide. This strategic approach defines a modern, high-performance building in the GCC.

Partnering with GoSwitchgear for Your Lighting Control Needs

Specifying the right motion detectors for lights is a critical step toward creating a smart, secure, and energy-efficient facility. In the GCC climate, the key is to select high-quality, durable components. That is where GoSwitchgear provides value.

At GoSwitchgear, we are more than just suppliers; we are your strategic partners. Our team provides expert technical guidance and a deep inventory of durable, compliant solutions for projects across the UAE.

This focus is more critical than ever. The global motion detector market, valued at USD 7.5 billion in 2024, is projected to reach USD 17.2 billion by 2034. With smart city initiatives driving growth, the MEA region is a significant part of this expansion. You can learn more about motion detector market trends to see how quickly the local landscape is evolving.

Ready to implement intelligent lighting control in your facility? Reach our Dubai team for project consultations, technical support, and competitive quotes.

Frequently Asked Questions

When specifying and installing motion detectors for lights in the UAE, engineers and electricians face a unique set of challenges. From intense heat causing sensor malfunctions to questions about managing modern lighting loads, correct implementation is key to a reliable system.

Here are practical answers to the most common questions we encounter.

How Can I Prevent False Triggers in the UAEs Hot Climate

False activations caused by ambient heat are a significant problem for standard Passive Infrared (PIR) sensors in the GCC. A sensor can misinterpret a sun-heated wall as a person.

The most effective solution is to specify dual-technology (PIR+MW) sensors. These units require both a heat signature change (PIR) and physical movement detection (microwave) to occur simultaneously before activating the lights, dramatically reducing false alarms.

Additionally, adhere to these installation best practices:

- Never install sensors facing direct sunlight or windows.

- Keep them away from the direct airflow of HVAC vents.

- Adjust sensitivity settings during commissioning to fine-tune performance for the specific environment.

While these adjustments help, selecting a dual-technology sensor from the outset is the best strategy for high-temperature environments.

What Is the Best Sensor for a Large Warehouse

For large, high-ceiling spaces common in areas like Jebel Ali, the best options are Microwave (MW) sensors or specialised high-bay PIR sensors.

Standard PIR sensors have a limited effective range when mounted at height. Microwave sensors, however, fill the entire volume with a detection field and can sense motion through shelving. High-bay PIRs are engineered with special lenses designed for precise downward detection from high ceilings.

For the highest accuracy, especially in environments with automated machinery, a dual-technology high-bay sensor is the premier choice. It ensures lights are activated only by people or forklifts, not by other movements.

Can I Connect Multiple Motion Detectors to One Lighting Circuit

Yes, it is standard practice to wire multiple motion detectors in parallel to control a single lighting circuit. This configuration is ideal for long corridors, large open-plan offices, or irregularly shaped rooms.

When wired in parallel, any sensor that detects motion will activate the entire circuit of lights.

However, the critical consideration is the total lighting load. The combined wattage of all light fixtures must not exceed the rated capacity of a single sensor's relay. Always consult the manufacturer's datasheet for load limits and wiring diagrams to prevent overloading the relay. You can find these details from suppliers like GoSwitchgear.

Do I Need a Special Motion Detector for LED Lights

While most modern motion detectors for lights are compatible with LEDs, it is crucial to account for "inrush current."

LED fixtures draw a large, instantaneous spike of current upon activation, which is significantly higher than their normal operating current. This surge can damage a standard sensor's mechanical relay, leading to premature failure.

For commercial and industrial projects in Dubai, the best practice is to use detectors specifically rated for LED or electronic ballast loads. Look for a feature called "zero-crossing" switching. This technology protects the relay by timing the switch to coincide with the point where the AC voltage waveform is at zero. This "soft start" extends the life of both the sensor and the LED fixtures.

For robust, climate-ready motion detectors and expert support for your projects across the UAE, explore the full range of electrical components available from GoSwitchgear.

Leave a Reply