Star-Delta Starters: A Guide for UAE & GCC Industries

High inrush currents from large motors can destabilize electrical grids, causing voltage dips and mechanical stress. For industries across the UAE and GCC, where powerful HVAC, pumping, and manufacturing systems are essential, a reliable motor starting solution isn't a luxury—it's a necessity to ensure operational stability and compliance with strict utility regulations. This is where the star-delta starter proves its value.

Why a Star-Delta Starter is Crucial for UAE Industries

Across the UAE and the wider GCC, large induction motors are the unsung heroes of industry. They're the workhorses powering everything from the massive HVAC systems that keep our skyscrapers cool to the critical pumps in water treatment plants and the heavy machinery in manufacturing hubs. But firing up these powerful motors isn't as simple as flipping a switch.

When a large induction motor starts directly online (DOL), it demands an enormous surge of power known as inrush current—often six to eight times its normal running current. This sudden spike can cause serious voltage dips across the entire electrical network.

For any facility in Dubai or Abu Dhabi, this is a major headache. It can disrupt sensitive electronics, trip circuit breakers, and even lead to hefty penalties from utility providers like DEWA and ADDC, who enforce strict grid stability standards. The extreme heat and dust in the region also put additional stress on electrical components, making a controlled, gentle start even more critical.

The Two-Stage Solution for Motor Protection

The genius of the star-delta starter is its simple yet highly effective two-stage approach to taming this initial power surge. It's a bit like a car's gearbox, easing the motor into motion before shifting into high gear.

Stage 1: The Star Connection

Initially, the starter wires the motor windings into a 'star' (Y) shape. This simple trick reduces the voltage across each winding to just 58% of the full line voltage. As a result, both the starting current and torque are slashed to about one-third of what they’d be in a direct-on-line start. This "soft start" lets the motor accelerate smoothly, without putting a sudden strain on the power grid or the machinery it's connected to.Stage 2: The Delta Connection

After a pre-set time—once the motor is up to about 75-80% of its full speed—a timer triggers the switchover. The star contactor opens, and the delta contactor closes, instantly reconfiguring the windings into a 'delta' (Δ) connection. This applies the full line voltage, letting the motor run at its maximum rated power and efficiency.

For panel builders and maintenance engineers in the GCC, this controlled startup is non-negotiable. It means less mechanical shock on gears and belts, a more stable power grid, and a much longer, healthier life for expensive motor assets. GoSwitchgear supplies the high-quality, IEC-certified contactors and timers essential for building these reliable, long-lasting starter systems that can withstand the demanding local climate.

How a Star Delta Connection Protects Your Motor

To really get why a star-delta starter is such a vital piece of kit, you need to understand the clever three-step dance it performs every time a motor starts. This isn't just flipping a switch; it's a carefully timed sequence of connections designed to ease a three-phase motor into action, preventing the kind of electrical and mechanical shock that comes with a brute-force direct start.

The whole process is managed by a few contactors and a timer, unfolding in three distinct stages. This controlled sequence is what makes it a workhorse in demanding industrial environments across the UAE.

Phase 1: The Initial Star Connection

The startup sequence kicks off by connecting the motor's six terminals in a 'star' (also called 'wye' or Y) pattern. This happens when the main contactor and the star contactor pull in, effectively shorting three of the winding ends together to create a common neutral point.

This simple reconfiguration is the magic behind the soft start. In the star connection, the voltage pushed across each motor winding is slashed to about 58% of the full line voltage (that’s Line Voltage / √3).

This voltage drop has a massive impact. Based on Ohm's Law, both the starting current and the torque are knocked down to about one-third (33%) of what you'd get with a Direct-On-Line (DOL) start. For a big pump or fan in a Dubai facility, that’s the difference between a smooth, controlled spin-up and a violent, damaging jolt.

Phase 2: The Critical Transition Period

Once the motor is up and running, reaching about 75% to 80% of its full rated speed, the starter gets ready to switch into high gear. This transition is the most delicate part of the whole operation, and it's all controlled by a dedicated timer in the control circuit.

The timer's only job is to create a tiny pause—we're talking milliseconds—between disconnecting the star connection and engaging the delta connection.

This momentary break is absolutely critical for safety. It gives the star contactor just enough time to fully open before the delta contactor closes, preventing a catastrophic short circuit right across the three-phase supply. An incorrectly set timer is one of the most common reasons these starters fail.

Phase 3: The Final Delta Connection

After that brief pause, the timer gives the delta contactor the green light. It closes, reconfiguring the motor windings into a 'delta' (Δ) shape, where each winding is now connected end-to-end, forming a closed loop.

In this final setup, the full line voltage is applied directly across each motor winding. The motor can now produce its full rated torque and power, ready to handle its intended load. It will keep running in this high-performance mode until it's switched off.

This seamless, three-step sequence brings some huge advantages for panel builders and facility managers across the GCC:

- Reduced Mechanical Stress: That gentle start goes easy on couplings, gearboxes, and belts, making all the mechanical parts last much longer.

- Enhanced Electrical Stability: By keeping that massive inrush current in check, the starter prevents voltage dips that could mess with other sensitive equipment on the same power line.

- Increased Motor Longevity: Less electrical and heat stress during startup means the motor itself has a longer, more reliable life. Star-delta connections are built specifically to protect industrial electric motors from the harsh realities of startup, and knowing which motor you have is key to using them correctly.

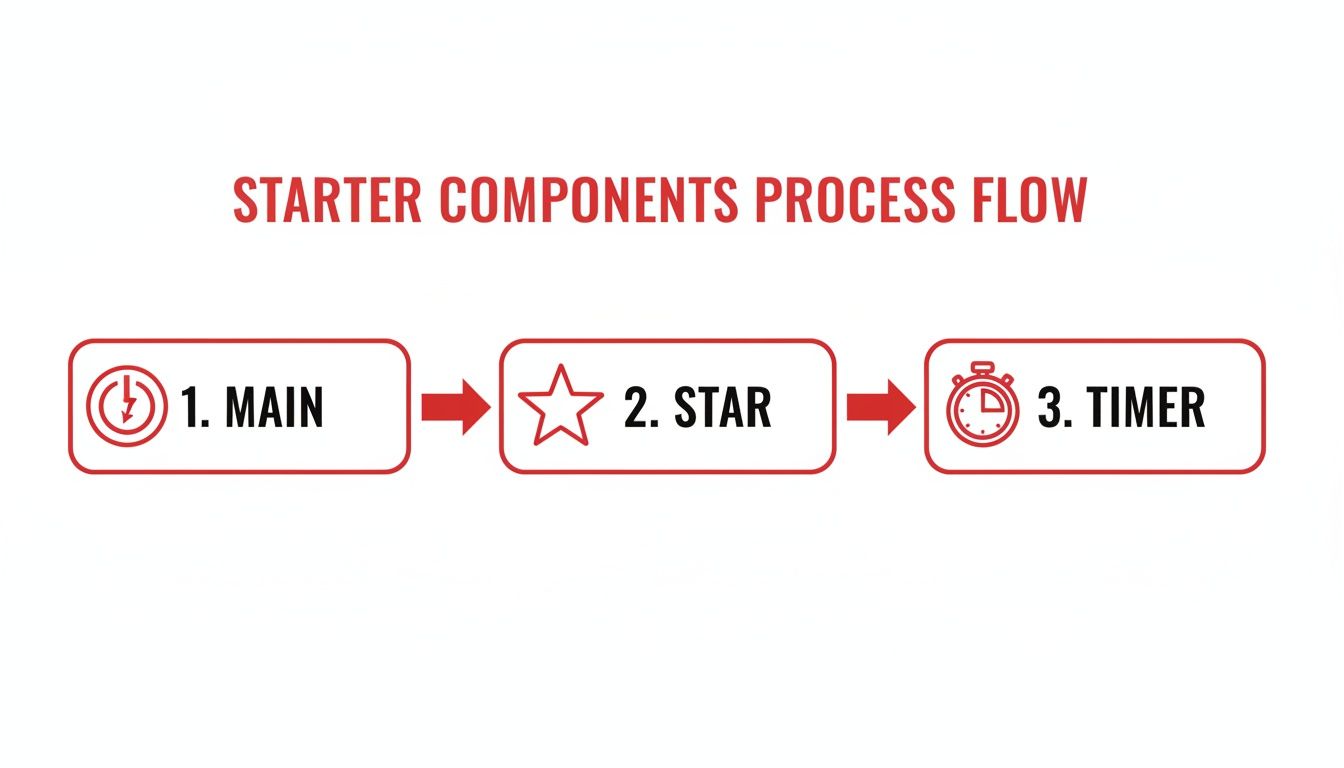

Breaking Down the Core Starter Components

A star-delta starter isn't just one component; it's a team of parts working in perfect sync. For panel builders and procurement teams here in the UAE, really getting to grips with this assembly is the secret to building motor control solutions that are reliable and built to last. Let's pull it apart and see how each piece fits into the puzzle.

At its core, the starter relies on three main switching devices and two crucial control elements. The quality you choose for these parts directly dictates how well the starter performs, especially in the tough, high-temperature, and dusty environments we see all across the GCC.

The Power Trio: The Main, Star, and Delta Contactors

The real muscle work in a star-delta starter is handled by a set of three contactors. Each one has a very specific job to do during the startup sequence.

The Main Contactor (KM1): Think of this as the primary workhorse. It kicks in the second the motor starts and stays engaged the entire time, through both the star and delta phases. It works hand-in-hand with the other two contactors to make sure power goes where it needs to.

The Star Contactor (KM2): This one has a short but vital role. It's only active during that initial startup period. Its single job is to connect the three motor winding ends (W2, U2, V2) together, which creates the star point. This is the magic that allows for that gentle, low-current start.

The Delta Contactor (KM3): Once the motor is up to speed, the star contactor steps back, and the delta contactor takes the stage. It reconfigures the windings into a delta formation, unleashing the motor's full running power. Since it handles the full operational current, its quality is every bit as critical as the main contactor's.

For rock-solid performance, sourcing high-quality, IEC-certified components is non-negotiable. You can learn more about selecting the right Schneider Electric contactor options for your projects, ensuring your builds meet all local regulatory standards.

The Brains of the Operation: The Timer and Overload Relay

While the contactors are doing the heavy lifting, two other components are in charge of control and protection. They make sure the sequence happens correctly and safely, every single time.

1. The Timer Relay

The timer is arguably the single most critical control component in the entire starter. It's the conductor of the orchestra, dictating exactly how long the motor runs in the star connection, which is usually just a few seconds.

An incorrectly set timer is one of the biggest reasons these starters fail. Switch over too soon, and the motor hasn't hit the right speed, causing a massive current spike. Wait too long, and you're running the motor inefficiently in star mode, letting unnecessary heat build up. A top-quality, easily adjustable timer isn't a luxury; it's a necessity for a reliable system.

2. The Thermal Overload Relay

This is the motor's personal bodyguard. It's wired in series with the main contactor, and its job is to constantly watch the current the motor is pulling.

If the motor starts drawing too much current for too long—maybe because of a mechanical jam—the overload relay trips. This immediately opens the control circuit, cutting power to all the contactors and safely shutting the motor down before its windings can overheat and get permanently fried.

Why Component Quality Matters in the UAE Climate

Here in the UAE and KSA, the combination of high ambient temperatures and airborne dust puts a huge amount of stress on electrical gear. This makes sourcing your parts from a trusted supplier absolutely vital.

- IP Ratings: Always look for contactors and enclosures with high Ingress Protection (IP) ratings, like IP54 or better. This is your first line of defense against dust and moisture getting in.

- Temperature Derating: Make sure your components are either rated for high ambient temperatures (often up to 55°C) or are properly derated for the conditions. Ignoring this is a surefire way to cause premature failure.

- Certifications: Don't even consider parts that aren't IEC certified and compliant with local utility rules (DEWA, ADDC, etc.). It's a fundamental requirement.

By being picky and choosing robust, correctly rated components from a reliable electrical components UAE supplier, you're not just building a star-delta starter that works—you're building one that will stand up to the harsh realities of the GCC's industrial environment.

Mastering the Wiring and Control Circuit Logic

The heart of any star and delta starter is its wiring. For panel builders across the GCC, from Dubai to Abu Dhabi, getting the power and control circuits spot-on isn't just about making things work—it’s a fundamental safety mandate. One slip-up here can lead to disastrous equipment failure.

If you can get your head around the logic of these circuits, the whole operation becomes crystal clear. This ensures every installation is safe, compliant, and runs like a dream from the get-go. Let’s pull back the curtain on the two critical wiring diagrams.

The Power Circuit Blueprint

Think of the power circuit as the muscle. It’s the part that handles the heavy lifting, delivering the high currents needed to get the motor spinning. Its job is to connect the three-phase supply to the motor's six terminals (U1, V1, W1 and U2, V2, W2) through the three main contactors.

The wiring is laid out to create two distinct motor winding connections:

Star Configuration: At startup, the main contactor (KM1) and the star contactor (KM2) pull in. KM2 is the key here—it shorts the U2, V2, and W2 terminals, creating a common neutral point. This applies a reduced voltage to the motor for a smooth, soft start.

Delta Configuration: After a set time delay, the star contactor (KM2) drops out. A moment later, the delta contactor (KM3) closes, reconfiguring the windings end-to-end (U1 to W2, V1 to U2, W1 to V2). This switchover applies the full line voltage, and the motor settles into its normal running state.

This simple flow diagram shows how the main components work together in sequence.

As you can see, it's a logical progression: the main and star contactors engage first, and then the timer dictates the switch to the delta contactor.

The Control Circuit Logic

If the power circuit is the muscle, the control circuit is the brain. It runs at a much lower voltage, and its entire purpose is to manage the precise timing and interlocking of the contactors. The most critical part of this logic is preventing the star (KM2) and delta (KM3) contactors from ever being closed at the same time. If that happened, you'd have a dead short across the power lines. Game over.

The control circuit is designed to be foolproof. For a deeper dive into the components that drive these circuits, check out our Control Transformer Guide.

The absolute linchpin of the control logic is the 'break-before-make' transition. The timer has to enforce a definite, if brief, pause between the star contactor switching off and the delta contactor switching on. This tiny gap is what prevents arcing and catastrophic short circuits that can wreck the whole system.

To give panel builders a clear, step-by-step roadmap, we’ve broken down the operational sequence in the table below. Following this logic to the letter is the key to a safe and reliable startup, every single time.

Star Delta Starter Operational Sequence

This table lays out the exact state of each component during the four distinct phases of the starter’s operation.

| Phase | Main Contactor (KM1) | Star Contactor (KM2) | Delta Contactor (KM3) | Timer Status |

|---|---|---|---|---|

| OFF | De-energized | De-energized | De-energized | Inactive |

| Star Start | Energized | Energized | De-energized | Timing |

| Transition | Energized | De-energized | De-energized | Timer Expired |

| Delta Run | Energized | De-energized | Energized | Inactive |

Memorizing this sequence is essential. It’s the fundamental logic that ensures a star delta starter functions correctly and safely from the moment you press the "start" button.

How to Correctly Size Your Star and Delta Starter

Picking the right components for a star and delta starter isn't as simple as just matching the motor's kilowatt rating. For engineers and panel builders across the UAE, getting the sizing right is a fundamental skill. It’s what separates a reliable, long-lasting system from one plagued by constant issues. The whole process hinges on a methodical approach, starting with the motor's nameplate data—specifically its Full Load Current (FLC).

Nail this, and you avoid premature component failure, frustrating nuisance trips, and a motor that just doesn't run efficiently. In the GCC’s booming industrial landscape, these starters are the workhorses for managing large motors. It's a growing field, too; the Middle East and Africa motor starters market is a key part of a global industry expected to hit USD 12.8 billion by 2034. You can read more about the growth of the motor starters market to see just how critical this technology is becoming.

Sizing the Main and Delta Contactors

Let's start with the heavy lifters: the main contactor (KM1) and the delta contactor (KM3). These two handle the full operational current once the motor is up to speed and running in its delta configuration.

A common mistake is to assume they carry the full line current. They don't. Instead, they handle the phase current flowing through the motor windings.

The industry-standard formula for these two is straightforward:

Main/Delta Contactor Rating = 58% of Motor FLC (Full Load Current)

This figure comes from the 1/√3 calculation of the FLC. So, for a motor with an FLC of 100A, your main and delta contactors need to be rated for at least 58A.

Here’s a pro tip for anyone working in the GCC: always pick the next standard contactor size above your calculated value. This builds in a crucial safety margin to handle the high ambient temperatures and voltage swings we often see, ensuring the components aren't constantly pushed to their absolute limit.

Sizing the Star Contactor

The star contactor (KM2) has a much easier job. It’s only engaged during that initial startup sequence when the current is drastically lower. The current it sees is just one-third of the motor's FLC.

The formula here is just as simple:

Star Contactor Rating = 33% of Motor FLC

Using that same 100A motor, the star contactor only needs a 33A rating. This is a great place to optimize costs by using a smaller, more economical component without ever compromising on safety or performance. For related protection calculations, tools like GoSwitchgear's breaker size calculator can be incredibly helpful.

Sizing Example: A 30 kW Motor

Let's put this into practice with a scenario you'd find all over Dubai's industrial zones.

- Motor: 30 kW, 415V, 0.85 Power Factor

- Calculated FLC: Roughly 52A

Now, let's size the contactors step-by-step:

Main & Delta Contactors (KM1 & KM3):

52A x 0.58 = 30.16A- What to do: Don't cut it close. Choose the next standard size up. Depending on the manufacturer, that will likely be a 32A or even a 40A rated contactor.

Star Contactor (KM2):

52A x 0.33 = 17.16A- What to do: A standard 18A or 20A contactor is the perfect fit here.

Setting the Overload Relay and Timer

Sizing the contactors is only half the battle. Setting your protection and control timers correctly is just as critical to get right.

Overload Relay: This is a key detail many people miss. The thermal overload relay is wired in the main line but must be set to protect the motor's phase windings, not the full line current. That means you set it to 58% of the motor's FLC. For our 52A motor, the setting would be

52A x 0.58 = 30.16A.Timer: The timer setting dictates the transition from star to delta. You need to give the motor enough time to reach about 75-80% of its full speed before making the switch. For most standard loads, 5 to 10 seconds is usually enough. But for high-inertia loads—think large ventilation fans or the big centrifugal pumps common in the UAE—you may need to push that to 15-20 seconds to guarantee a smooth transition and prevent a damaging current spike.

Troubleshooting Common Star Delta Starter Faults

No matter how well-built or perfectly installed it is, every star and delta starter will eventually run into a snag. For the maintenance engineers on the front lines in the UAE's demanding industrial facilities, getting things back online quickly isn't just a goal—it's essential. Knowing where to look when a starter acts up is the key to cutting downtime and keeping critical machinery running.

This guide is a practical, no-nonsense checklist for the most common faults you'll encounter. We’ll get straight to the likely causes and give you clear, actionable steps to get your system running safely again.

Issue 1: Motor Fails to Start

You hit the start button, and… nothing. It's a classic scenario, and the culprit is almost always hiding in the control circuit. Before you start thinking about big component failures, let's check the basics first.

Common Causes & Solutions:

- No Control Voltage: Is the control circuit even getting power? Grab a multimeter and check your main supply. Verify voltage at the control transformer and the circuit's fuse or breaker.

- Faulty Push Buttons: The start/stop buttons get a lot of use, and their connections can work loose or the internal contacts can fail. Test for continuity across the terminals as you press and release the buttons.

- Overload Relay Tripped: This is a safety feature doing its job. A tripped overload relay opens the control circuit, preventing the motor from starting. Find the relay, figure out why it tripped (like a mechanical jam), and reset it after clearing the fault.

- Loose Wiring: Never underestimate the power of vibration. Over time, connections in industrial settings can loosen. A quick visual inspection and tightening of all control circuit terminals is a simple but surprisingly effective first step.

Issue 2: Motor Trips During the Star-to-Delta Switch

This is probably one of the most frustrating faults. The motor starts up fine, but the instant it tries to switch from star to delta, the main breaker or overload relay trips. This points to a massive current spike right at the changeover point.

Common Causes & Solutions:

- Incorrect Timer Setting: This is the number one cause, hands down. If the timer is set too short, the motor hasn't spun up to the right speed (around 75-80% of its full speed) before the switch happens. The motor is essentially caught off guard, leading to a huge inrush of current that trips the protection.

- Solution: Simply increase the timer delay. Do it in small increments to give the motor a bit more time to accelerate while in the star connection.

- Mechanical Interlock Failure: The physical interlock that prevents the star and delta contactors from closing at the same time might be worn out or damaged. If both engage, even for a split second, you have a dead short.

- Solution: Power down completely and lock out the system. Manually inspect the interlock mechanism. If it looks worn, damaged, or sloppy, it's time to replace it.

Issue 3: Motor Runs in Star but Won't Switch to Delta

The motor hums along nicely in the star configuration, but the timer clicks over and… nothing happens. It just keeps running in star. The problem is almost certainly within the control logic that's supposed to energize the delta contactor.

A failure to transition to delta leaves the motor severely underpowered and at risk of overheating if left running under load. It's a condition that requires immediate attention to prevent motor damage.

Common Causes & Solutions:

- Faulty Timer Relay: The timer itself might be the issue. The internal contacts that are supposed to send power to the delta contactor coil could be shot. After the set time has passed, use your meter to check for voltage at the timer's output terminal.

- Defective Delta Contactor Coil: The coil for the delta contactor (often labeled KM3) could be burnt out or have an open circuit. Safely isolate the power and check the coil's resistance with a multimeter. An infinite reading means the coil is dead and needs replacing.

- Broken Electrical Interlock: As a safety measure, a normally closed auxiliary contact from the star contactor is wired into the delta contactor's coil circuit. This ensures the delta contactor can't pull in while the star contactor is engaged. If this auxiliary contact is broken or stuck open, it will never allow power to reach the delta coil. Test it to make sure it's operating correctly.

Sizing Up Your Options: Modern Motor Starting Solutions

The star-delta starter has long been the go-to workhorse for panel builders in the UAE, and for good reason—it’s reliable and budget-friendly. But today’s projects demand more, and it’s crucial to know how this classic stacks up against newer technologies. The right choice always comes down to balancing three key factors: cost, control, and efficiency.

Let's break down the differences between the trusted star-delta starter and its modern cousins: soft starters and Variable Frequency Drives (VFDs).

Even with advanced alternatives available, the star-delta starter holds its ground, especially in the UAE's renewable energy boom. Think about large-scale solar PV projects; these starters get massive pumps running without putting a sudden, heavy strain on the grid. Its market relevance is clear—globally, star-delta is projected to capture around 38% of the automatic motor starters segment in 2025, a market valued at USD 367 million. This continued trust is a testament to its effectiveness in initiatives like Masdar City's ambitious net-zero goals. You can dive deeper into the automatic motor starters market trends here.

Key Differences at a Glance

For system integrators and panel builders in the GCC, the decision really boils down to the specific job at hand. The star-delta starter offers rugged simplicity that just works. A VFD, on the other hand, gives you unparalleled control over motor speed and performance. Stuck in the middle? The soft starter is often the perfect compromise, giving you a much smoother start-up than star-delta without the higher cost and programming complexity of a VFD.

To help you make the call for your next project in Dubai, Abu Dhabi, or anywhere in the region, here's a side-by-side look at how they compare.

Comparison of Motor Starting Methods

| Feature | Star-Delta Starter | Soft Starter | Variable Frequency Drive (VFD) |

|---|---|---|---|

| Starting Current | Reduced to ~33% of DOL | Stepless reduction, fully adjustable | Fully controlled, stepless ramp |

| Mechanical Stress | Reduced, but with a transition jolt | Very smooth, gradual acceleration | Smoothest possible start and stop |

| Speed Control | No speed control (fixed speed) | No speed control during run | Full speed control (0-100%+) |

| Energy Efficiency | High efficiency during run | High efficiency during run | Highest, especially at reduced speeds |

| Initial Cost | Low | Moderate | High |

| Complexity | Low to moderate | Moderate | High (requires programming) |

So, what's the verdict? It all comes back to your project's needs. If you're working on a straightforward, fixed-speed application like a pump or a fan where the budget is tight, the star-delta starter is still an unbeatable choice. It's a proven solution that delivers reliable performance without breaking the bank, making it a powerful energy management solution Dubai and other GCC cities can rely on.

For all your project needs, from reliable star-delta components to advanced VFD solutions, explore the extensive catalogue at GoSwitchgear. Reach our Dubai team for project support or to request a quote for your Abu Dhabi projects. Find the right electrical components for your UAE and GCC projects at https://goswitchgear.ae.

Leave a Reply