Mastering Residential Electrical Panel Wiring for Modern UAE & GCC Projects

The electrical demands on a modern villa in the UAE are staggering, pushing older systems well beyond their limits. For engineers and electricians, residential electrical panel wiring is about building the electrical heart of a home—one that must reliably power high-capacity air conditioning, smart home ecosystems, and future upgrades like EV chargers, all within the demanding GCC climate.

Matching the Panel to Modern UAE Home Demands

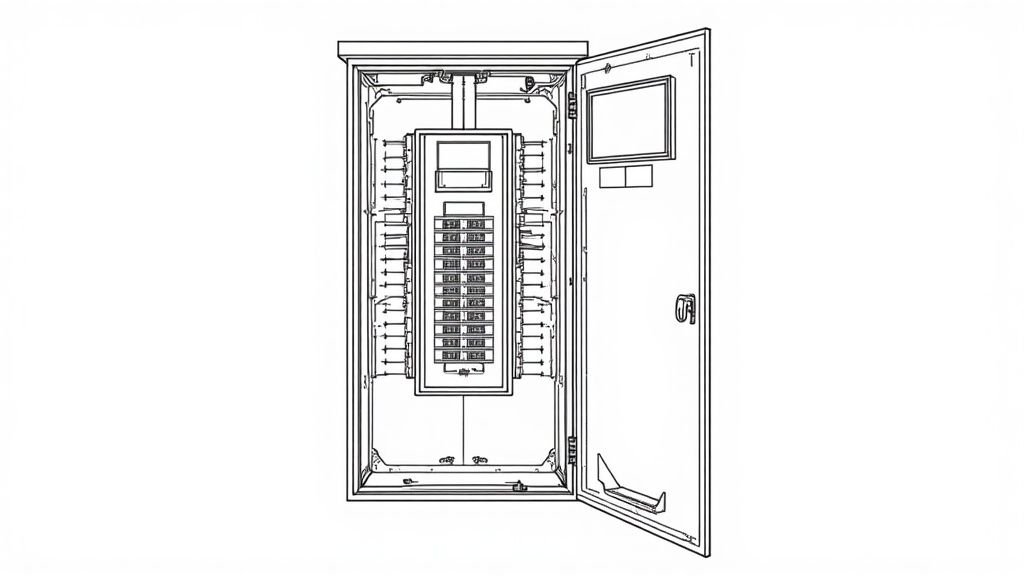

The standard for residential electrical panels has evolved dramatically in the fast-paced GCC construction sector. A panel is no longer just a box of breakers; it is the core of a home's safety and future-readiness. The first, most crucial step is to accurately assess the property's real-world electrical needs, considering the unique environmental challenges of the region.

Assessing Real-World Power Consumption

In the UAE, the single largest load in any residence is air conditioning. During peak summer months, multiple high-capacity AC units create an immense, sustained strain on the electrical system. This must be the primary consideration in any load calculation.

Beyond cooling, the combined load includes:

- Smart Home Systems: Integrated lighting, automated blinds, security cameras, and network servers create a constant power demand.

- High-End Kitchens: Homes in Dubai and Abu Dhabi often feature multiple ovens and powerful induction hobs, each requiring dedicated, high-amperage circuits.

- Future-Proofing: An EV charging station, a pool heater, or an external majlis can easily overwhelm a panel sized only for today's needs.

A 100A panel, once standard, is now insufficient. New residential projects across the UAE often require panels rated at 200A or more. This is a necessary step to handle modern electrification demands and ensure long-term reliability. GoSwitchgear offers a comprehensive range of electrical components for the UAE market to meet these specifications.

Pro Tip: A common engineering mistake is sizing a panel with no buffer. Always design for a 20-25% buffer capacity. This accommodates future technologies and prevents costly panel upgrades, a key selling point for clients.

From Component Box to System Core

Viewing the panel as the central hub of the electrical system is critical. It’s not just about having enough slots; it's about ensuring busbar ratings, main breaker capacity, and the panel's IP rating can safely handle the full potential load under the harsh heat and humidity of the GCC climate. A well-planned panel, using quality electrical components in the UAE, ensures balanced loads, eliminates nuisance tripping, and creates a safe, serviceable system compliant with local utility regulations.

A thorough site evaluation is non-negotiable. For a detailed checklist, review our guide on professional electrical panel inspection, ensuring your project starts on a compliant foundation.

Before touching a wire, the preparatory work defines a professional installation. This is about a rigorous process to ensure the panel is completely de-energized and safe.

https://www.youtube.com/embed/Xo_xUJvj9jQ

Always confirm the panel has no power. After killing the main breaker, use a quality multimeter to test all incoming service lugs and busbars. Never assume a panel is dead. This mandatory step prevents serious, life-threatening injury.

For further reference, it's wise to review essential safety tips for electrical service to maintain safety on site.

Essential Gear and Strategic Layout

Your personal protective equipment (PPE) is non-negotiable. Essential gear includes:

- Insulated Gloves: Rated for the correct voltage.

- Safety Glasses: For protection against debris and arc flash.

- Proper Footwear: Non-conductive, safety-toed boots are standard.

Equally critical is mapping out the circuit layout before pulling wires. Draft a detailed panel schedule listing every circuit, its purpose (e.g., kitchen outlets, AC unit), and its corresponding breaker. A well-designed schedule ensures the load is balanced across the panel's phases, preventing breaker trips and panel overheating—a significant risk in the GCC’s high ambient temperatures.

A balanced panel improves performance and simplifies future troubleshooting. Another engineer or electrician should be able to understand the system instantly from your panel schedule.

This planning stage is also where you ensure compliance with local codes. For example, regulations specify at least 1 meter (~3 feet) of clear working space in front of the panel, with the door opening a full 90 degrees. This level of planning guarantees a safe, logical, and compliant installation.

Executing a Clean and Compliant Panel Installation

With preparation complete, the focus shifts to wiring the panel. This stage requires meticulous work to ensure a professional, safe, and long-lasting installation, especially given the demanding climate in the UAE. Clean connections, smart wire routing, and adherence to specifications are paramount.

The heavy-gauge service entrance conductors must be landed on the main breaker with precision. A calibrated torque wrench is mandatory. Every main breaker has specific torque values listed in its technical documents. Adhering to these values ensures a solid, low-resistance connection that will not overheat under the heavy load of AC units.

Branch Circuit Wiring Best Practices

Once the main breaker is secure, the focus turns to individual branch circuits. The goal is a panel that is not just functional but also easily serviceable.

Start by stripping wires cleanly without nicking the copper. Route each wire neatly along the enclosure's sides, following a clear path to its assigned circuit breaker. This organized approach to residential electrical panel wiring improves airflow, helping manage heat and extending component life—a crucial benefit in hot climates.

Key best practices include:

- Leave a Service Loop: A small amount of extra wire provides slack for future re-termination without pulling a new wire.

- Secure Neutrals and Grounds: Land neutrals and grounds on their correct bus bars. Crucially, each neutral wire requires its own dedicated terminal screw. Doubling up is a code violation and a serious safety hazard.

- Logical Breaker Placement: Follow your panel schedule to install breakers in a sensible order. Grouping related circuits makes the panel intuitive for future maintenance. Procure reliable components for your electrical panel board from trusted suppliers like GoSwitchgear to ensure quality and compliance.

For a quick reference on pairing wires with breakers for common residential applications in the region, consult this table.

Recommended Wire Gauge and Breaker Ratings for UAE/GCC Circuits

This table provides a reference for matching copper wire size (mm²) to the appropriate circuit breaker for typical residential applications in the UAE and KSA, ensuring safety and compliance with IEC and local standards.

| Circuit Application | Typical Amperage (A) | Recommended Copper Wire Gauge (mm²) | Notes & Considerations |

|---|---|---|---|

| Lighting Circuits | 10A – 15A | 1.5 mm² – 2.5 mm² | LED loads are lower but plan for future changes. |

| Standard Wall Outlets (Sockets) | 15A – 20A | 2.5 mm² – 4.0 mm² | Use 4.0mm² for high-use areas. |

| Kitchen & Utility Outlets | 20A | 4.0 mm² | Often requires dedicated circuits per appliance. |

| Small AC Units (Window/Split) | 20A – 30A | 4.0 mm² – 6.0 mm² | Verify manufacturer specs for exact requirements. |

| Electric Water Heaters | 20A – 30A | 4.0 mm² – 6.0 mm² | Must be on a dedicated circuit. |

| Central AC / Large Appliances | 40A+ | 10.0 mm² or larger | Requires specific load calculation. |

Using the correct combination is fundamental to preventing overloads and potential fire hazards. Always verify against the latest local utility regulations (e.g., DEWA, SEC).

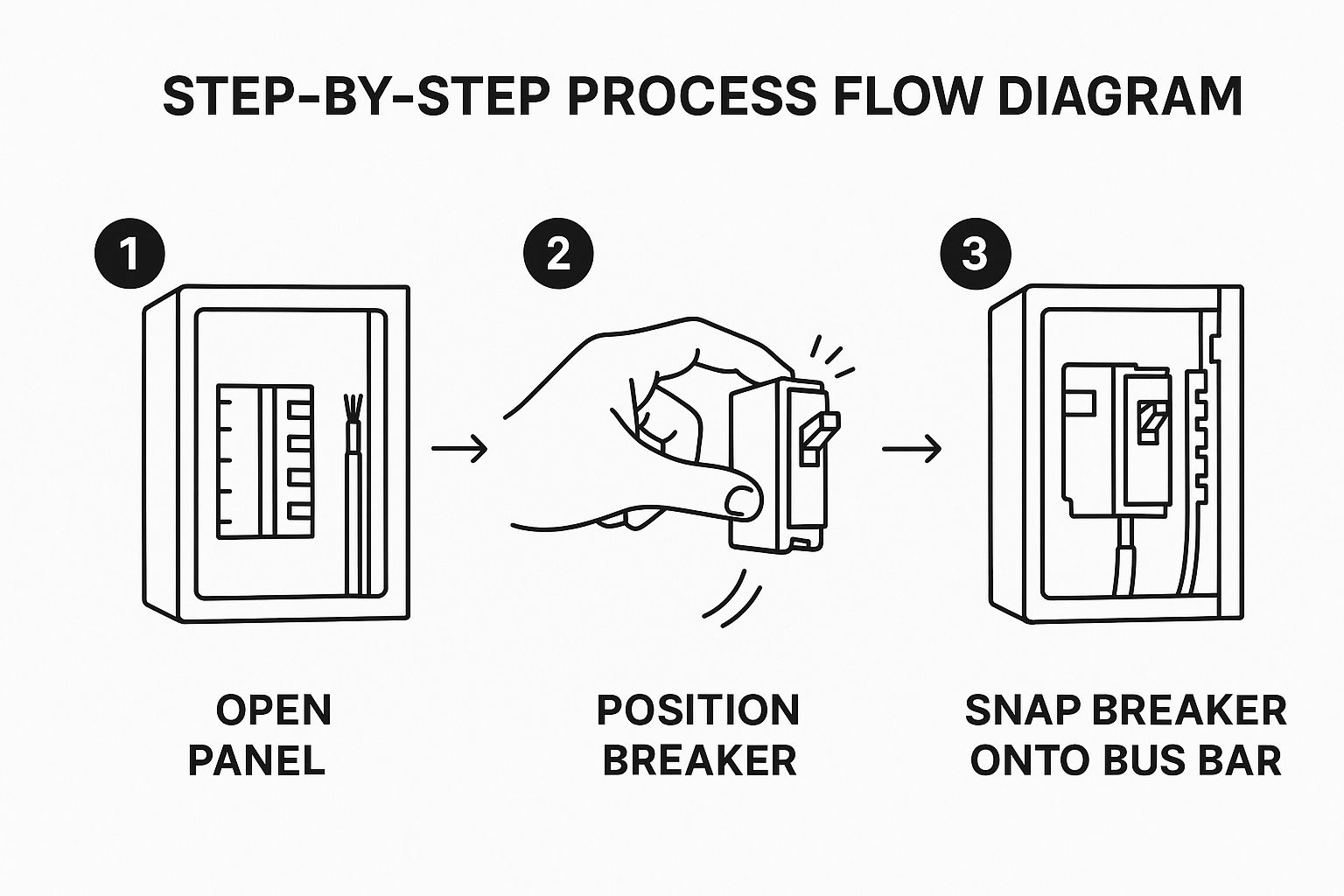

The image below shows the critical step of ensuring a breaker is seated correctly.

The breaker must be snapped firmly onto the bus bar, creating a secure electrical and mechanical connection—the foundation of a reliable circuit.

A clean, organized panel is the signature of a professional installer. It communicates that the work was done with precision and a deep understanding of electrical safety principles.

Finishing the Job with Professional Wire Management

The finish work distinguishes a professional installation. A neatly organized panel reflects a commitment to safety and longevity. The final steps of a residential electrical panel wiring project are crucial for a high-quality, professional outcome.

Effective wire management is critical, especially given the high ambient temperatures across the GCC. Tangled or tightly bundled wires cannot dissipate heat properly, restricting airflow and increasing operating temperatures, which can shorten the life of circuit breakers. Using wire ties to create clean runs along the enclosure sides prevents this.

Creating a Clear and Permanent Panel Schedule

The panel schedule is the roadmap to the home's electrical system and a critical finishing touch. A poorly executed schedule is a disservice to the property owner and any future maintenance personnel.

To create a professional schedule:

- Use a permanent marker or a label maker. Pencil fades in dusty or humid environments common in the GCC.

- Be specific. "Outlets" is insufficient. "Living Room Outlets – South Wall" is professional. Specify "Master Bedroom AC Unit," not just "AC."

- Ensure legibility. The next person opening the panel must understand the system at a glance.

A typical UAE home may have 20 to 30 circuit breakers to accommodate central air, modern lighting, and high-draw kitchen appliances. This complexity makes meticulous labeling non-negotiable. For a global comparison, you can see these average circuit breaker counts in homes.

The Final Safety Checklist

With wiring neat and the schedule complete, perform final checks. Fasten the dead front cover securely, ensuring no wires are pinched. This cover is a crucial safety barrier between personnel and live components.

The job is not complete until every circuit is tested. Methodically turn on each breaker and verify that the corresponding outlets, lights, or appliances are powered. This confirms the installation is correct and fully functional.

Only after this full check should the system be re-energized. This comprehensive process, from wire management to final testing, is the hallmark of a professional who prioritizes safety and quality.

Common Wiring Mistakes and How to Avoid Them

Even seasoned professionals can make mistakes. In a residential electrical panel, a minor error can lead to significant problems, compromising safety and reflecting poor workmanship. Discussing common errors is key to upholding high standards.

The most dangerous mistake is using the wrong wire gauge for a circuit's amperage. A 20A circuit on a wire rated for only 15A will overheat, melting its insulation and creating a severe fire hazard. Always cross-reference your charts with local codes (e.g., DEWA, KSA Building Code) to match wire size to breaker rating.

Another critical error is improper torquing of connections. A loose connection on a neutral bus bar or breaker creates high resistance, leading to heat buildup—a primary cause of panel failures and electrical fires, especially under the heavy, constant loads of GCC homes.

Every connection has a manufacturer-specified torque value. Using a calibrated torque wrench is a non-negotiable part of a professional installation. It is the only way to guarantee a secure connection capable of handling heavy modern loads.

Troubleshooting Common Post-Installation Issues

The real test begins after the panel is energized. Efficiently diagnosing and fixing issues is a mark of expertise. An effective energy management solution for Dubai projects starts with a flawless installation.

Instant Breaker Trips

An immediate trip indicates a direct short circuit (hot wire contacting neutral or ground).

To diagnose:

- Isolate: Turn off the breaker and disconnect the hot wire.

- Test for continuity: Use a multimeter to check for continuity between the disconnected hot wire and the neutral bus bar, and then the ground bus bar. A beep confirms a short.

- Trace the fault: Inspect outlets and switches on the circuit. The cause is often a stray copper strand or a pinched wire.

Tracing a Dead Circuit

If a circuit is dead with no tripped breakers, it could be a faulty breaker, a loose wire in the panel, or a downstream break.

Begin troubleshooting at the source. Use a multimeter to test the load-side screw on the circuit breaker. If voltage is present, the problem lies downstream in the circuit.

A solid diagnostic process is crucial. For an in-depth look at components that prevent these issues, review our guide on electrical protection equipment.

Answering Your Top Wiring Questions

Certain questions about residential electrical panel wiring are common among engineers and electricians across the UAE. Here are answers to some of the most frequent queries our team at GoSwitchgear receives.

How Do I Determine the Correct Panel Size for a New Dubai Villa?

Sizing a panel requires a meticulous load calculation based on the villa's total area, all major appliances (especially high-tonnage AC units), kitchen equipment, and water heaters.

Pro Tip: Always factor in future demand, such as EV chargers or swimming pools. For most new high-end homes in Dubai, a 200A panel is now the baseline. Anything less is insufficient for modern cooling loads and amenities. A certified engineer must perform the calculation based on the latest DEWA guidelines to ensure compliance and adequate capacity.

What Are the UAE Requirements for Arc Fault Circuit Interrupters (AFCIs)?

While GFCI protection is mandatory in wet locations (kitchens, bathrooms), the use of Arc Fault Circuit Interrupters (AFCIs) is rapidly becoming standard. The UAE is aligning with international safety codes (like the NEC), making AFCI protection the norm for circuits in living areas and bedrooms. AFCIs detect dangerous arcing faults that standard breakers miss, preventing fires.

Always check the most current regulations from local authorities like the Dubai Municipality or Abu Dhabi's Department of Energy, as these standards are updated regularly.

Can I Use Aluminium Wiring for Branch Circuits?

The answer is a definitive no. While larger-gauge aluminum conductors may be used for main service entrance feeds, they are not permitted for smaller branch circuits (lights, outlets) in modern residential construction across the UAE.

Copper offers superior conductivity, lower resistance, and does not pose the same risk of oxidation at connection points—a significant fire hazard with aluminum. For a safe, code-compliant installation that ensures long-term reliability, use copper wire exclusively for all branch circuits.

Technical expertise is just one part of a successful business. For those running their own electrical contracting company, exploring effective marketing strategies for electricians can help secure more high-value projects.

For project support in Dubai or a quote for your Abu Dhabi development, reach our technical team for expert advice on selecting the right electrical components in the UAE.

Leave a Reply