Everything You Need to Know About Voltage Transducers for Electrical Monitoring

For engineers and panel builders in the UAE, managing advanced electrical systems—from data centers in Dubai to industrial plants in Abu Dhabi—requires clear, reliable data. The control devices at the heart of these systems, like PLCs and SCADA, need a simple way to understand what’s happening with the power supply. A voltage transducer is the essential translator in this critical process.

What Is a Voltage Transducer and Why Is It Critical?

Imagine trying to describe a complex symphony to someone who only understands a few basic musical notes. That's essentially the job of a voltage transducer in an industrial or commercial facility. It bridges the communication gap between raw, high-level AC voltage and the simple, low-voltage DC language that modern automation systems speak.

This "translation" is fundamental for safe and efficient operations in the demanding GCC climate. Without a reliable voltage transducer, the PLCs, building management systems (BMS), and SCADA systems that run everything would be completely blind to the health of their own power supply, putting valuable equipment at risk from heat, dust, and electrical instability.

The Core Functions of a Voltage Transducer

At its heart, a voltage transducer is a key component for any modern energy management solution Dubai. Let’s break down its essential functions.

| Function | What It Does | Why It Matters in the GCC |

|---|---|---|

| Conversion | Takes a variable AC voltage input (typically 57V to 500V) and transforms it into a proportional, industry-standard DC output. | In a region with high-demand infrastructure, this provides the clean, usable data needed for sophisticated energy management and automation. |

| Isolation | Creates a safe electrical barrier between the high-voltage power circuit and the sensitive, low-voltage control circuit. | This protects high-value control equipment and maintenance staff from the risk of dangerous electrical faults in demanding, high-temperature environments. |

| Transmission | The standardized signal (e.g., 4–20mA) can be reliably sent over long distances without significant signal loss or interference. | Critical for large facilities like airports, malls, and industrial zones in the UAE, where control rooms can be far from the actual switchgear. |

This capability acts as the first line of defense for maintaining uptime and protecting valuable assets. By providing real-time, accurate voltage data, these transducers allow automated systems to spot dangerous conditions—like sags, swells, or phase loss—before they trigger a catastrophic failure.

If you'd like to get into the weeds of how different transducers operate, you can explore our comprehensive transducer guide.

A voltage transducer isn't just another component; it's what gives an electrical panel its intelligence. It provides the "senses" the system needs to monitor its own health, react to problems, and ultimately optimize its performance, which is vital for any of the electrical components UAE businesses rely on.

The growing need for these devices is clear from market trends. The global voltage transducer market was valued at USD 1.4 billion in 2025, with forecasts showing it could hit USD 2.8 billion by 2035. In the UAE, this growth is fueled by rapid urbanization and massive infrastructure projects. Since the region's power grids are predominantly AC, the demand for AC voltage transducers is especially high. You can learn more about the industrial voltage transducer market growth and what's driving it.

Choosing the Right Voltage Transducer Model

Picking the right voltage transducer isn't just a small technical detail; it’s a decision that directly affects system reliability and data accuracy. For engineers and procurement teams in the UAE and across the GCC, this choice goes beyond simply matching voltage ratings. You have to consider the operational and data requirements of the project, especially given the region’s climate challenges like heat and dust, which demand high-quality, certified components.

The truth is, not all transducers are built the same. Understanding the key differences is what separates a robust, efficient electrical monitoring system from one that might cause headaches down the road.

Often, the decision boils down to a trade-off between simplicity, redundancy, and data connectivity. Let's break down the common types you'll encounter, from foundational models to the advanced, communicable devices perfect for today's smart panels.

Standard Single-Output Models for Core Applications

The most common option is the single-output analog voltage transducer. These are the workhorses of industrial control, designed to do one job exceptionally well: convert an AC voltage input into a single, standardized analog output signal, either 4–20mA or 0–10V. These are universal languages that most PLCs, VFDs, and control units understand.

- When to Use Them: Single-output models are perfect for simple control loops where the main goal is direct monitoring or basic protection, like monitoring supply voltage to a critical motor or feeding a basic reading to a local display on a control panel.

- Benefits: Their simplicity is their strength. They are reliable, cost-effective, and easy for panel builders to install and troubleshoot—a huge plus for projects in Dubai and across the GCC where efficiency is key.

Dual-Output Models for Enhanced Redundancy

In critical systems, a single point of failure is unacceptable. This is where dual-output voltage transducers shine. These devices take a single voltage input but provide two independent and isolated analog outputs. This design gives you essential redundancy. For instance, one output (e.g., 4–20mA) can go to the main PLC or SCADA system for operational management, while the second (e.g., 0–10V) can be wired to a separate alarm system or data logger.

If the primary control loop fails, the secondary system continues monitoring the voltage. This is vital for applications like generator monitoring in hospitals or data centers where downtime is not an option.

Smart Transducers with Modbus for System Integration

The push for smart buildings and Industry 4.0 in Dubai and the wider GCC has brought smart transducers with Modbus/RS485 communication to the forefront. While still providing a standard analog output, their game-changing feature is sending data digitally over a serial network. A single Modbus-enabled device can report multiple data points—like voltage, frequency, and device status—over a simple two-wire connection, streamlining panel wiring and reducing complexity.

These smart transducers integrate seamlessly into advanced BMS, energy management platforms, and SCADA systems. For a facility manager in Abu Dhabi, this means deeper insights into power quality without wiring dozens of individual analog inputs.

At GoSwitchgear, we stock pre-configured transducers from trusted brands like Rishabh and Multispan to meet any requirement, ensuring fast UAE-wide delivery for your projects.

How Voltage Transducers Drive UAE Industries

The real value of a voltage transducer shines on the factory floor, in the server room, or deep within a city's power grid. These components are unsung heroes in countless critical jobs across the UAE and GCC, working silently to prevent expensive failures and boost operational intelligence. For any modern voltage transducer application, from simple protection to sophisticated automation, they are absolutely essential.

Here’s a look at where these devices make a tangible difference every day for facility managers, panel builders, and engineers in Dubai, Abu Dhabi, and beyond.

Guarding Distribution Panels

The Main Distribution Panel (MDP) or Sub-Main Distribution Panel (SMDP) is the central nervous system of a building's electrical network. Here, a voltage transducer acts as a tireless sentinel. Its main job is voltage monitoring in panels, watching constantly for:

- Voltage Sags (Brownouts): Sudden dips can cause motors to struggle and computers to crash, leading to lost production and corrupted data.

- Voltage Swells (Overvoltage): Spikes can permanently fry the sensitive electronics in your most expensive machinery.

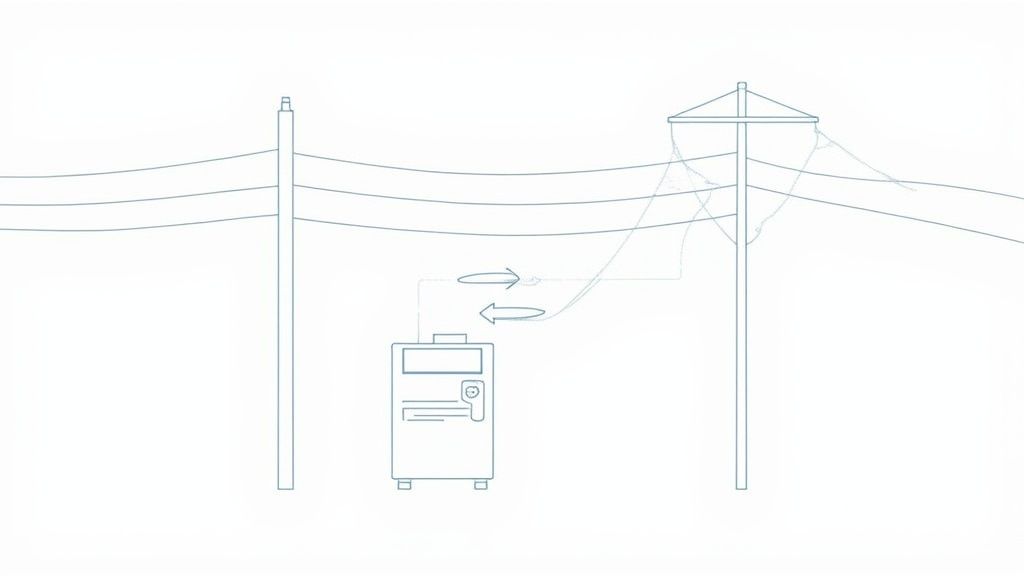

By converting raw AC voltage into a clean 4-20mA signal, the transducer sends a steady stream of health updates to a PLC or BMS. If the voltage strays outside safe limits, the system can instantly trigger an alarm or isolate sensitive equipment.

Ensuring Generator Set Stability

In a region where consistent power is a must, generator sets are the ultimate safety net. A voltage transducer application is key here. It monitors the generator's output, confirming that the voltage has stabilized at the correct level and frequency before the Automatic Transfer Switch (ATS) connects it to the building's load. This simple check prevents damaging "hard starts" and ensures a smooth, safe transfer of power.

Precision Control in Industrial Machinery

From CNC machines in Sharjah to packaging lines in Jebel Ali, modern machinery demands absolute precision. An unstable voltage can throw off motor speeds, alter heating element temperatures, and ruin the accuracy of robotic arms. By using an analog voltage converter to send real-time data back to the machine’s controller, operators can guarantee process consistency, slash defect rates, and boost quality.

Across the Middle East and Africa, the need for both voltage and current transducers is climbing. This trend is fueled by a strong regional push for better energy efficiency and power quality. These devices are the foundation for tracking consumption and spotting waste, which lines up perfectly with the UAE's national goals to cut power usage and build a more resilient infrastructure. You can learn more about these trends in transducer demand and their wider impact.

Ultimately, these devices do more than just measure voltage—they're a cornerstone for building smarter, more resilient electrical systems. By turning raw voltage into clean, actionable data, they help facilities shift from reactive maintenance to proactive management. This is a critical step for anyone serious about implementing robust energy efficiency solutions that deliver genuine savings and operational wins.

Your Step-by-Step Selection Checklist

Picking the right voltage transducer is a critical decision that impacts your system's reliability, data accuracy, and future scalability. For panel builders and engineers in the UAE's demanding environments, getting this choice right from the start prevents costly rework and ensures flawless performance.

This checklist breaks the process down into four straightforward steps. By working through these, you can confidently specify a device that perfectly fits your project, whether it's a simple control panel or a complex, integrated system.

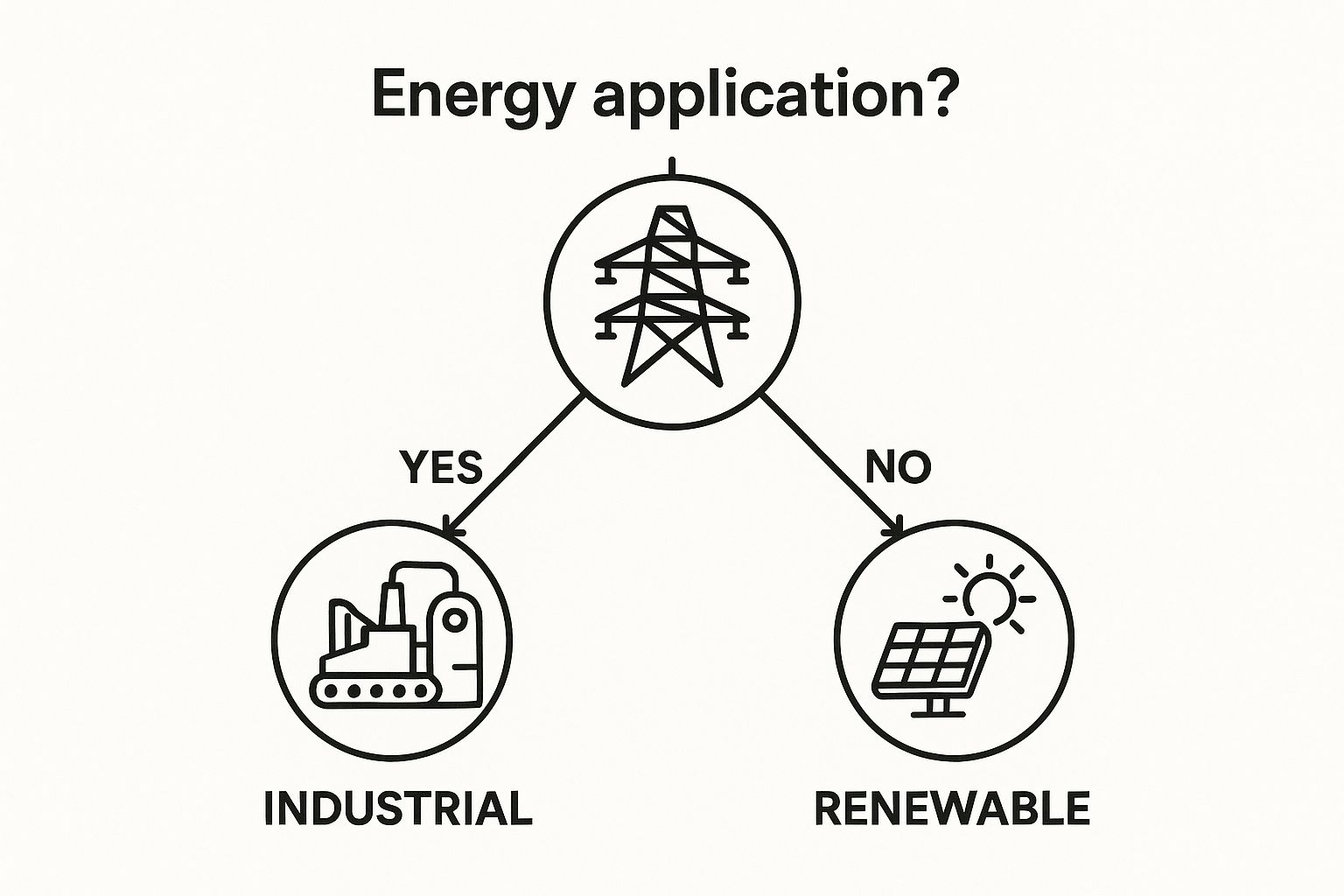

The main takeaway here is that what you're using it for, be it grid monitoring, machine control, or a solar project, heavily influences the features you'll need, like its output type and communication smarts.

1. Define Your Input Voltage Range

First, match the transducer's input range to your system's nominal voltage. A mismatch leads to inaccurate readings or a fried device.

- Standard Low Voltage: For most three-phase systems in the GCC (around 400/415V), a transducer rated for up to 500V AC provides a safe operating margin.

- Single-Phase Systems: For single-phase loads or line-to-neutral measurements, you'll need a range covering 230V AC.

- Specialized Applications: Double-check specific requirements. Setups using potential transformers (PTs) may step voltage down to 110V AC before it reaches the transducer.

Pro Tip: Always select a transducer with a maximum input rating comfortably above your system's highest expected voltage. This buffer accounts for potential swells and is crucial for longevity in harsh conditions.

2. Choose the Required Output Signal

The output signal is the "language" your voltage transducer speaks to your PLC or control system.

- 4–20mA (Current Loop): The industrial workhorse. Its excellent noise immunity makes it perfect for electrically noisy environments with VFDs or large motors. It also holds up over long cable runs. The "live zero" of 4mA instantly confirms the connection is healthy, simplifying troubleshooting.

- 0–10V (Voltage Signal): A simpler option for shorter cable runs where electrical noise isn't a major concern, common in localized control panels where the transducer is close to the controller.

The process of converting AC voltage to 4-20mA is a fundamental function of signal conditioning. It ensures the data arriving at your control system is clean, stable, and reliable.

3. Select the Installation Format (DIN rail/Wall Mount)

How and where the transducer will be installed impacts panel design and assembly time. The most common format is the DIN rail mount. This standardized design allows for quick, snap-on installation inside control panels, keeping everything neat and organized. In the GCC, where panel space is often at a premium, DIN rail components are the go-to for efficient and clean builds.

4. Assess Display and Communication Options

Finally, consider what else you need from your transducer beyond basic voltage monitoring in panels.

- Local Display: Does a technician need to see a voltage reading at the panel without a multimeter? A model with a built-in display saves time during commissioning and diagnostics.

- Modbus/RS485 Communication: For smart panels and integrated systems, a transducer with Modbus is a must-have. It sends multiple data points over a single network, drastically cutting wiring complexity and providing richer data for your SCADA or BMS, a key feature for any advanced energy management solution Dubai requires.

By carefully walking through these four areas, you can make sure the analog voltage converter you select is perfectly matched to your voltage transducer application, giving you the performance and reliability your projects demand.

Installation Best Practices and Mistakes to Avoid

Even the best voltage transducer is useless if installed poorly. For any electrician or panel builder in the UAE, a proper installation is the critical final step to ensuring a reliable and safe monitoring system. Getting it right the first time saves you from signal problems, damaged equipment, and hours of troubleshooting.

We'll cover proper wiring and mounting, and more importantly, point out the common and costly mistakes we see in panels across Dubai and Abu Dhabi. Adhere to these practices, and your voltage transducer application will deliver accurate data from day one.

Proper Wiring and Connection Techniques

The accuracy of your output signal depends on clean connections.

- Verify Input Terminals: Before connecting any wires, double-check the terminal markings on the datasheet. Accidentally connecting high line voltage to the low-voltage output side will instantly destroy the transducer.

- Use Shielded Twisted-Pair Cables: For the analog output signal (especially 4-20mA), always use shielded twisted-pair cables. Twisting cancels out electromagnetic interference (EMI), and the shield provides an extra barrier against noise.

- Correct Grounding is Essential: Ground the cable's shield at one end only, typically on the PLC or control system side. Grounding both ends creates a ground loop, which invites noise to corrupt your signal.

A classic mistake is using unshielded wire for the output signal to save costs. It's a false economy. The few dirhams saved on cable will be spent ten times over on troubleshooting a system in a noisy industrial setting.

Common Installation Mistakes to Avoid

Avoiding a few common mistakes can be the difference between a system that just works and one that's a constant headache.

Mistake 1: Mounting Too Close to Noise Sources

Variable Frequency Drives (VFDs), large contactors, and switch-mode power supplies (SMPS) are huge sources of EMI. Placing a sensitive analog voltage converter right next to them is asking for signal interference.

Solution: Keep at least 15-20 cm of space between the transducer and any high-frequency noise-makers in the panel.

Mistake 2: Using Undersized or Improper Wires

Using a wire gauge that's too small for the input voltage circuit can cause voltage drops and overheating, a serious safety risk. The wrong wire type on the output side will kill your signal integrity.

Solution: Always check the manufacturer's spec sheet for the recommended wire gauge. Ensure every terminal screw is tightened to the specified torque to avoid loose connections, a common cause of intermittent faults. Many basic principles overlap, and our guide on how to test a relay offers related insights.

Mistake 3: Poor Panel Layout and Wire Routing

Running low-voltage signal wires in the same trunking as high-voltage power cables is a surefire way to induce noise.

Solution: Practice good panel hygiene. Keep low-voltage DC signal cables separate from high-voltage AC power lines. If they must cross, do so at a 90-degree angle to minimize interference. This is a cornerstone of effective signal conditioning.

Building the Smart Grids of the Future

The conversation around individual electrical components UAE businesses use, like a voltage transducer, has grown much bigger. These devices are no longer just parts in a panel; they are essential building blocks for the ambitious national goals of the UAE and the wider GCC region.

When you choose a high-quality transducer, you're not just buying a component. You're making a strategic investment in a future-proof, intelligent, and efficient electrical infrastructure.

Accurate voltage data is the lifeblood of any modern energy management system. It enables the smooth integration of renewable energy sources and supports the massive rollout of electric vehicle (EV) charging networks—both central pillars of UAE Vision 2030 and similar initiatives across the GCC.

From Component to Cornerstone of National Vision

The push for smarter grids is happening everywhere. In Asia Pacific, the voltage transducer market is projected to make up about 35% of global revenue by 2037, driven by industrial growth and renewable energy investments. You can dig into the global voltage transducer market trends to see the bigger picture.

While the GCC is a unique market, it's following a similar path with massive plans for power generation and grid modernization. Here, a voltage transducer plays vital roles:

- Grid Stability: It delivers the real-time data needed to manage the fluctuating output from solar farms, keeping the power supply stable.

- EV Infrastructure: It acts as a watchdog for charging stations, monitoring their health to protect the grid and the vehicles.

- Demand-Side Management: It provides sharp insights for utility providers and facility managers to roll out effective, smart energy-saving programs.

The reliability of a smart grid comes down to the quality of its data. A precise and dependable voltage transducer ensures that every decision—from balancing loads to spotting faults—is based on solid, real-time information.

As voltage transducers become more connected within IoT-enabled smart grids, security becomes non-negotiable. These devices are data-gathering sensors on a huge network. This makes IoT device security a top priority for building the resilient grids of tomorrow. The integrity of our data and control systems hangs in the balance.

Ultimately, every carefully chosen analog voltage converter or smart transducer installed today is a piece of a much larger puzzle. It’s a small but critical part of building the intelligent, responsive, and sustainable electrical backbone that will power the region's growth for decades to come.

Frequently Asked Questions

Our engineers and technicians get asked a lot about voltage transducers. Here are some of the most common questions we hear, with straightforward, practical answers relevant to the GCC region.

What is the Difference Between a Voltage Transducer and a Potential Transformer?

This is a classic question. Think of it this way: a potential transformer (PT) does one job – it steps down high AC voltage to a much lower, safer level. That's it.

A voltage transducer is smarter. It also steps down the voltage, but then it goes a step further by performing signal conditioning. It converts that stepped-down voltage into a standardized DC signal, like 4–20mA or 0–10V. This is a language that PLCs and control systems understand right out of the box, which means you don't need extra signal converters cluttering up your panel.

Why Is a 4-20mA Signal Often Preferred Over a 0-10V Signal?

When you see specs for an AC voltage to 4-20mA transducer, it's for good reason. In the tough industrial environments we see across the UAE, the choice between 4-20mA and 0-10V often comes down to pure robustness and safety.

- Noise Immunity: A 4–20mA current signal is much better at resisting electrical noise and isn't affected by voltage drop, which is a big deal over the long cable runs common in large facilities.

- Live Zero: This is the game-changer. A 4mA reading confirms the transducer is powered on and correctly reading a zero value. But if you see 0mA, you know something is wrong—like a broken wire. A 0V signal, on the other hand, is ambiguous. Does it mean a zero reading, or is the power out? The 4-20mA signal makes troubleshooting faster and more certain.

Can I Use a Standard AC Voltage Transducer to Measure DC Voltage?

Simple answer: no, you can't. The vast majority of voltage transducers you'll find in control panels are built specifically for AC systems. Their internal electronics are designed to work with the sine wave of alternating current.

If you try to measure DC voltage with an AC transducer, you won't get an accurate reading, and you'll probably destroy the device. For any DC voltage transducer application, you absolutely must use a model designed for DC voltage. Always double-check the input type on the datasheet before you install anything. It's a simple step that protects your equipment and ensures your system works as intended.

For any project in Dubai, Abu Dhabi, or across the UAE, our team at GoSwitchgear is here to help you find the perfect voltage transducer. We have a huge stock of pre-configured units from top brands like Rishabh and Multispan, ready for quick delivery.

Ready to find the right transducer for your panel? Browse our full range of transducers here.

Leave a Reply