Optimising Control Panels in the GCC: A Guide to Selecting the Right Panel Cooling Fan

In the extreme climate of the UAE and the wider GCC, where high ambient temperatures, humidity, and pervasive dust are constant challenges, the reliability of electrical control panels is paramount. A high-performance panel cooling fan, or fan filter unit, is not merely an accessory; it is a critical component for ensuring operational continuity and protecting significant capital investments in sensitive electronics. This guide provides engineers, panel builders, and procurement teams with the essential knowledge to select, install, and maintain the optimal thermal management solution for their projects in Dubai, Abu Dhabi, and across the region.

Why a Panel Cooling Fan is Essential for UAE and Oman Projects

In regions like the UAE and Oman, ambient temperatures can regularly exceed 45°C. When combined with the internal heat load from components like VFDs, transformers, and an SMPS power supply, the temperature inside a sealed electrical enclosure can quickly surpass the safe operating limits of its contents. This thermal stress is a primary cause of premature component failure, nuisance tripping of breakers, and in worst-case scenarios, catastrophic system meltdowns leading to costly operational downtime.

The pervasive fine dust and high humidity in the Middle East introduce further risks. Without effective, filtered cooling, dust accumulates on components, acting as an insulator and trapping heat, while moisture can lead to corrosion and short circuits. A purpose-built panel cooling fan addresses these challenges by providing consistent forced air convection while preventing the ingress of contaminants. To understand the full scope of components at risk, a review of a comprehensive guide to electrical fittings and materials is beneficial.

The High Cost of Overheating

The financial impact of thermal failure extends far beyond the replacement cost of a single component. Consider the downstream consequences for key GCC industries:

- Manufacturing & Industrial: Unscheduled production halts can result in losses of thousands of dirhams per hour.

- Infrastructure & Utilities: Failure in critical control systems for power or water distribution can have widespread service impacts.

- Data Centres: Overheating can lead to irreversible data loss and service interruptions for an energy management solution Dubai.

- Reduced Component Lifespan: A fundamental rule of electronics states that for every 10°C increase above the recommended operating temperature, the operational lifespan of a component is effectively halved.

This is where robust, purpose-built solutions like Italian-engineered Fandis fan filter units become non-negotiable. They are specifically designed to deliver reliable cooling performance while providing superior protection against environmental contaminants. Proper selection and maintenance, validated through a routine electrical panel inspection, are crucial for ensuring your critical infrastructure remains operational and reliable in the demanding GCC climate.

Decoding Panel Cooling Fan Specifications for the GCC Market

Selecting the correct panel cooling fan requires a technical understanding of key performance characteristics. For engineers and panel builders in the UAE, Oman, and KSA, focusing on the right specifications ensures both effective thermal management and long-term durability against local environmental challenges. A deep dive into the nuances, like understanding DC vs AC fan considerations, is vital for system integration and performance.

Essential Fan Characteristics for Control Panel Fans

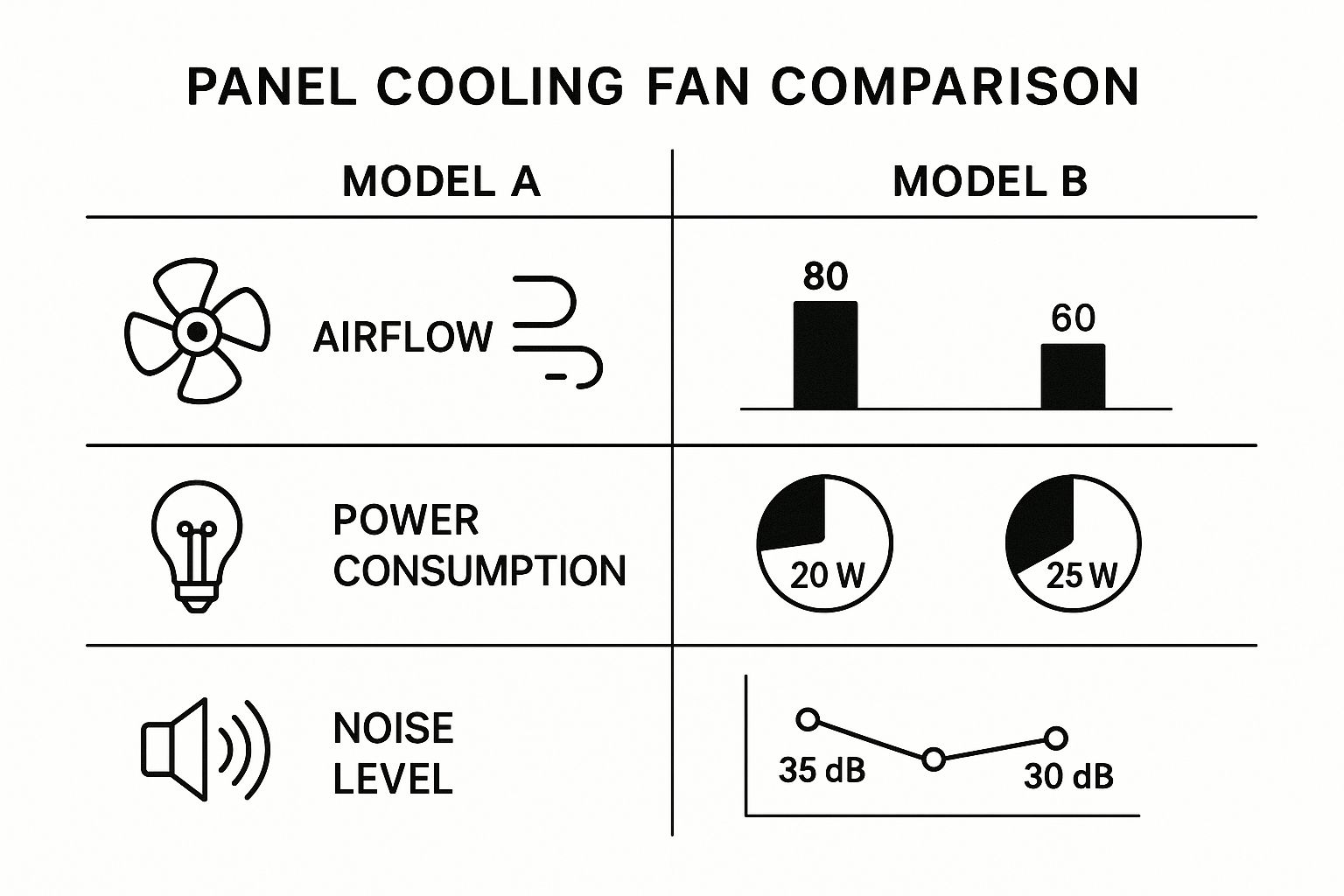

Three specifications are critical when designing a reliable cooling system for a GCC application: Airflow Rate, Fan Rotation, and the IP (Ingress Protection) Rating.

- Fan Speed & Airflow Rate (m³/h): This metric defines the volume of air the fan can move per hour. Calculating the required airflow based on the panel’s internal heat load (in Watts) and the desired temperature differential (ΔT) is the first step in proper fan selection. Higher airflow is essential for larger panels or enclosures with a high density of heat-generating components.

- Fan Rotation (Forward vs. Reverse): The direction of airflow is critical for contamination control.

- Forward Rotation (Pressurisation): The fan pushes filtered air into the enclosure, creating positive internal pressure. This is the recommended method for the dusty environments of the UAE and Middle East, as it forces air out through any unsealed gaps, effectively preventing dust and debris from entering.

- Reverse Rotation (Depressurisation): The fan extracts hot air from the enclosure, creating negative pressure. This can draw unfiltered air and contaminants in through panel gaps, increasing the risk of component failure.

- IP Rating (Ingress Protection): This IEC 60529 standard is a crucial indicator of a fan’s resilience. The two digits represent protection against solids (first digit) and liquids (second digit).

Why IP54 is The Benchmark For The Middle East

For industrial applications across the UAE and the wider GCC, an IP54 rating is the recommended minimum. This certifies that the unit is protected against dust ingress (Level 5) and water splashes from any direction (Level 4). This level of protection is vital for safeguarding sensitive electronics from the region’s fine dust and occasional moisture. In environments with high humidity or exposure to wash-downs, upgrading to an IP55-rated unit provides enhanced protection against water jets.

At GoSwitchgear, we supply Italian-made Fandis fan filter units precisely because they are engineered to meet these demanding standards. Renowned for their robust construction, Fandis is a trusted brand for projects where reliability is non-negotiable, ensuring valuable electrical components UAE are kept cool and clean.

The Critical Role of Filters in Panel Protection

Operating a panel cooling fan without an appropriate filter in the industrial landscapes of the UAE is akin to leaving a window open in a sandstorm. The fan circulates air, but it also pulls in abrasive dust and particulates that can cause catastrophic failures in sensitive electronics. The filter is the critical barrier that ensures only clean, cool air reaches your components.

The need for effective filtration is underscored by market trends. The Middle East & Africa have seen a dramatic increase in cooling fan installations, with a significant portion deployed in the UAE and Saudi Arabia for critical infrastructure. This growth, detailed in this full market growth analysis, highlights the non-negotiable requirement for clean, reliable cooling solutions.

Understanding Filter Class and Materials

The effectiveness of a filter is defined by its class, typically rated from G2 to G4 based on EN 779 standards. Matching the filter class to the operating environment is essential for asset protection.

- Filter Class G2: Provides coarse filtration, suitable for environments with low levels of airborne particulates.

- Filter Class G3: A common choice for general industrial applications, offering effective filtration of common dust particles.

- Filter Class G4: The standard for dusty and demanding environments. G4 filters provide a fine barrier against the pervasive dust found across many GCC industrial sites, making them the optimal choice for protecting high-value electrical components in the UAE.

The filter media itself is also important. Quality filters, such as those from Fandis, use washable synthetic fibres. This offers a significant operational advantage, as the filters can be cleaned and reused, reducing long-term maintenance costs and environmental waste.

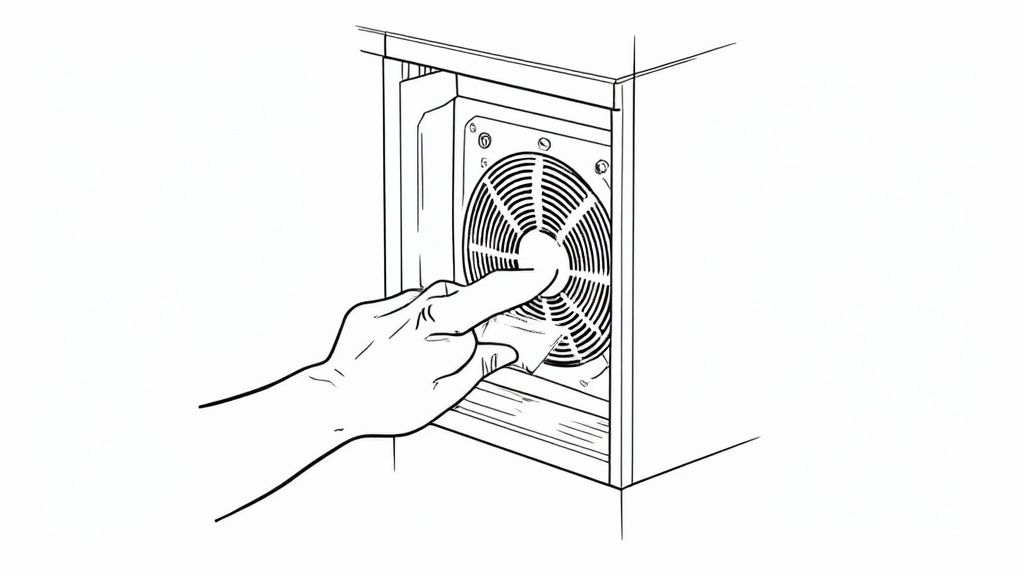

Maintenance Best Practice: A clogged filter severely restricts airflow, forcing the fan to work harder and leading to a rise in internal temperature—defeating the purpose of the cooling system. A proactive maintenance schedule is essential. For most industrial sites in the GCC, monthly filter inspection is recommended. If dirty, the filter can be easily removed, washed, dried, and reinstalled. This simple task is one of the most cost-effective measures to ensure optimal performance of your panel cooling fan.

Building a Complete Panel Climate Control System

A high-performance panel cooling fan is the core of an enclosure’s thermal management, but for maximum efficiency and protection in the demanding climates of the UAE and Oman, it should be integrated into a complete, automated climate control system. This intelligent approach conserves energy and significantly extends the service life of every component within the electrical panel board.

Operating a fan continuously is inefficient. A smarter strategy involves a responsive system that adapts to real-time conditions inside the enclosure, ensuring cooling is only activated when necessary.

Intelligent Control: Thermostats and Hygrostats

Thermostats and hygrostats are the brains of an automated climate control system, providing intelligent command over fans and heaters. They are essential for creating an efficient energy meter GCC-compliant system.

- Thermostats: A thermostat monitors the internal enclosure temperature. It activates the panel cooling fan only when a preset temperature threshold is exceeded and deactivates it once a safe temperature is restored. This prevents unnecessary fan operation, reducing energy consumption and mechanical wear.

- Hygrostats: In the humid coastal areas of the GCC, a hygrostat is crucial. It measures relative humidity and activates the fan to circulate air if moisture levels approach the dew point, preventing condensation that can cause corrosion and short circuits.

The Synergy of Heaters and Fans for Total Climate Stability

While it may seem counterintuitive, pairing a panel heater with a cooling fan provides the ultimate environmental control. During cooler nights or in heavily air-conditioned facilities, a small anti-condensation heater, controlled by a hygrostat or thermostat, prevents the internal temperature from dropping to the dew point.

By gently warming the internal air, the heater lowers the relative humidity, preventing moisture from condensing on critical electrical components in UAE. When the temperature rises, the thermostat switches off the heater and engages the cooling fan. This synergistic system, combining a fan, filter, thermostat, hygrostat, and heater, creates a stable internal microclimate, protecting valuable assets from both extreme heat and damaging moisture. Fandis provides a complete range of these components, engineered to work in harmony for mission-critical reliability.

How to Select the Right Fandis Fan Model

Selecting the correct Italian-made Fandis fan model from GoSwitchgear is a critical decision for ensuring system reliability for projects across the UAE and Oman. The process is straightforward and involves matching fan specifications to the enclosure’s thermal and environmental requirements.

Fandis also addresses aesthetic integration by offering their fan filter units in two standard industry colours: RAL 7035 (Light Grey) and RAL 7032 (Pebble Grey). These colours match the majority of electrical enclosures, ensuring a professional and seamless finish for any panel build.

Matching Specs to Your Application

The selection of the right panel cooling fan is determined by three key factors: available voltage, enclosure size, and the calculated heat load.

- Fan Speed and Airflow (m³/h): This is the most critical performance metric. A higher airflow rate is required for larger panels or those with a high concentration of heat-generating equipment like VFDs or an SMPS power supply. Fandis offers a wide range of models to meet any airflow requirement.

- Rotation Direction: For the dusty environments of the UAE and GCC, forward rotation is essential. By pressurising the cabinet, it creates an effective barrier against dust and contaminants.

- IP Rating: IP54 is the benchmark for most industrial applications in the region, offering robust protection against dust and moisture. This should be considered a non-negotiable feature for protecting sensitive electronics.

The Value of an Integrated Solution

The demand for effective cooling is growing across the Middle East, driven by large-scale infrastructure projects aligned with national strategies like Saudi Vision 2030. This is fueling the need for energy-efficient technologies, including the panel cooling fan.

Expert Tip: For an intelligent and efficient energy management solution Dubai, always pair your Fandis fan with a thermostat. This simple addition ensures the fan operates only when needed, delivering significant energy savings and extending the fan’s operational life. For more advanced control schemes, an understanding of the application of solid state relays can be highly beneficial. For tailored advice on selecting the right Fandis fan and climate control components for your project in Dubai, Abu Dhabi, or anywhere in the GCC, contact the experts at GoSwitchgear today.

Which Colour Should I Choose for My Fan?

While functional performance is paramount, aesthetics contribute to a professional installation. Fandis fan filter units are available in the two most common colours for industrial enclosures:

- RAL 7035 (Light Grey)

- RAL 7032 (Pebble Grey)

Selecting the colour that matches your cabinet ensures a clean, integrated appearance, reflecting the quality of the build. Good quality Fandis filters are made with washable synthetic media, making maintenance quick and easy. This proactive cleaning is vital for protecting your panel cooling fan and the valuable electrical components in UAE it guards.

Leave a Reply