Mastering PID Temperature Controllers for UAE & GCC Industries

In the high-stakes industrial world of the UAE and GCC, where every degree, liter, or pound per square inch counts, precision isn’t just a goal—it’s the backbone of the entire operation. This is where PID temperature controllers come in. In process control, they are the intelligent heart of any modern system, working tirelessly to automatically fine-tune outputs and ensure everything from temperature to flow stays exactly where you need it, preventing costly mistakes and waste.

What is a PID Temperature Controller and Why is it Essential?

Across the demanding industrial sectors of the UAE and the wider GCC, stability is everything. It’s not just a nice-to-have metric; it’s fundamental to profitability. Whether you’re in manufacturing, water treatment, or designing HVAC systems to battle the region’s heat and humidity, how well you regulate variables like temperature has a direct line to your product quality, safety, and energy bills. This is where a PID controller, a vital electrical component in the UAE, truly shines.

A simple on/off thermostat is too clumsy for professional applications, leading to wide temperature swings that are unacceptable for sensitive industrial processes. A PID temperature controller plays a much smarter game.

Think of It Like Cruise Control for Your Industrial Process

Imagine you’re driving a car with a really good cruise control system. You set the speed to 100 km/h, and the system takes over. It’s not just mindlessly turning the engine on and off.

- When you start going up a hill (a disturbance), it smoothly gives the engine more gas to stop you from slowing down.

- As you head downhill, it eases back on the throttle so you don’t speed up.

- It’s constantly making tiny, smart adjustments to keep you locked at that 100 km/h mark, no matter the road conditions.

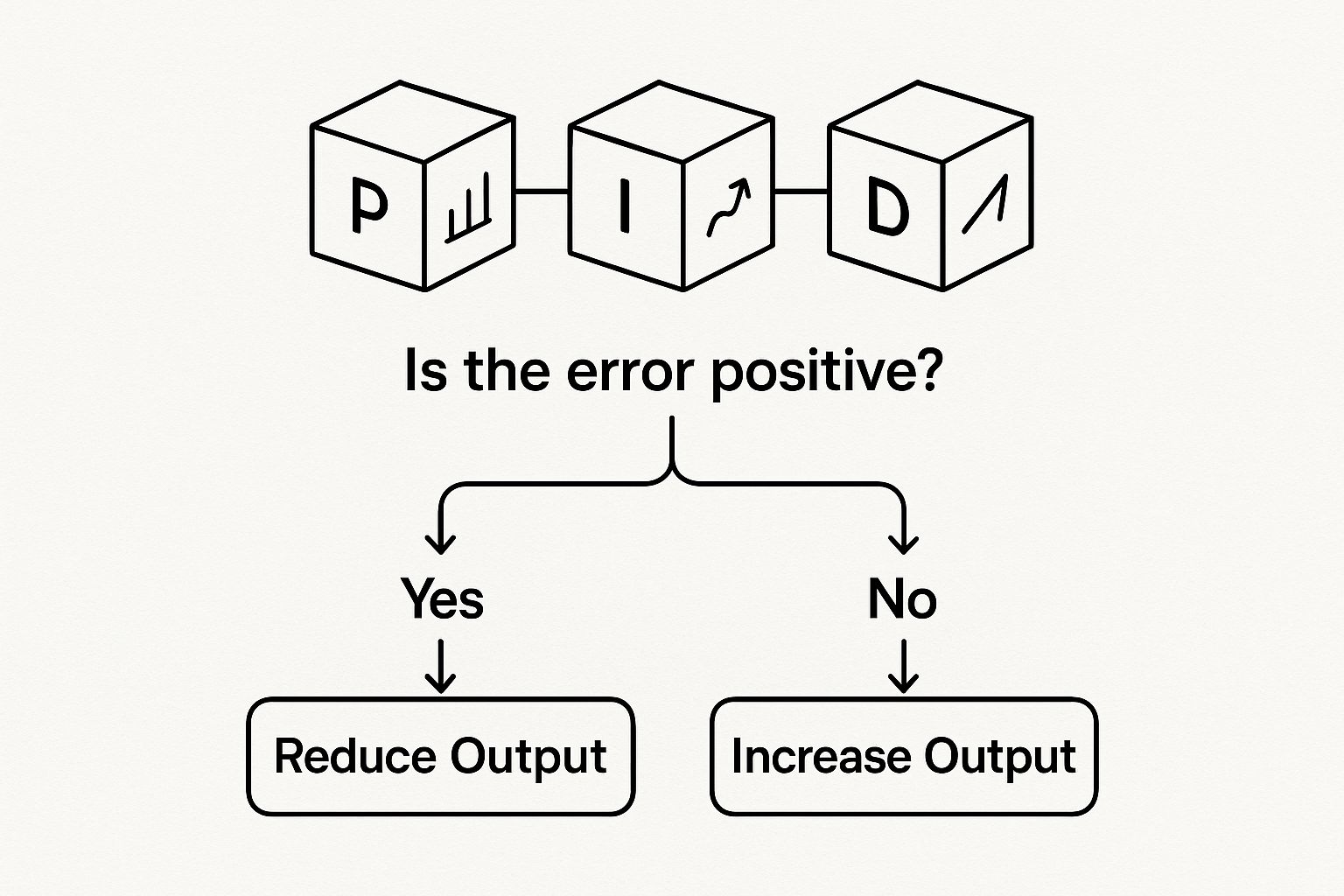

That’s exactly how a PID (Proportional-Integral-Derivative) controller works. It constantly looks at the difference (the “error”) between where you want to be (the setpoint) and where you actually are (the process variable). Then, using three distinct but coordinated actions, it calculates the perfect response. To dig even deeper, check out our comprehensive guide on PID controllers.

Key Takeaway: A PID controller isn’t a basic on/off switch. It’s a dynamic, intelligent device using a three-part algorithm (Proportional, Integral, Derivative) to keep a process incredibly stable. It’s like having an expert driver with their foot on the gas, constantly adapting to keep the ride smooth.

The Three Pillars of PID Control

The real magic of these controllers comes from how their three terms work together to tackle the past, present, and future of any process error.

- Proportional (P) Action: This is the immediate, gut reaction. It looks at the current error and applies a corrective force that’s proportional to the size of the problem. Big error, big response.

- Integral (I) Action: This term has a long memory. It looks at the past by adding up all the previous errors over time. This is critical for wiping out small, stubborn “steady-state” errors that the Proportional term might ignore, bringing your process perfectly back to the setpoint.

- Derivative (D) Action: This is the forward-looking, predictive part. It analyzes how fast the error is changing. By anticipating where the error is headed, it can dampen the controller’s response, preventing it from overshooting the target and causing oscillations. The result is a much smoother, more stable process.

For panel builders and engineers in Dubai, Abu Dhabi, and across the region, understanding this logic is essential for building control panels that are resilient and remarkably efficient, especially in facilities dealing with local climate challenges like heat and dust.

How to Select the Right PID Temperature Controller

Choosing the right PID controller is a critical decision for system integrators and procurement teams in the UAE and across the energy meter GCC region. The wrong choice can lead to poor control, costly operational headaches, and project delays. Picking the right controller prevents over-specifying (and over-paying) or under-specifying (and dealing with constant performance issues).

By walking through your specific needs, you can confidently select the perfect device for the job.

The image above breaks down how the Proportional (P), Integral (I), and Derivative (D) elements work together. It’s a constant balancing act—reacting to the present error, correcting for past mistakes, and anticipating future changes—to keep your process perfectly stable.

Step 1: Match the Input Sensor Type

First, your controller must be compatible with your sensor. This is the most fundamental step. PID controllers are built to accept specific signal types from sensors.

- Thermocouples (J, K, R, S types): These are the workhorses of temperature sensing. If your process relies on a K-type thermocouple, you need a controller with a dedicated K-type input.

- RTDs (like Pt100): When precision is critical, you’ll likely use an RTD (Resistance Temperature Detector). They offer superior accuracy. Ensure the controller supports your specific RTD model, like the common Pt100.

- Analogue Signals (4-20mA or 0-10V): For variables like pressure, humidity, or flow, the sensor or transmitter usually sends out a standard analogue signal. Your controller must have the corresponding 4-20mA or 0-10V input.

In the challenging climates of the UAE and KSA, extreme heat and dust can impact sensor readings. It’s crucial to pair a high-quality, properly calibrated sensor with a controller that has a high IP rating and robust input circuitry to ensure data reliability.

Step 2: Choose the Right Output Type (Relay vs. SSR)

The controller’s output tells your final control element—like a heater, contactor, or valve—what to do. The two most common output types for temperature control are Relay and SSR Drive.

| Output Type | Best For | Switching Speed | Lifespan | Typical Application (GCC Context) |

| :— | :— | :— | :— |

| Relay | High-power, infrequent switching loads | Slow | Mechanical (Limited Cycles) | Large-capacity water tank heaters or industrial ovens where on/off cycles are infrequent. |

| SSR Drive | Fast, frequent switching; precise control | Very Fast | Solid-State (Very Long) | Plastic injection molding, packaging machinery, and any process needing rapid heat-cool cycles. A solid-state relay (SSR) is the superior choice here. |

Using a mechanical relay for a fast-cycling process is a recipe for premature failure and costly downtime. An SSR output is the far more reliable and cost-effective choice for such applications.

Step 3: Determine the Number of Relays Needed

Many PID temperature controllers offer auxiliary relays in addition to the primary output. These are incredibly useful for adding automation, alarms, and safety interlocks to your system.

Here’s how they are typically used:

- High/Low Alarms: To trigger a beacon or siren if the process temperature goes dangerously high or low, a critical safety feature in high-temperature industrial environments.

- Band Alarms: To activate an alarm only when the process value drifts outside a predefined “safe” operating window.

- Multi-Stage Control: In heavy-duty heating applications, a second relay can activate an auxiliary heater if the primary one cannot meet demand.

For a great example of a flexible controller with multiple relay options, check out the Multispan UTC-421P PID controller available through GoSwitchgear.

Step 4: Plan for System Integration with MODBUS RS-485

Modern facilities in Dubai and Abu Dhabi demand an energy management solution Dubai that allows centralized control and monitoring. This is where communication protocols are essential. The industry standard for this is MODBUS RS-485.

When your controller has MODBUS capability, you can connect it to a central HMI, PLC, or SCADA system. This unlocks:

- Reading live process values from a central control room.

- Changing setpoints remotely without physically touching the controller.

- Monitoring all alarm statuses in real-time.

- Logging process data for quality control reports and compliance with local utility regulations.

For any project involving smart facility management, choosing controllers with MODBUS RS-485 is a future-proof investment.

The Art of PID Tuning for Peak Performance

An untuned PID controller is like a world-class race car with the wrong tires—all potential, zero performance. For the process stability and energy efficiency demanded by industries across the UAE, proper tuning is non-negotiable. With the fluctuating operational demands common in the Middle East, a well-tuned controller is your first line of defense against waste and equipment strain.

The goal of tuning is to find the perfect balance between the Proportional (P), Integral (I), and Derivative (D) values. This dictates how your controller behaves—whether it needs a lightning-fast response or must avoid overshooting the setpoint.

This need for precision helps explain the rapid adoption of automation across the region. The Middle East, especially the UAE and Saudi Arabia, has seen a huge surge in PID controllers adoption. You can explore detailed insights on the regional PID controller market to learn more.

Demystifying the Auto-Tune Function

Many modern PID controllers come with a game-changing feature: Auto-Tune. This function automates the tuning process, saving a massive amount of time during system commissioning.

When activated, the controller deliberately “excites” the system by cycling the output. It observes how the process reacts—how fast it rises, how much it overshoots, and how it settles. Based on these observations, its internal algorithm calculates and sets optimal P, I, and D parameters automatically.

Practical Tip: Auto-Tune is a lifesaver for most standard applications. For best results, always run the Auto-Tune function when your process is at or near its normal operating setpoint to ensure it learns the system’s behavior under typical conditions.

A perfectly tuned control loop is a direct contributor to your bottom line. It protects equipment, slashes energy consumption by eliminating wasteful oscillations, and guarantees consistent product quality.

Unlocking Advanced Control with MODBUS RS-485

Today, PID controllers are key players in the connected, automated environments driving Industry 4.0 across the GCC. For system integrators and panel builders, understanding communication protocols is crucial.

MODBUS RS-485 acts as the central nervous system for your control panel. It’s a robust serial communication standard that lets you link multiple controllers to a central brain like a PLC, HMI, or SCADA system.

The Tangible Benefits of a Connected System

Integrating PID controllers with MODBUS brings real, practical advantages for facilities in Dubai and Abu Dhabi.

- Simplified Data Logging: Automatically pull process data for compliance reports and quality analysis.

- Remote Adjustments & Monitoring: Change setpoints or check alarms from the central control room, saving technician time.

- Predictive Maintenance Alerts: A central system can spot trends, signaling potential equipment failure before it causes a costly shutdown.

This shift toward smarter systems is driving market growth. The global PID controller industry is expected to climb to USD 2.24 billion by 2032, with significant investment from the UAE, Saudi Arabia, and Qatar in sectors where integrated control is a must.

Advanced Features for Complex Processes

Many modern PID controllers with MODBUS offer advanced programming functions perfect for specialized applications.

Key Insight: Choosing a controller with features like ramp/soak profiling and soft-start functions future-proofs your control panel. It means you can take on more complex jobs without requiring a complete overhaul.

Ramp and Soak Profiling

Processes like heat-treating metals require precise thermal cycles. Ramp/soak profiling lets you program a multi-stage temperature journey:

- Ramp: Gently increase the temperature at a set rate.

- Soak: Hold the temperature steady at a specific point for a set time.

- Repeat: The controller can automatically run through a sequence of ramp and soak steps.

This programmability guarantees consistent, high-quality results in tricky thermal processes.

Soft-Start Function

The soft-start function gradually applies power to a heavy load, like a large industrial heating element. This prevents massive initial current surges that can trip breakers or stress components, extending the life of your equipment.

For a controller that packs these advanced features, consider the GoSwitchgear PTC-4202A-M1 with MODBUS RS-485.

Your Partner in GCC Process Control

Getting PID control right is essential for achieving precision, efficiency, and safety in the GCC’s demanding industrial sectors. Every step—from picking the right inputs to the art of tuning—plays a huge role in operational excellence.

The market backs this up. With industrial diversification and smart energy initiatives, the regional PID controller market is expected to hit nearly USD 1.86 billion by 2033. You can dig into the numbers in this full market analysis on PID controller growth in the Middle East.

This growth highlights the importance of a technical partner who understands the unique challenges of operating in this region. That’s where GoSwitchgear comes in. We’re not just a supplier; we are an extension of your engineering team.

Our Commitment: We provide engineers, panel builders, and procurement managers in the UAE with more than just top-tier components like a SMPS power supply or DIN rail isolator. We deliver the practical know-how you need to make your projects a success.

If you need expert advice on selecting and implementing the right PID temperature controllers for your projects—whether in Dubai, Abu Dhabi, or anywhere in the GCC—our team is ready to provide project support.

Frequently Asked Questions

Here are some of the most common questions our engineers encounter when working with PID controllers on projects in the UAE.

What’s the Real Difference Between a Thermostat and a PID Controller?

A thermostat is a simple on/off switch. This crude control creates noticeable temperature swings, overshooting and undershooting your target. A PID controller is like a dimmer switch with a brain. It uses a sophisticated algorithm (Proportional, Integral, and Derivative logic) to intelligently feather the output, delivering just the right amount of energy to hold a setpoint with incredible stability. In the demanding industrial environments across the UAE, that precision prevents product waste and reduces energy costs.

When Should I Use an SSR Output Instead of a Relay?

The choice between a Solid State Relay (SSR) and a mechanical relay comes down to switching speed.

Choose an SSR output when your process needs rapid cycling, like in packaging or plastics machinery. SSRs have no moving parts, offering a much longer, silent operational life. Go with a standard Relay output for slower, heavy-duty jobs like large tank heating where switching is infrequent. Relays are tough, cost-effective workhorses for demanding industrial sites across the GCC.

Why Is MODBUS RS-485 So Important for Smart Buildings in Dubai?

In a nutshell, MODBUS RS-485 is the communication backbone for an intelligent system. It lets you network multiple PID controllers and other devices, linking them back to a central Building Management System (BMS). This is critical for the advanced smart facilities in Dubai, allowing facility managers to monitor energy use, adjust setpoints remotely, and consolidate alarms from a single screen, boosting operational efficiency.

Can One PID Controller Manage Both Heating and Cooling?

Yes, many modern PID controllers are designed with dual outputs for “heat/cool” applications. One output drives a heating element, while the second controls a cooling system (like a fan or chilled water valve). The controller’s logic coordinates both actions, preventing them from fighting each other. This is perfect for environmental test chambers or complex chemical processes common in the UAE that require a stable temperature year-round.

At GoSwitchgear, we don’t just sell components; we provide the expertise to help you build reliable, high-performance control systems designed for the GCC market. Explore our extensive range of PID controllers and process control solutions today.

Leave a Reply